Light emitting diode possessing transparent extended electrode structure and manufacturing method thereof

A technology of light-emitting diodes and extended electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of light-emitting diode extended electrodes, shading, vulnerability to damage and falling off, etc., to increase the uniformity of current expansion, avoid electrode shading, and reliability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

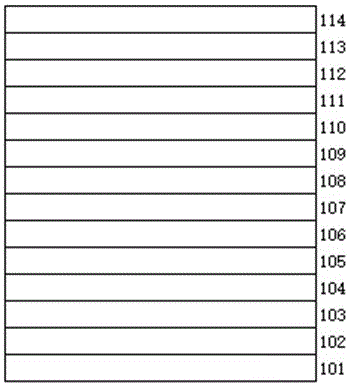

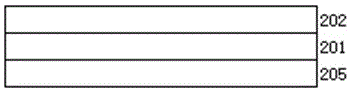

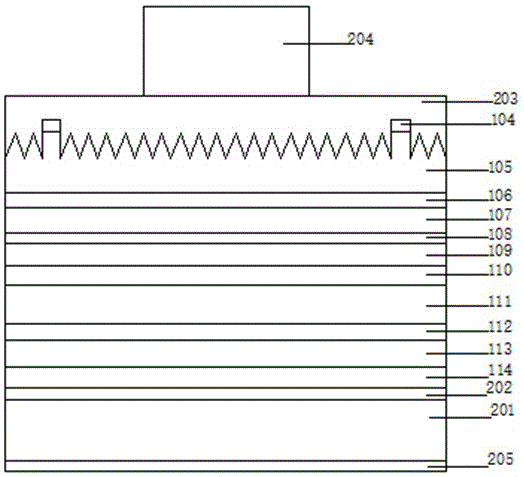

[0030] A light emitting diode with a transparent extended electrode structure comprising a permanent substrate 201 , the first metal bonding layer 202 , the second metal bonding layer 114 , specular reflection layer 113 , Dielectric film layer 112 , epitaxial light-emitting layer, extended electrodes 203 , the main electrode 204 and back electrode 205 , on a permanent substrate 201 top, permanent substrate 201 through the first metal bonding layer 202 and second metal bonding layer114 Connected with the epitaxial light-emitting layer, in the second metal bonding layer 114 There is also a specular reflective layer between the epitaxial light-emitting layer 113 and dielectric film 112 , the epitaxial light-emitting layer includes from bottom to top: P-GaP current spreading layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com