A method of relay hoisting gas cooler

A gas cooler and hoisting technology, which is applied in hoisting devices, portable lifting devices, etc., can solve the problems of inability to directly hoist in place, heavy weight, and large volume, and meet the requirements of less mechanical use, strong practicability, and structural requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred modes of the present invention will be described in further detail below in conjunction with the examples.

[0023] A method for relay hoisting a gas cooler, comprising the following steps:

[0024] S1. Construction preparation

[0025] First use the three-dimensional technology to simulate the hoisting space to obtain the position of the steel structure avoidance components, then dynamically adjust according to the three-dimensional simulation, prepare the corresponding wire ropes, pulley blocks and hoists, and finally clean the ground of the site where the hoisting will be carried out, and remove the steel structures that need to be avoided. The structure is demolished.

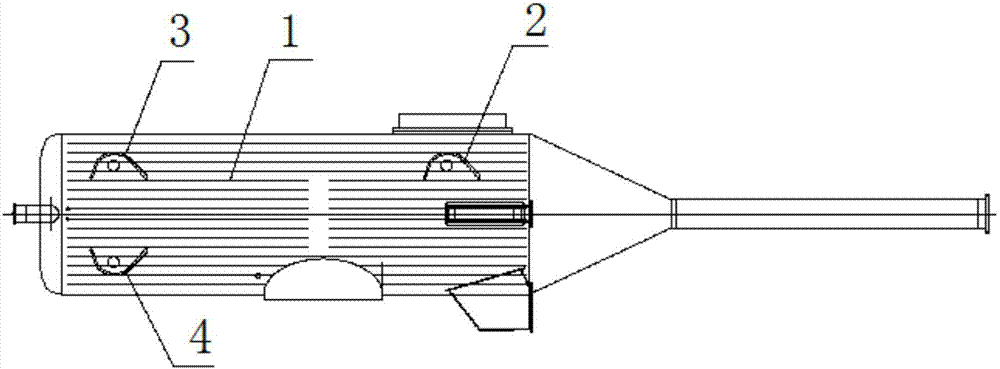

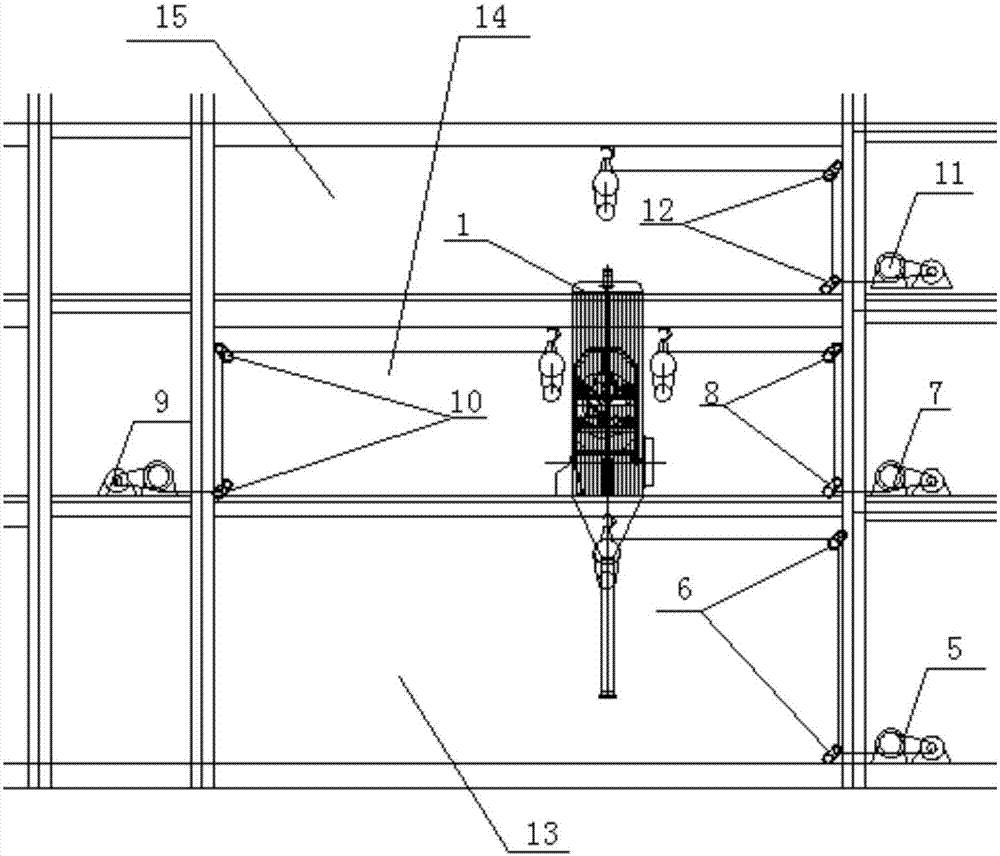

[0026] S2. Setting of hoisting point, winch and pulley block

[0027] Such as figure 1 As shown, first set the first lifting lug 2 and the second lifting lug 3 on the gas cooler 1 to be hoisted for the gas cooler 1 to move horizontally, and the horizontal distance between the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com