Cross-linked-polyethylene insulating optical-fiber composite three-core submarine power cable

A technology for submarine power cables and cross-linked polyethylene, which is applied in the directions of insulated cables, insulated conductors, communication cables, etc., to achieve the effects of reasonable design, simple structure, and reduced processing risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

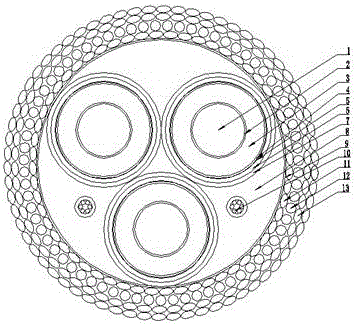

[0019] A cross-linked polyethylene insulated optical fiber composite submarine power cable includes a cable core, an optical unit 10, a reinforced filling strip 8, a wrapping tape 9, an inner lining layer 11, an armor layer 12 and an outer coating layer 13.

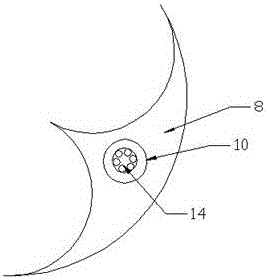

[0020] There are three cable cores distributed in a star shape, and the wrapping tape 9 is wrapped around the outer circumference of the cable cores. The reinforced filling strip 8 is filled in the cable core gap inside the tape 9 , and a reserved hole 14 is arranged on it, and the optical unit 10 is placed in the reserved hole 14 . The reinforced filling strip 8 is made of PP material, which is hard and not easy to deform. It is filled in the cable gap of the product, on the one hand, it can ensure that the cabled product is dense and round; on the other hand, it can protect and fix the optical unit. function, and ensure that the optical unit is not damaged during the laying process. In addition, the diameter of the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com