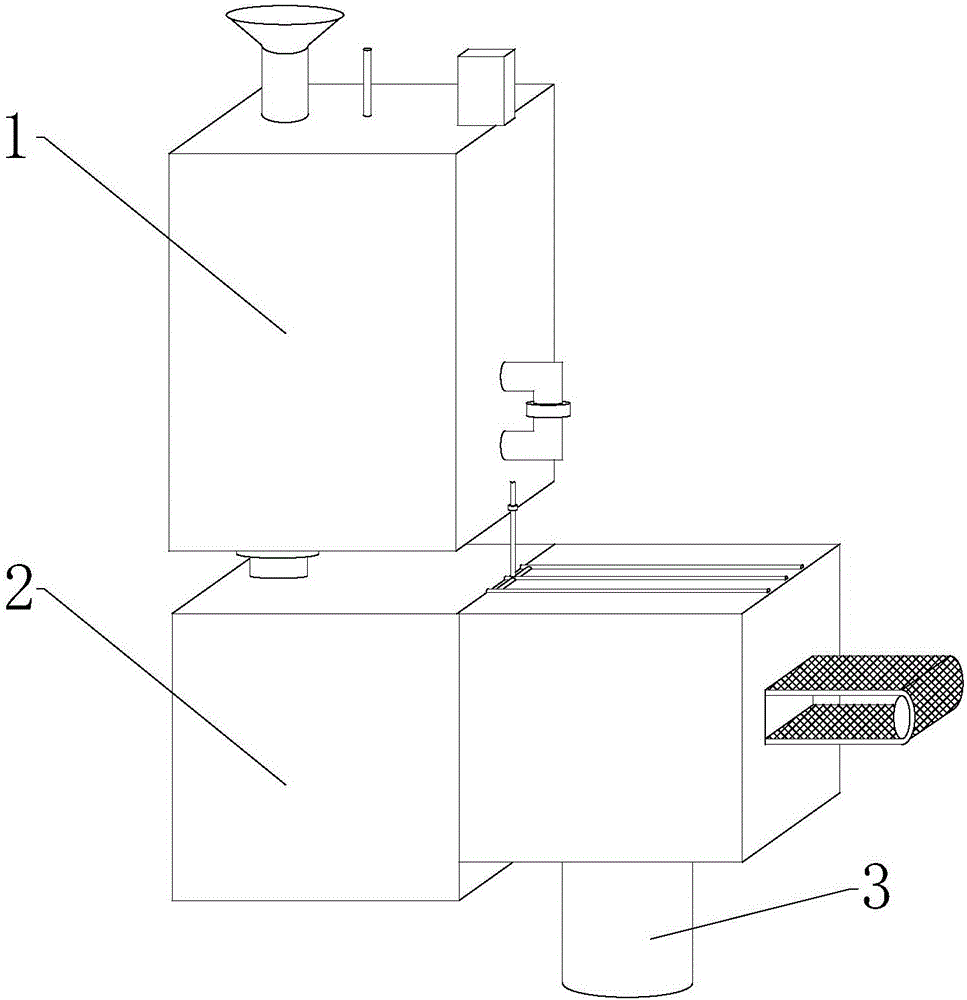

Screening and washing equipment before processing of vegetable seeds

A rapeseed and pre-screening technology, which is applied in the field of machinery and equipment, can solve the problems of reducing the quality and quality of rapeseed oil, insufficient cleaning of rapeseed, and affecting people's health, and achieves easy operation, improved screening and washing effect, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

