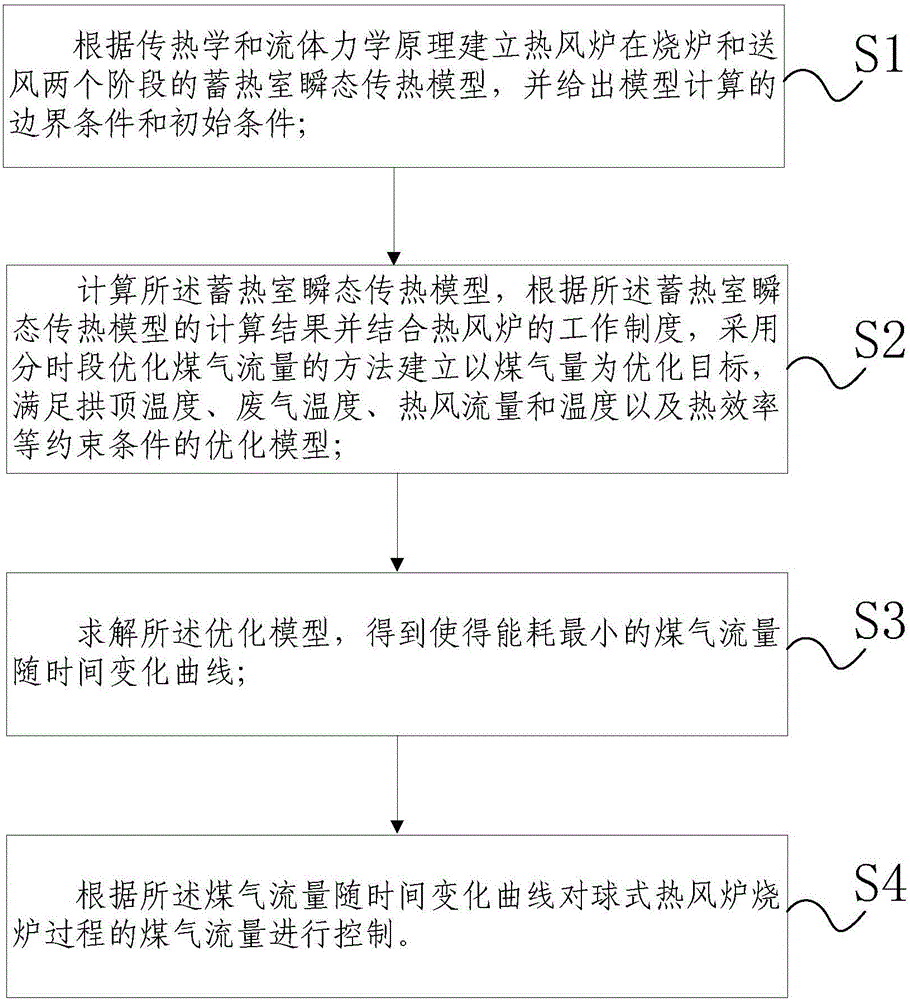

Method and system for ball type hot blast furnace sintering process modeling and energy consumption optimization

An optimization method and technology of hot blast stove, applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems of gas waste, inability to change the furnace status in time, and furnace instability, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

