Novel production technology and equipment for tableware bag

A technology of production equipment and production technology, which is applied in the field of production technology and production equipment of new tableware bags, can solve the problems of high labor intensity, low production efficiency of manual production, and hidden dangers of sanitation, so as to save production materials and reduce labor intensity of personnel , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

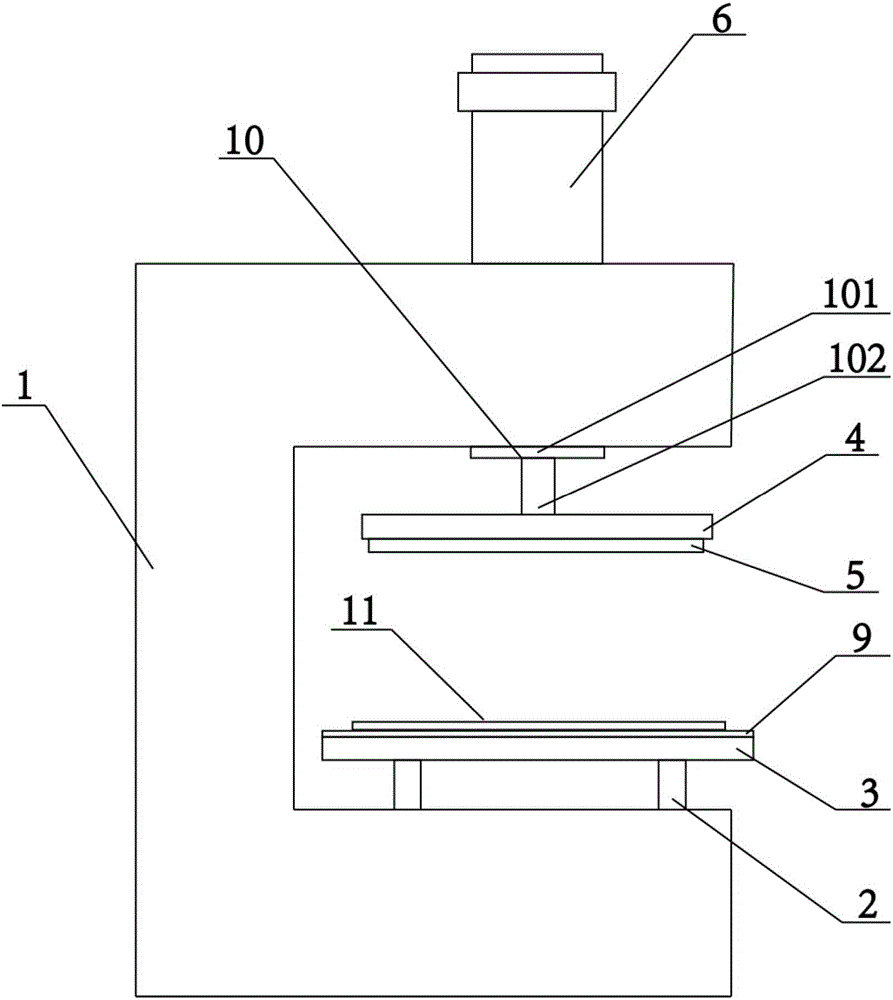

Embodiment 1

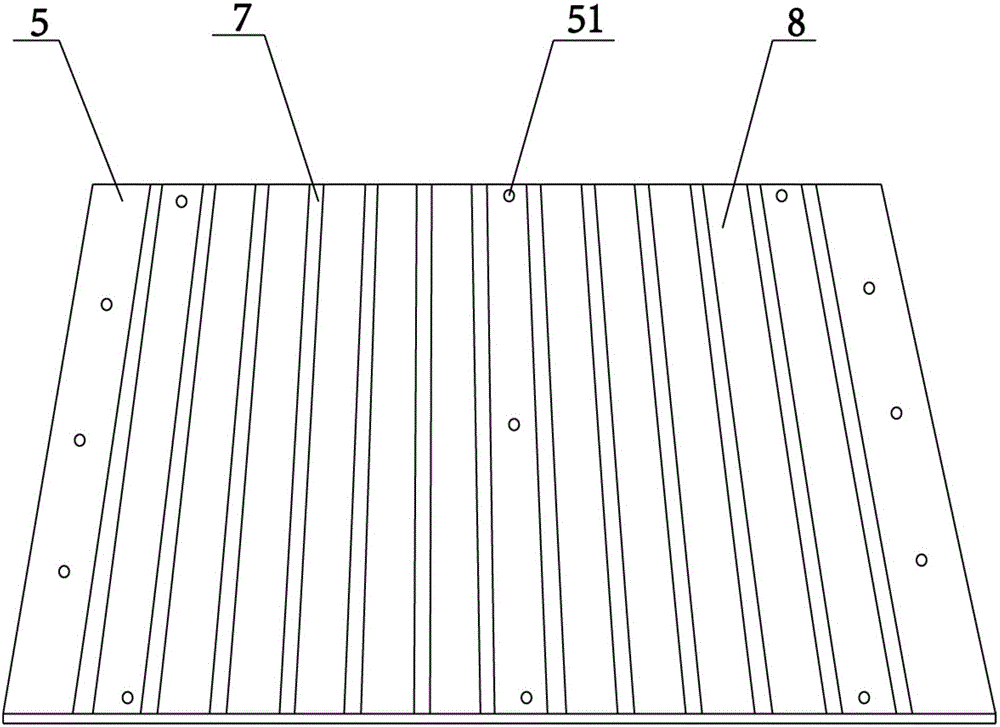

[0050] The cutlery bag 11 in the present embodiment 1 is specifically a chopsticks cover, with figure 2 It is a structural schematic diagram of the heat sealing plate 5 and the protrusion 7 corresponding to the chopsticks cover.

