Coring drilling tool based on hydraulic clamping coring

A core drilling tool and core technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling, engine sealing, etc., can solve the problems of low construction efficiency, affecting the stability of the hole wall, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

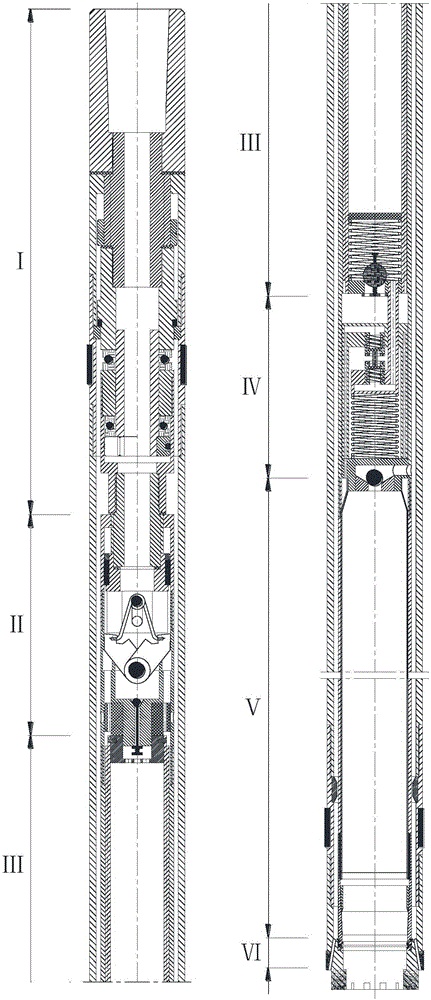

[0049] In this embodiment, the core drilling tool based on hydraulic pressure to get the core, such as figure 1 As shown, it includes force transmission transfer mechanism Ⅰ, diversion limit mechanism Ⅱ, pressure storage mechanism Ⅲ, lifting and injection pressure mechanism Ⅳ, hydraulic clamping mechanism Ⅴ, side spray drill bit transfer mechanism Ⅵ, outer pipe assembly and seal system.

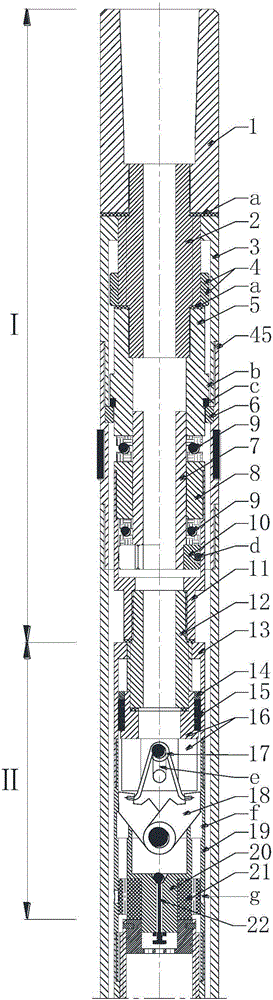

[0050] Such as figure 2 As shown, the force transmission transfer mechanism I includes a drill pipe handle 1, a power shaft 2, a different movement handle 3, a double limit nut 4, a conversion handle 5, a force transmission ring 6, a sliding sleeve seat 7, a sliding sleeve 8, and two thrusts up and down. Bearing 9, sealing nut 10 and mandrel adapter 11; the upper end of the power shaft 2 is threadedly connected with the drill pipe adapter 1, and the lower end is threadedly connected with the transfer adapter 5, with a through hole in the axial direction, and the shaft body is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com