Cleaning and drying device for processing filter membrane of water purifier

A drying device and water purifier technology, applied in membrane technology, filtration separation, semi-permeable membrane separation, etc., can solve problems such as clogging and the influence of water flow export, and achieve the goal of increasing the export rate, increasing the movement rate, and reducing the deposition of impurities speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

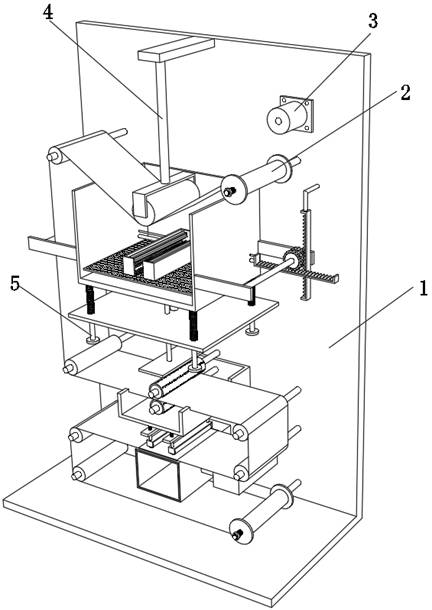

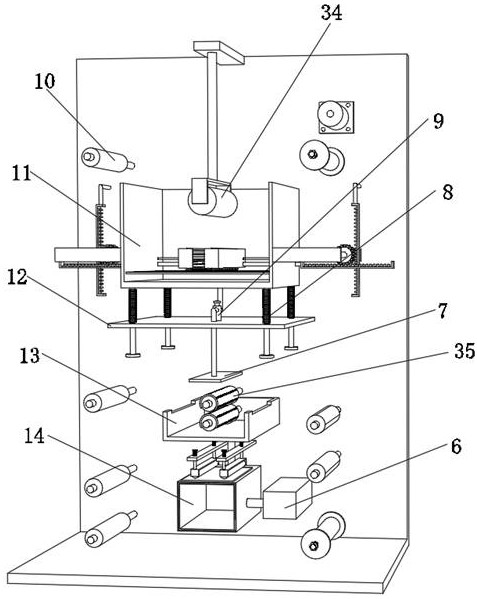

[0036] A kind of washing and drying device for the processing of filter membrane of water purifier, such as Figure 1-5As shown, it includes a mounting frame 1, a filter membrane 2 and a guide conveying mechanism. The inner wall of the top of the mounting frame 1 is fixed with a fixed frame 4 by bolts, and the inner walls on both sides of the fixed frame 4 are rotatably connected to the same adjustment roller 34. The inner wall of one side of the mounting frame 1 is fixed with a base 12 by bolts, and the outer wall of the top of the base 12 is slidably connected with two or more guide columns 5, and the outer walls of the top of the two or more guide columns 5 are fixed with the same water tank 11 by bolts. The outer wall of the guide column 5 is slidably connected to the spring one 8, and the two ends of the spring one 8 are respectively clamped on the outer wall of the top of the base 12 and the outer wall of the bottom of the water tank 11, and the inner wall of the water ta...

Embodiment 2

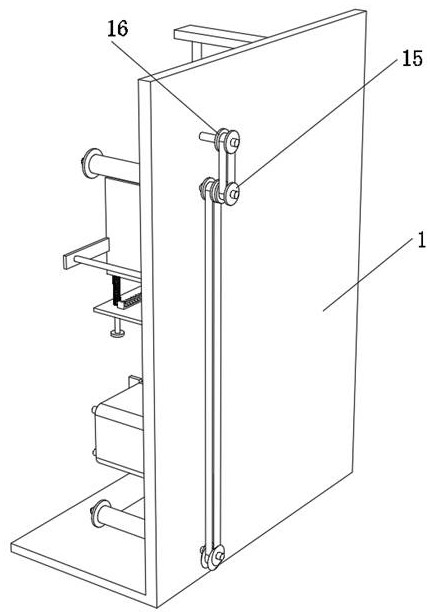

[0043] A kind of washing and drying device for the processing of filter membrane of water purifier, such as figure 1 , Figure 6 As shown, in order to improve the effect of drying the filter membrane 2; the present embodiment makes the following additions on the basis of embodiment 1: the inner wall of one side of the mounting frame 1 is fixed with two horizontal plates 25 by bolts, and the horizontal plates Two lifting columns 26 are slidably connected to the outer wall of the top of 25, and two springs 29 are slidably connected to the outer wall of the lifting column 26. The outer walls at the bottom of the two lifting columns 26 are fixed with the same U-shaped frame 27 by bolts, and the inner walls on both sides of the U-shaped frame 27 are rotatably connected with the same crimping roller 28; When the filter membranes 2 of different thicknesses are dried, the elastic force of the spring 29 can be used to make the crimping roller 28 produce a pressing force on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com