Method for hot-charging for roll skin of loop roll

A technology of looper rolls and roll skins, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problem of uneven butt joint inclination between the roll skin and the roll shaft, inaccurate control of the heating temperature, and inaccurate positioning of the sleeve joint of the roll skin and other problems, to achieve the effect of good thermal installation, precise temperature control, and installation alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: a kind of method for hot loading of looper roll skin, comprises the following steps:

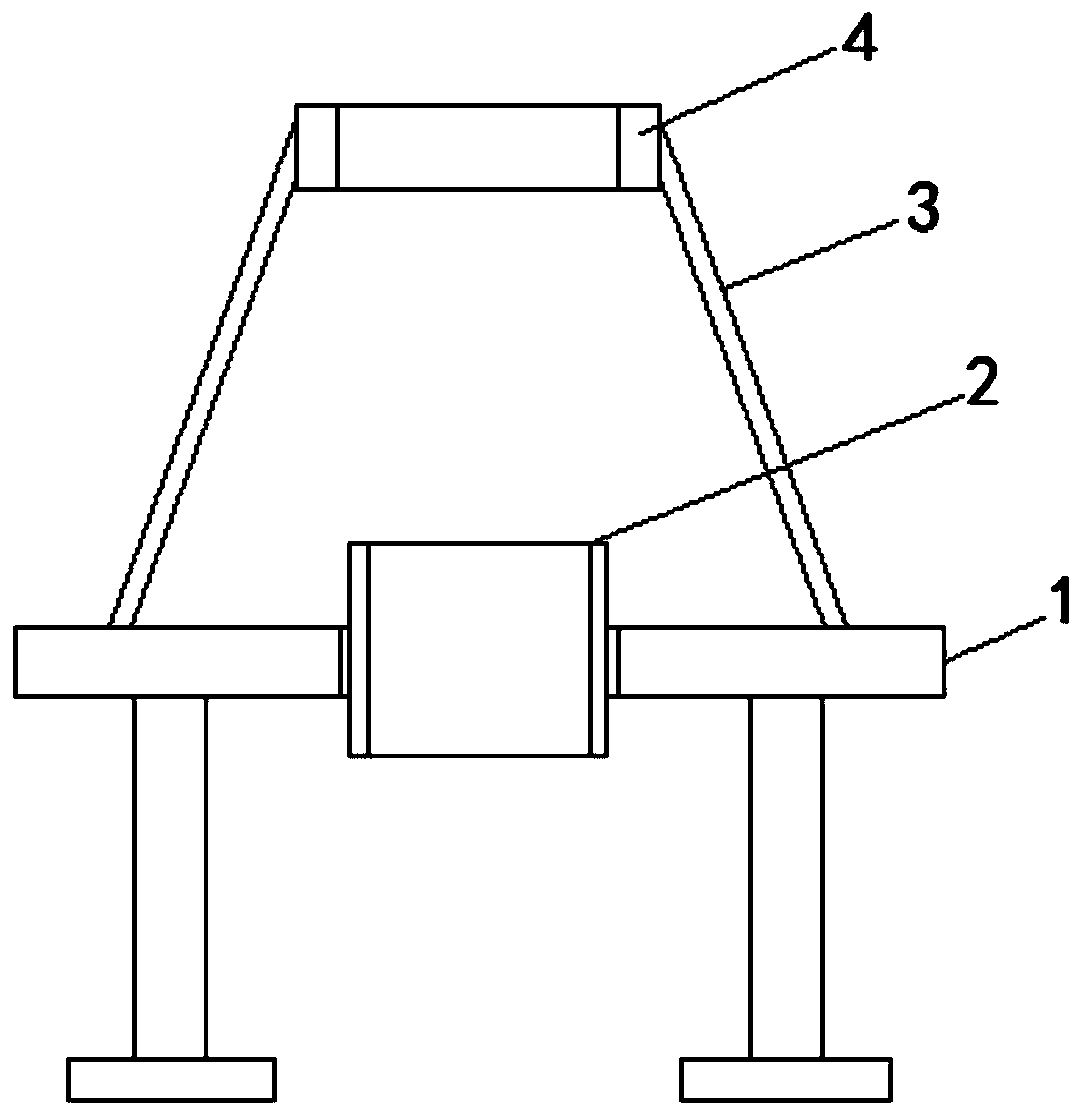

[0028] 1) Calibrate the table surface of the tooling 1 horizontally, and the roller skin passes through the limit ring 4 on the support rod 3, and is socketed on the outside of the positioning ring 2 to fix the roller skin;

[0029] 2) Use 5 crawler heaters to wrap the roller skin. The crawler heater is connected to the temperature controller. At the same time, place a thermocouple at the place where each heater contacts the roller skin. wrapped up;

[0030] 3) Set the parameters of the temperature controller. The heating process is to raise the temperature to 450°C in 30 minutes and keep it warm for 2 hours;

[0031] 4) Use the crane to lift the roller shaft, and after adjustment, ensure that the roller shaft is placed vertically;

[0032] 5) Use the inner diameter gauge to detect the inner diameter of the upper end and lower end of the roller skin to ensure that the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com