[0051] The shape of the chopsticks cover is rectangular, please refer to the attached Figure 6 And attached Figure 7 . The protrusion 7 is made of copper, and a plurality of protrusions 7 are vertically arranged on the heat-sealing plate 5 and distributed evenly in parallel. A processing area 8 is formed. The chopsticks cover is fixed on the base plate 3 through three-point positioning. During processing, the protrusion 7 seals the sealing part 111 of the chopsticks cover, and the main body of the chopsticks cover other than the sealing part 111 is located in the processing area 8 . In this embodiment, multiple chopstick covers can be processed at one time. The positions of the mounting holes 51 are all located around the heat sealing plate ...

Embodiment 2

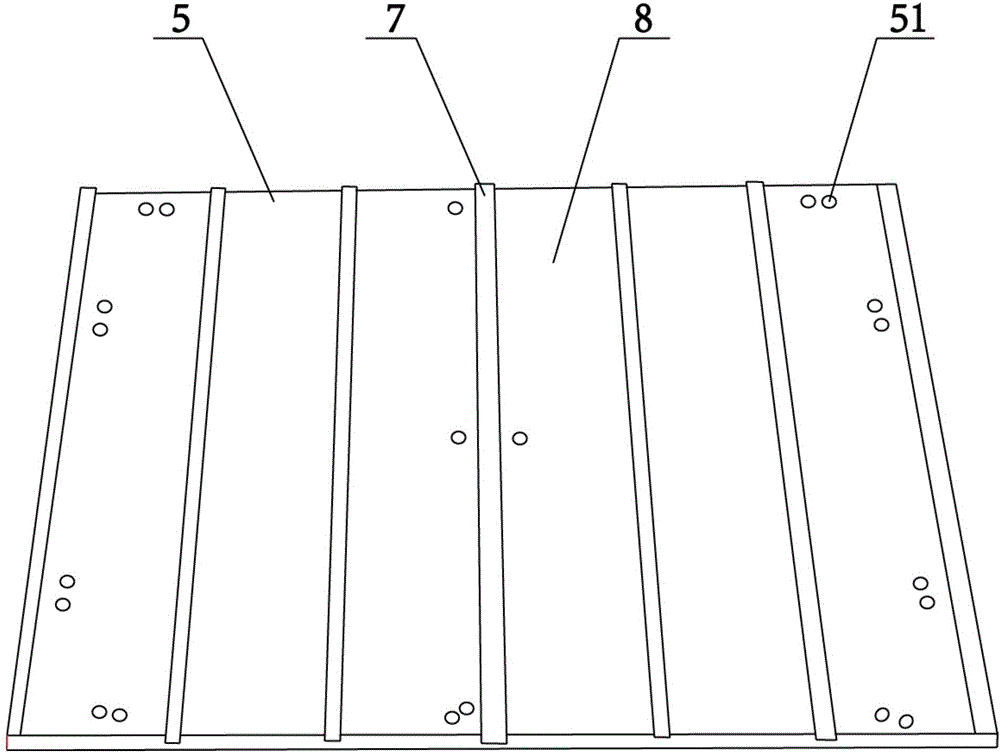

[0053] The tableware bag 11 in the present embodiment 2 is specifically a tableware bag, with image 3 It is a structural schematic diagram of the heat sealing plate 5 and the protrusion 7 corresponding to the cutlery bag.

[0054] The shape of the cutlery bag is rectangular, so the plurality of protrusions 7 are distributed parallel and evenly on the heat sealing plate 5. The width of the protrusions 7 is consistent with the width of the sealing part 111 of the cutlery bag, and a gap is formed between two adjacent protrusions 7. The processing area 8, wherein the protrusion 7 is made of iron sheet.

[0055] The cutlery bag is fixed on the base plate 3 by three-point positioning. During processing, the protrusion 7 performs edge sealing and heat sealing on the sealing portion 111 of the cutlery bag, and the main body of the cutlery bag other than the sealing portion 111 is located in the processing area 8 . In this embodiment, a plurality of cutlery bags can be processed at ...

Embodiment 3

[0057] The cutlery bag 11 in the present embodiment 3 is specifically a toothpick cover, with Figure 4 It is a structural schematic diagram of the heat sealing plate 5 and the protrusion 7 corresponding to the toothpick cover.

[0058] The shape of the toothpick cover is rectangular, and the size of the toothpick cover is smaller than that of the cutlery bag or the chopsticks cover, so the arrangement of the protrusions 7 on the corresponding heat sealing plate 5 is different from that of the cutlery bag or the chopsticks cover. In this embodiment, a plurality of longitudinal protrusions 71 are evenly distributed along the length direction of the heat-sealing plate 5, and a transverse protrusion 72 is arranged in the middle of the longitudinal protrusions 71, and the transverse protrusion 72 is connected with all the longitudinal protrusions 71. The protrusions 72 and the longitudinal protrusions 71 protrude from the heat sealing plate 5 at the same height. The width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com