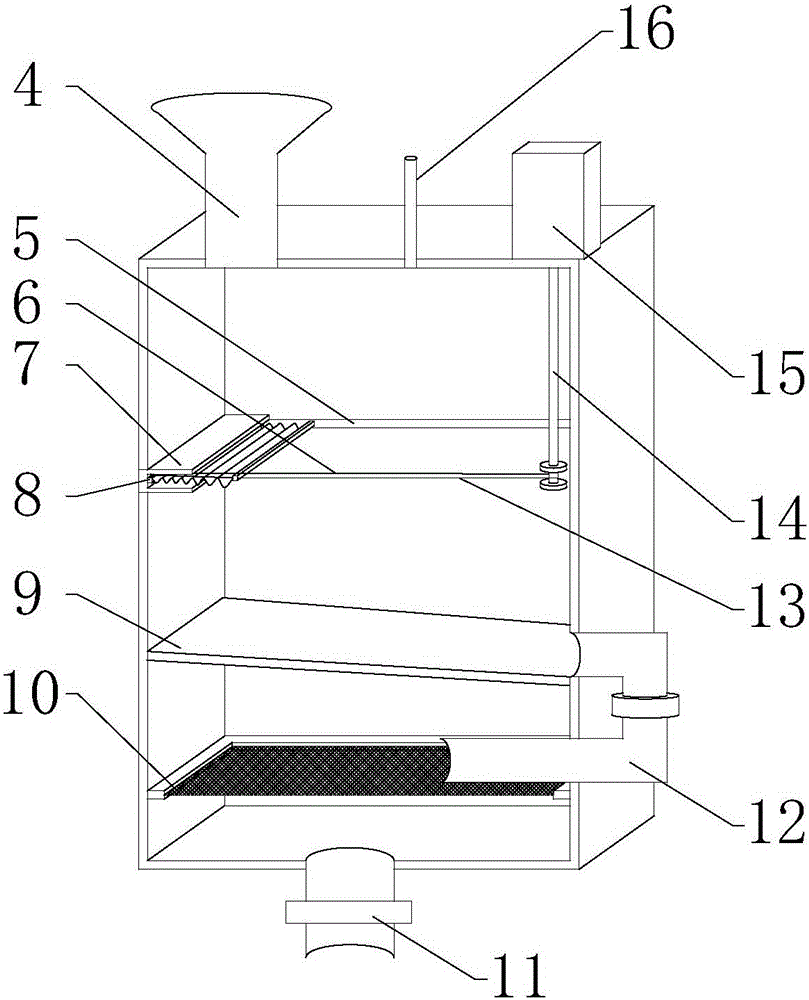

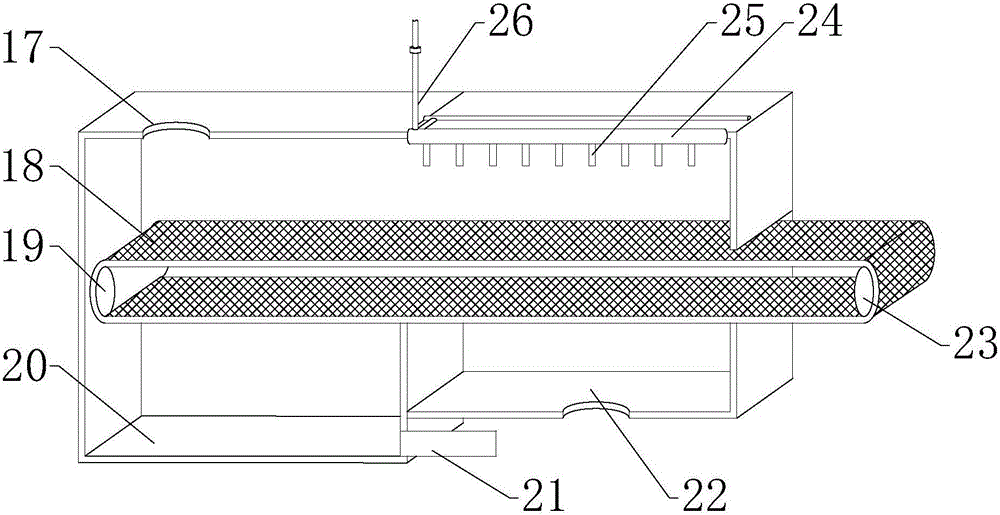

[0024] The specific embodiment: the workman pours the rapeseed into the middle baffle 9 from the trumpet-type rapeseed inlet pipe 4, and the worker adds water to the middle baffle 9 through the water inlet pipe 16, and the middle baffle 9 top is filled up, and after a while After 10 minutes, the rapeseed on the intermediate baffle 9 is soaked through soaking, and the impurities in the rapeseed, moldy rapeseed and immature rapeseed will float on the upper part in the water, and the worker opens the motor 15, and the motor 15 starts working. Then drive the fixed rod 2 30 to move to the right by the pull rope 13, when the fixed rod 2 30 moves to the far right, the filter cloth 29 is fully unfolded, and the worker opens the on-off valve of the connecting pipe 12, rapeseed and water will pass through the connecting pipe 12 Entering the filter assembly 10, during this process, the expanded filter cloth 29 will block sundries such as mildewed rapeseed and immature rapeseed, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com