Divided-period and multi-stage matching and optimizing method for operation parameters in furnace burning process of blast furnace and hot blast furnace

A technology of operating parameters and hot blast stoves, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the inability to establish accurate mathematical models, calculate the best air-fuel ratio and operating parameters, and achieve energy-saving and cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

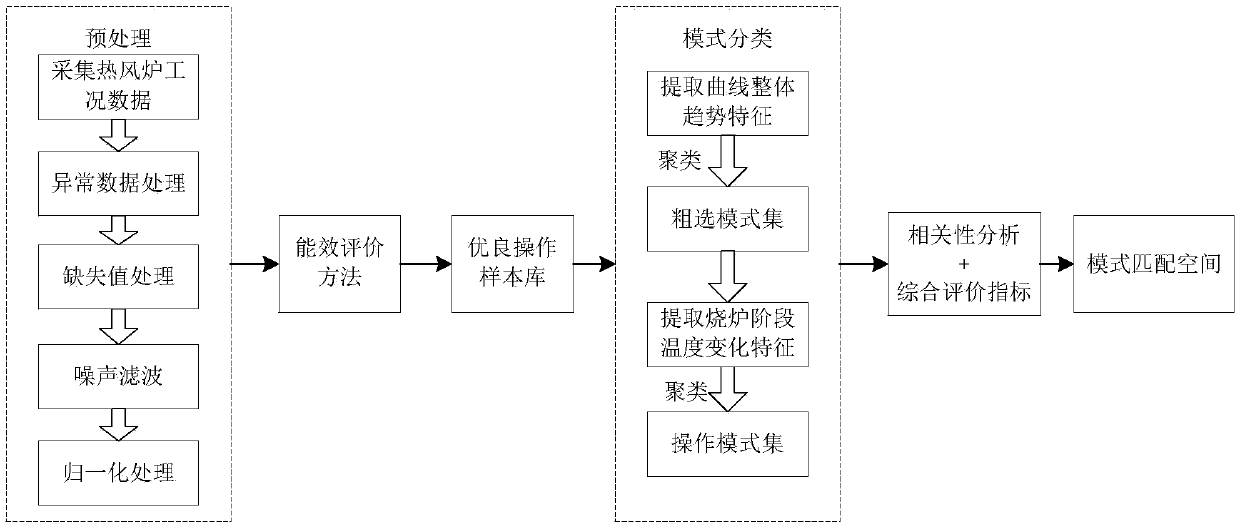

[0046] figure 2 It is the firing process of the blast furnace hot blast stove. The blast furnace gas is processed by dry dust removal, etc., and is transported to the top of the hot blast stove and burned with the preheated air according to the set air-fuel ratio. The heat exchange stores heat in the regenerator in the furnace to achieve the air supply target. Therefore, whether the setting of air-fuel ratio is reasonable or not is not only the key factor to determine the combustion efficiency and heat storage efficiency of the furnace, but also the direct influencing factor of the change of vault temperature and flue gas temperature and its change rate.

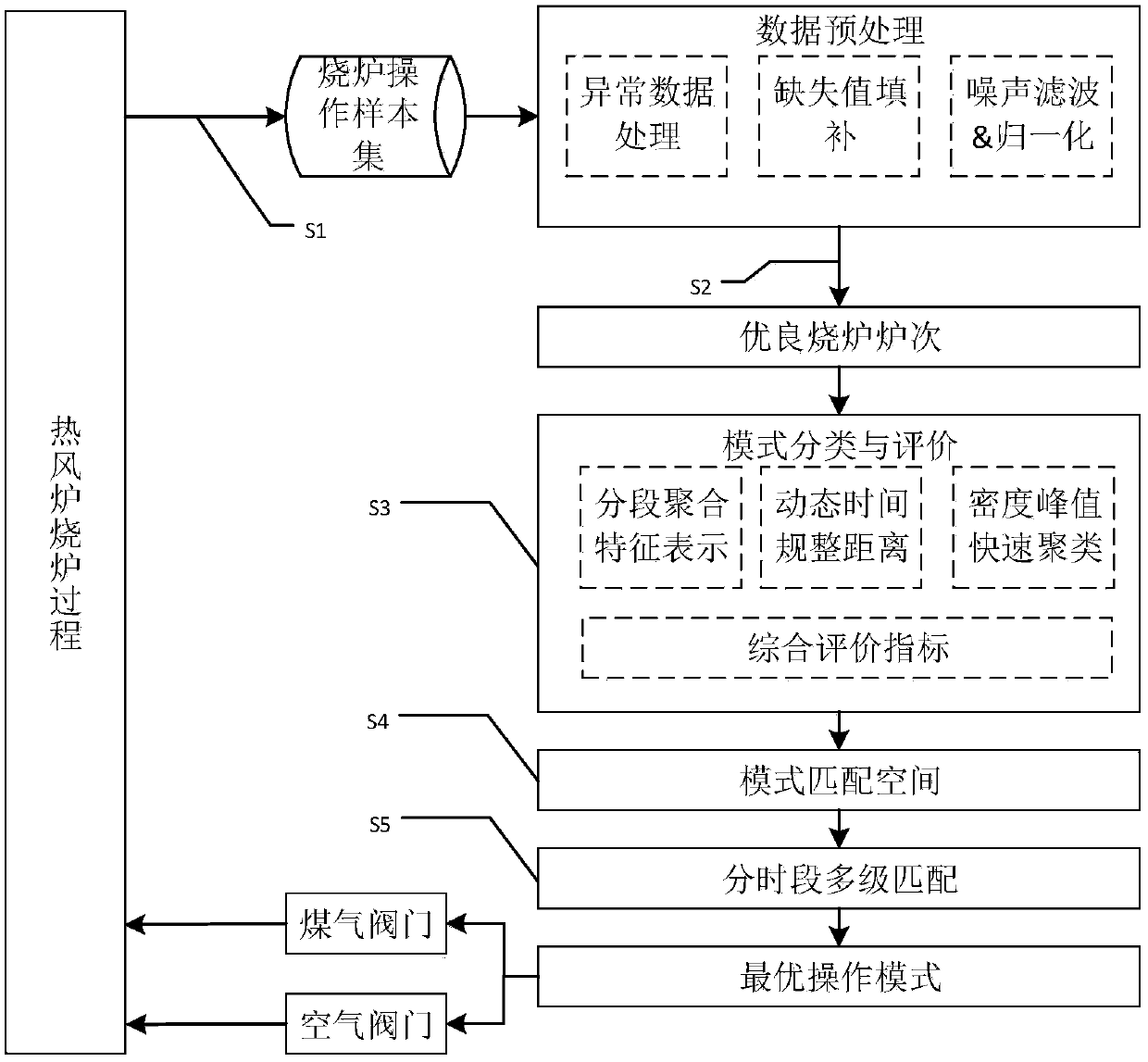

[0047] The present invention proposes such as figure 1 The shown method for optimizing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com