An online monitoring device and monitoring method for the wear degree of the oil pipe rod

A wear level and monitoring device technology, applied in the direction of material magnetic variables, etc., can solve problems such as production lag, and achieve the effects of avoiding losses, reducing costs, and widening the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

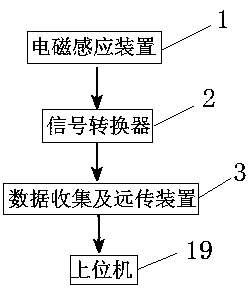

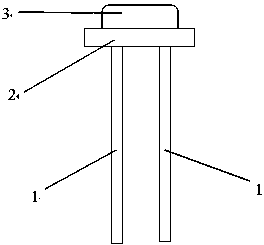

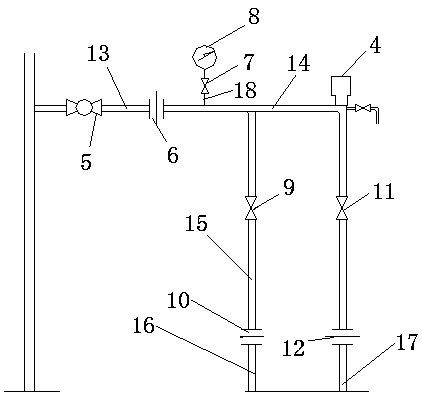

[0022] In order to solve the current problem that it is impossible to monitor the wear of oil well tubing rods online in real time, this embodiment provides such figure 1 , figure 2 The online monitoring device for the degree of wear of the tubing rod includes an electromagnetic induction device 1, a signal converter 2, a data collection and remote transmission device 3, and a host computer 19. The electromagnetic induction device 1 is installed below the signal converter 2, and It is electrically connected to the input end of the signal converter 2, and the data collection and remote transmission device 3 is installed above the signal converter 2. One end of the data collection and remote transmission device 3 is electrically connected to the output end of the signal converter 2, and the other end is connected to the output end of the signal converter 2. The upper computer 19 is electrically connected.

[0023] The electromagnetic induction device 1 is used to collect the i...

Embodiment 2

[0027] In order to solve the current problem that it is impossible to monitor the wear of oil well tubing rods online in real time, this embodiment provides such figure 1 The online monitoring device for the degree of wear of the tubing rod includes an electromagnetic induction device 1, a signal converter 2, a data collection and remote transmission device 3, and a host computer 19. The electromagnetic induction device 1 is installed below the signal converter 2, and It is electrically connected to the input end of the signal converter 2, and the data collection and remote transmission device 3 is installed above the signal converter 2. One end of the data collection and remote transmission device 3 is electrically connected to the output end of the signal converter 2, and the other end is connected to the output end of the signal converter 2. The upper computer 19 is electrically connected.

[0028] It should be noted that the electromagnetic induction device 1 is composed o...

Embodiment 3

[0030] In order to solve the current problem that it is impossible to monitor the wear of oil well tubing rods online in real time, this embodiment provides such figure 1 The online monitoring device for the degree of wear of the tubing rod includes an electromagnetic induction device 1, a signal converter 2, a data collection and remote transmission device 3, and a host computer 19. The electromagnetic induction device 1 is installed below the signal converter 2, and It is electrically connected to the input end of the signal converter 2, and the data collection and remote transmission device 3 is installed above the signal converter 2. One end of the data collection and remote transmission device 3 is electrically connected to the output end of the signal converter 2, and the other end is connected to the output end of the signal converter 2. The upper computer 19 is electrically connected.

[0031] The data collection and remote transmission device 3 is composed of a data c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com