In-situ digital three-dimensional borehole wall strain gauge based on complete temperature compensation technology

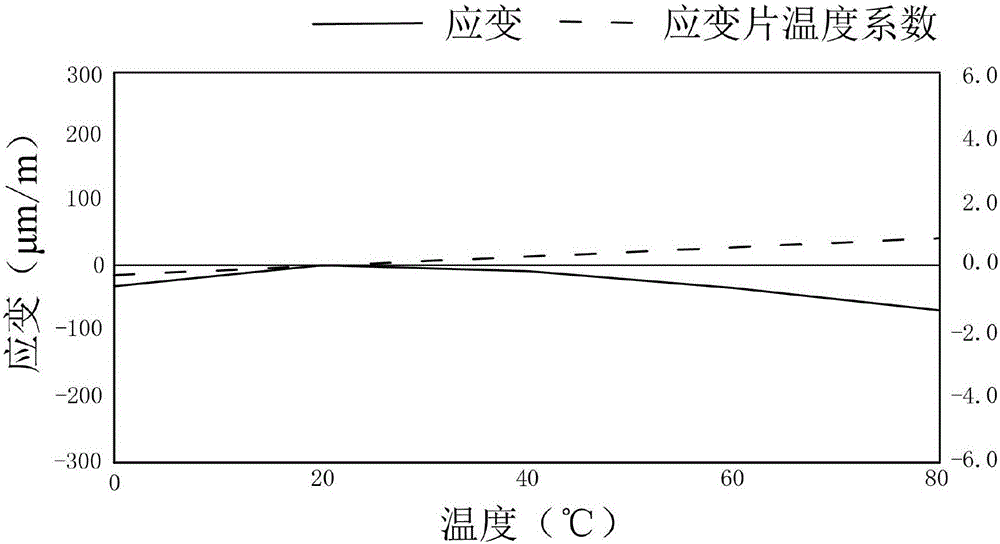

A technology of temperature compensation and strain gage, applied in the direction of electric/magnetic solid deformation measurement, measuring devices, instruments, etc., can solve the problems of inability to realize full compensation of temperature influence, inability to achieve long-term measurement, and large temperature change range, etc., to achieve integration The long-term monitoring function of chemicalization and disturbance stress, the effect of increasing the acquisition range and measurement stability, and eliminating the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0042] The invention provides an in-situ digitized three-dimensional hole wall strain gauge based on a complete temperature compensation technology.

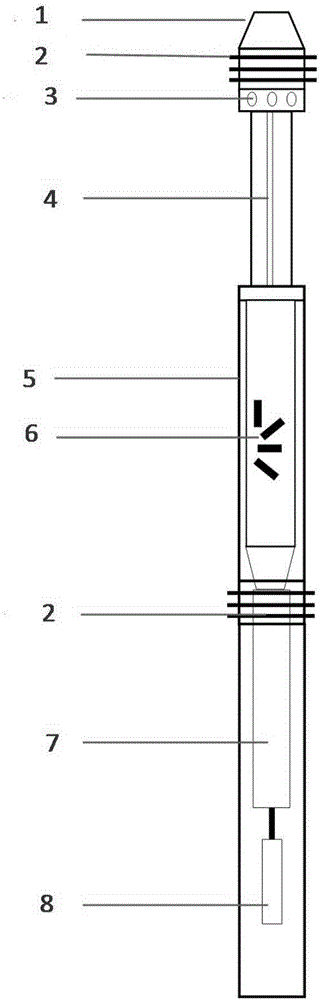

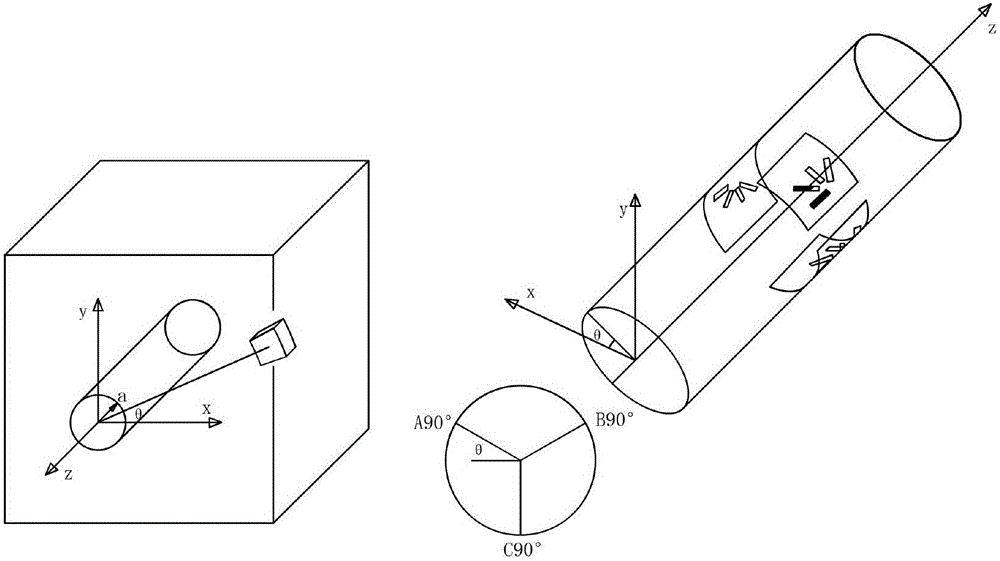

[0043] The strain gauge includes a glue-injected hollow cladding strain gauge skeleton, a high-precision self-compensating strain sensor, a double ground wire and a complete temperature compensation measurement circuit, and a local digital acquisition integrated circuit board; a high-precision self-compensating strain sensor, a double ground wire and a complete The temperature compensation measurement circuit and the local digital acquisition integrated circuit board are set in the skeleton of the glue-injected hollow-body strain gauge, and the strain gauge uses a double ground loop to connect the local dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com