A high-temperature film strain gauge and its manufacturing method

A manufacturing method and technology of strain gages, which are applied in electric/magnetic solid deformation measurement, ion implantation plating, electromagnetic measurement devices, etc., can solve problems such as difficulty in use, reduce flexibility and error of strain gages, and achieve high wear resistance. , The effect of improving antioxidant protection performance and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

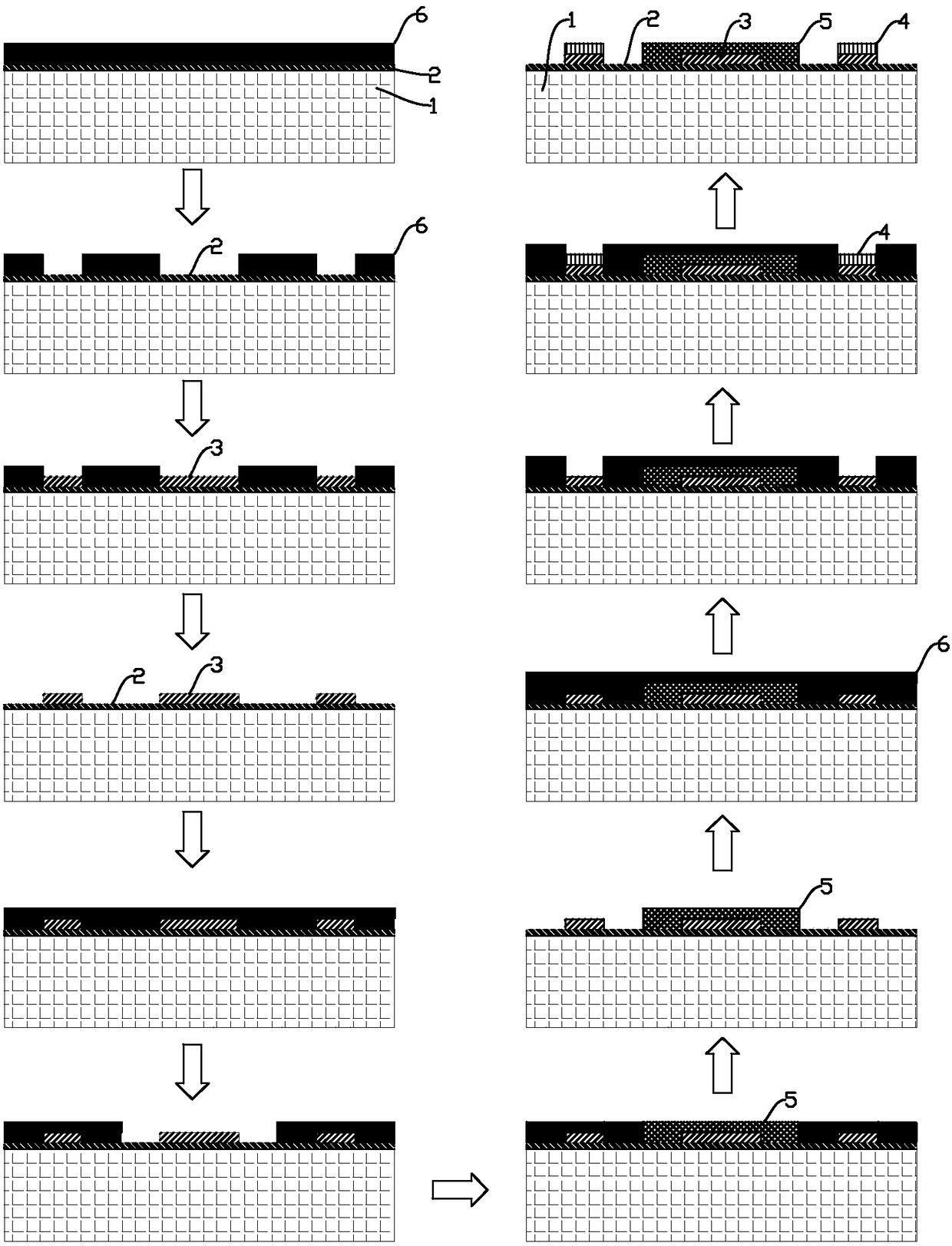

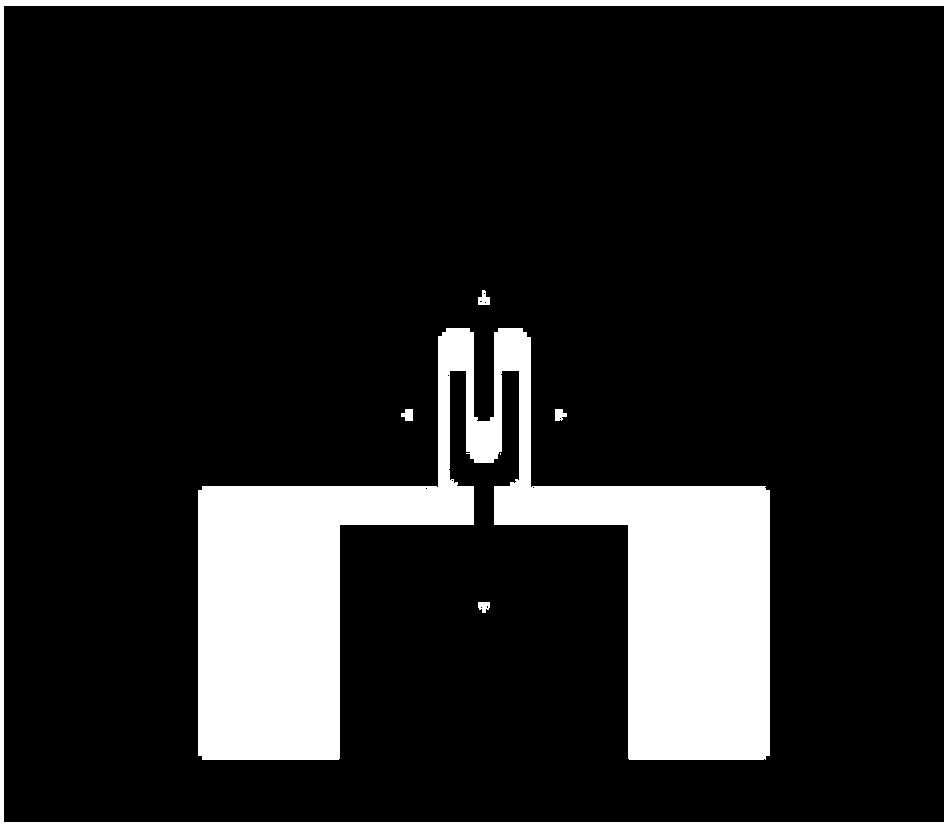

[0024] Such as figure 1 and figure 2 As shown, a high temperature thin film strain gauge, including copper alloy substrate 1, SiO 2 Insulation film 2, strain gauge sensitive gate film 3, pad shielding film 4 and sensitive gate shielding film 5, the area of the strain gauge sensitive gate 3 is covered with the sensitive gate shielding film 5, the area other than the strain gauge sensitive gate 3 Covered with a pad shielding film 4, the strain gauge sensitive gate 3 is a NiCr alloy sensitive gate, and the sensitive gate shielding film 5 is SiO x N y film, the pad shielding film 4 is an ITO film.

[0025] Such as figure 1 Shown, a kind of manufacture method of high-temperature film strain gauge comprises the following steps:

[0026] Step 1: Pretreatment of the substrate Firstly, a 20mm×18mm×1mm copper alloy substrate is selected as the substrate according to the size of the strain gauge sensitive grid. Then, the surface of the copper alloy substrate is cleaned with acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com