Liner for solar heat collective header

A solar heat collection and liner technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of low welding strength, complicated welding process, and easy cracking of welding places, so as to save costs, The effect of large contact area and increased pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail:

[0020] The invention is an inner container of a solar heat collecting header, which has the characteristics of high pressure bearing, no leakage, low cost and convenient installation.

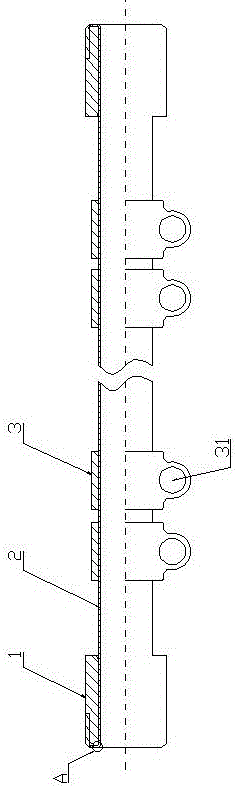

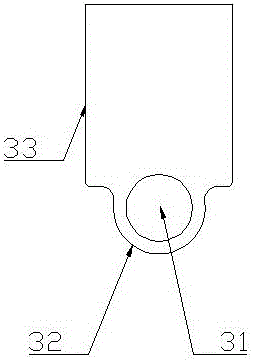

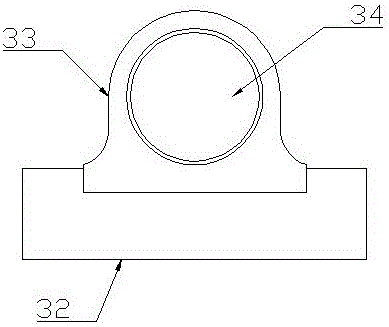

[0021] like figure 1 As shown, the main components of the heat collecting header liner of the present invention include a copper liner, a wire head and a heat exchange module, wherein the copper tube liner is used to circulate the heat exchange medium, and transfer the heat of the heat collection tube to the heated medium; For the convenience of connection and installation, the two ends of the copper tube liner are fixed with wire heads for connection. In order to ensure the sealing and the convenience of connection, the two ends of the copper tube liner have flanges (such Figure 5 shown), and the end faces at both ends are flat, the wire head sets are fixed at both ends of the copper tube line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com