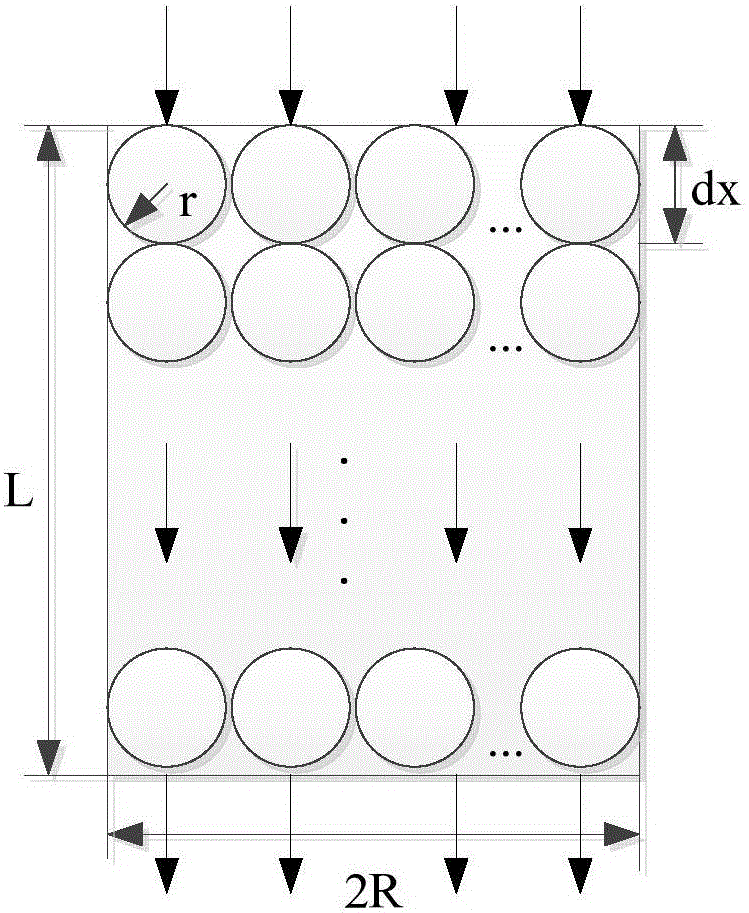

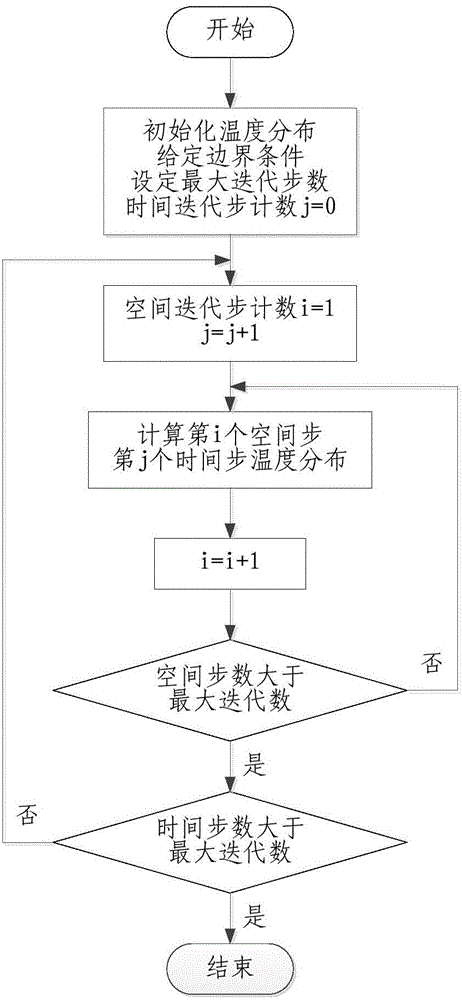

[0109] This embodiment is in a steel factory 2650m 3 The test was carried out on the hot blast stove of the blast furnace. Utilize the transient heat transfer model and energy consumption optimization model established by the present invention, and obtain the optimal gas flow given curve according to the steps of model calculation. in particular:

[0110] First, according to the process parameters and detected data of the hot blast stove, including the radius of the regenerator of the hot blast stove, the length from the top to the bottom of the regenerator, the radius and physical parameters of the heat storage ball, the vault temperature of the hot blast stove, and the gas flow rate, Determine the parameters of the established transient model. Then, the firing time is divided into 4 sections, each period is 30 minutes, and the gas flow series is divided into 20 levels. Finally, the iterative calculation is carried out according to the calculation steps of the energy consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com