Composite beneficiation inhibitor used for copper-arsenic separating flotation

An arsenic separation and inhibitor technology, applied in flotation, solid separation and other directions, can solve the problems of corroding equipment, polluting the environment, affecting the quality of copper smelting products, etc., and achieving the effects of low cost, good separation effect and easy-to-obtain components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

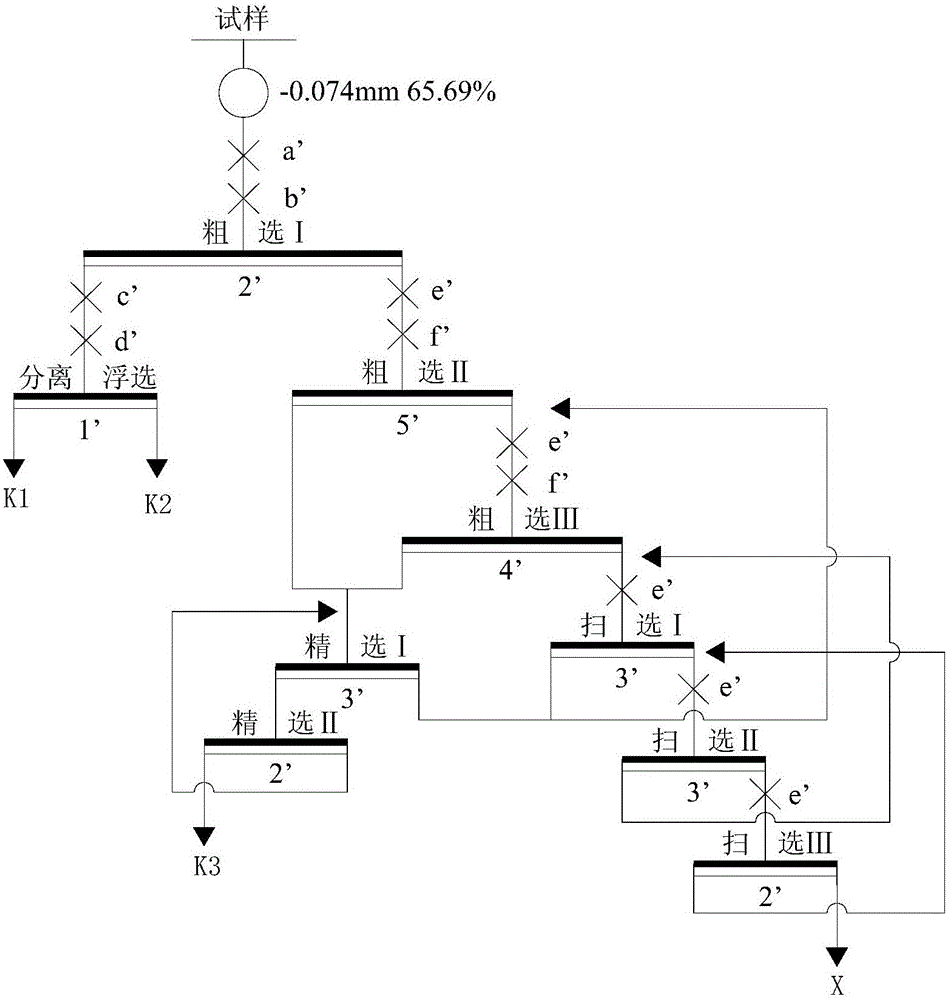

[0036] Such as figure 1 As shown, weigh 1Kg of crushed raw ore (containing 0.62% copper, 0.032% arsenic) and put it into a ball mill for grinding until the grinding fineness is -0.074mm, accounting for 65%. The grinding medium is clear water. The ore concentration is 50%. Put the ground pulp into the 3L flotation tank, calculate according to the dry weight of each ton of raw ore, add lime a'1800g / t, lipid collector b'10g / t in sequence, and carry out the first copper Rough selection; then sequentially add butyl ammonium black drug e'10g / t, terpineol oil f'5g / t, stir and adjust the slurry, then carry out the second copper rough selection; then add butyl ammonium black drug e'5g / t in sequence , terpineol oil f'5g / t, after stirring and pulping, carry out the third copper roughing. Add sodium sulfide c'200g / t and compound beneficiation inhibitor d'200g / t to the copper concentrate obtained in the first copper roughing operation in sequence, and then carry out separation and flotat...

Embodiment 2

[0042] Such as figure 2 As shown, weigh 1Kg of crushed raw ore (containing 0.34% copper, 0.019% arsenic) and put it into a ball mill for grinding until the grinding fineness is -0.074mm, accounting for 65%. The grinding medium is clear water. The ore concentration is 50%. Put the ground pulp into the 3L flotation tank, calculate according to the dry weight of each ton of raw ore, add lime a'1800g / t, lipid collector b'10g / t in sequence, and carry out the first copper Rough selection; then sequentially add butyl ammonium black drug e'10g / t, terpineol oil f'5g / t, stir and adjust the slurry, then carry out the second copper rough selection; then add butyl ammonium black drug e'5g / t in sequence , terpineol oil f'5g / t, after stirring and pulping, carry out the third copper roughing. Add ammonium butyl ammonium black drug e'5g / t, stir and slurry for the first copper sweep; then add ammonium butyl ammonium black drug e'5g / t, stir and slurry for the second copper scavenging; finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com