Electric heating furnace temperature control method

A temperature control method and technology of electric heating furnace, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of poor input form adaptability, less application of minimum beat control system, and insufficient control effect. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

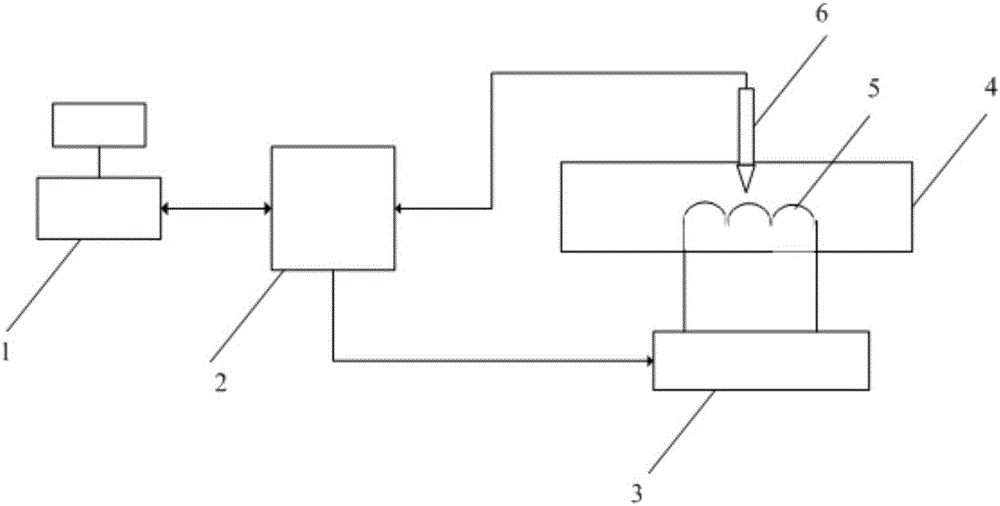

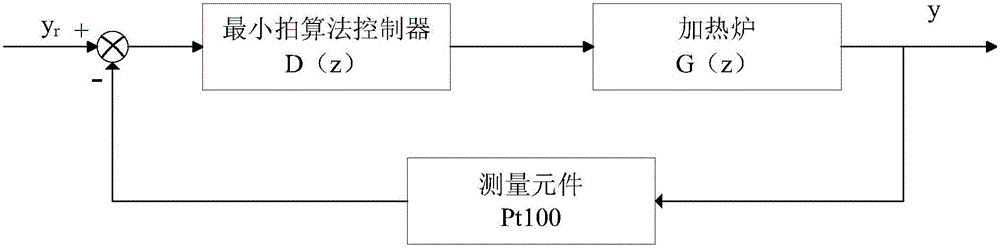

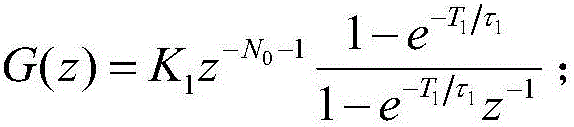

[0044] See attached figure 1 , the specific working process of the heating furnace temperature control system of the present invention is as follows: the temperature signal (0-200°C) collected by the temperature transmitter Pt100 is converted into a corresponding current signal (4-20mA), which is used as the S7-300PLC The input is sampled by the S7-300PLC and transformed into a real-time temperature value, which is transmitted to the PC that executes the control algorithm through the Ethernet. The PC calculates the control temperature according to the improved minimum beat algorithm described in the present invention. Measure u, and then transmit it to S7-300PLC through Ethernet, and the PLC performs D / A conversion on the control quantity to convert it into an analog signal (0-10V voltage signal) and output it to the voltage regulating module, and then control the resistance wire of the heating furnace The heating power finally realizes the control of the temperature of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com