Coal feeder conveying belt pulverized coal scraping device

A technology of scraping device and conveyor belt, which is applied in the direction of conveyors, cleaning devices, conveyor objects, etc., can solve the problems of single cleaning method, failure to achieve cleaning effect, and affect the working environment on site, so as to achieve simple and easy operation , Guarantee the effect of use and improve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

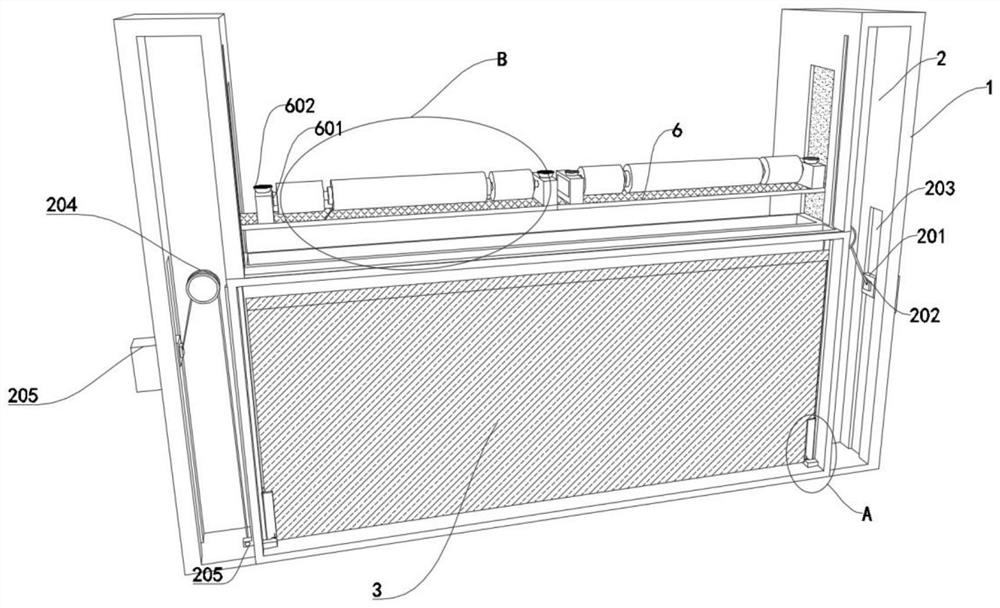

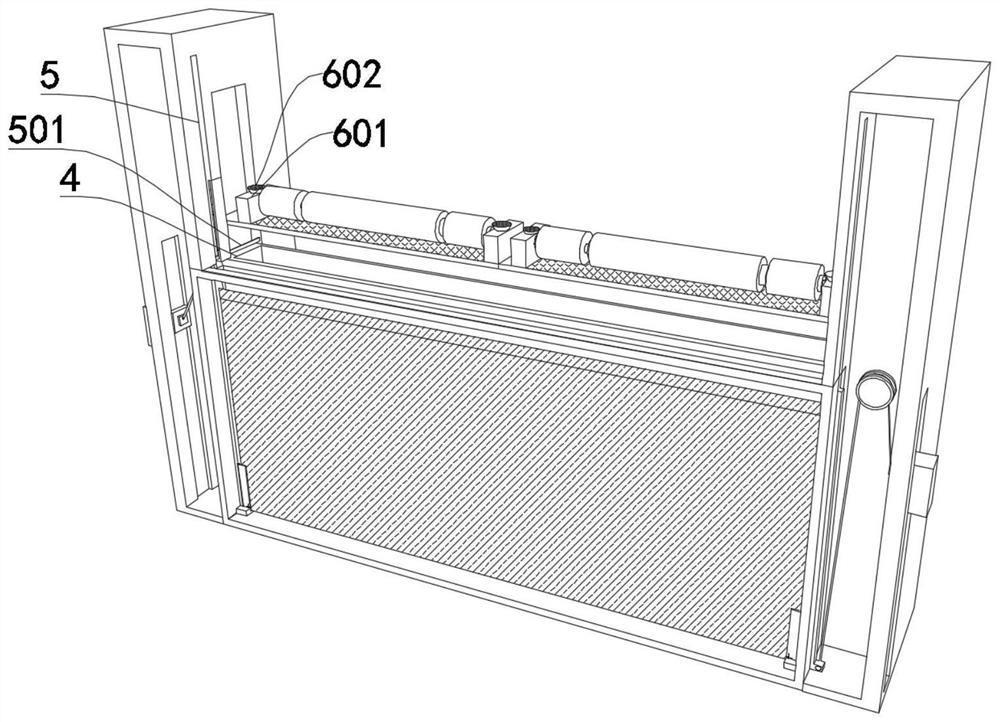

[0028] Refer figure 1 , figure 2 A coal-free device for the coal discharge device, including the apparatus main body 1, and the outer side wall of the apparatus main body 1 are provided with a binder cartridge 4, and the binder 4 is located at the front of the blade 3, and the internal setting of the device main body 1. There is a transmission rising mechanism, and the transmission rising mechanism includes a transmission bond 2 opening in the inner side wall of the apparatus main body 1, and the inner side wall of the transmission bin 2 is opened, and the inner side wall sliding of the sliding groove 203 has a belt 201, with a unit 201 The outer wall is fixedly connected to the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com