Fiber-broken stone synchronous-sealing pavement maintenance method

A fiber and pavement technology, applied in the field of fiber gravel synchronous seal road maintenance and preventive maintenance treatment, can solve the problems of white pavement, poor anti-skid performance, easy to fall off, etc., to prevent water seepage, prolong service life, and improve adhesion. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The fiber gravel synchronous sealing layer pavement maintenance method of the present invention comprises the following steps:

[0015] 1) Spray the first layer of modified emulsified asphalt

[0016] Spray the modified emulsified asphalt that meets the technical requirements evenly on the original road surface, and the spraying amount is generally converted into pure asphalt to be 0.15kg / m 2 ~0.25kg / m 2 Control, the performance index of modified emulsified asphalt is shown in Table 1 below.

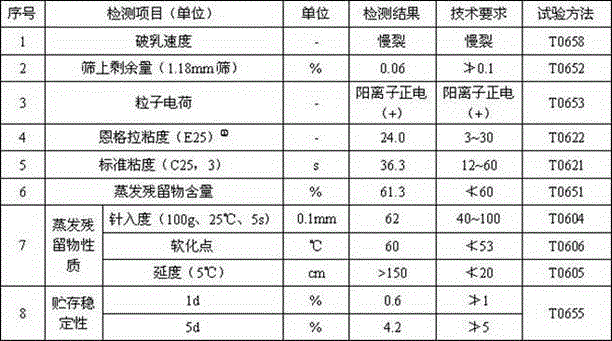

[0017] Table 1 Test results of modified asphalt

[0018]

[0019] 2) Simultaneously spread fiber and gravel aggregate

[0020] While spraying the first layer of modified emulsified asphalt, simultaneously spread fiber and crushed stone aggregate, the full coverage rate of the aggregate should be close to 100%; the fiber used in this step is ordinary glass fiber, with a length of 50-60mm, which should meet The requirements shown in Table 2; the aggregate specifications are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com