Blueberry jam condiment

A technology for blueberry jam and condiment, which is applied in the directions of food ingredients, the function of food ingredients, and protein-containing food ingredients, etc., to achieve the effects of improving color and taste, avoiding the problem of astringency, and being beneficial to human body absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

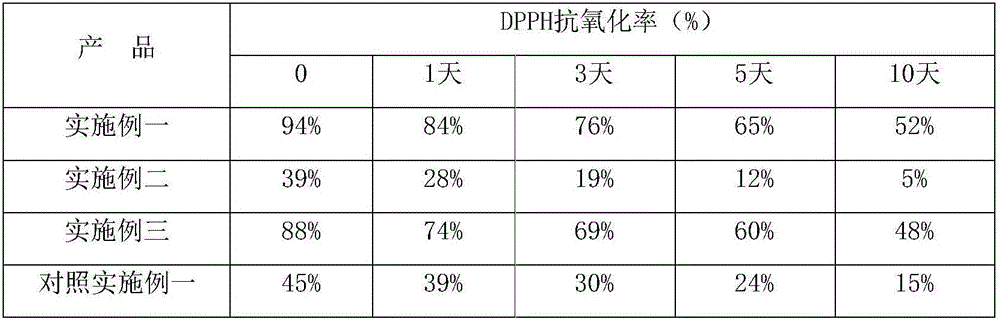

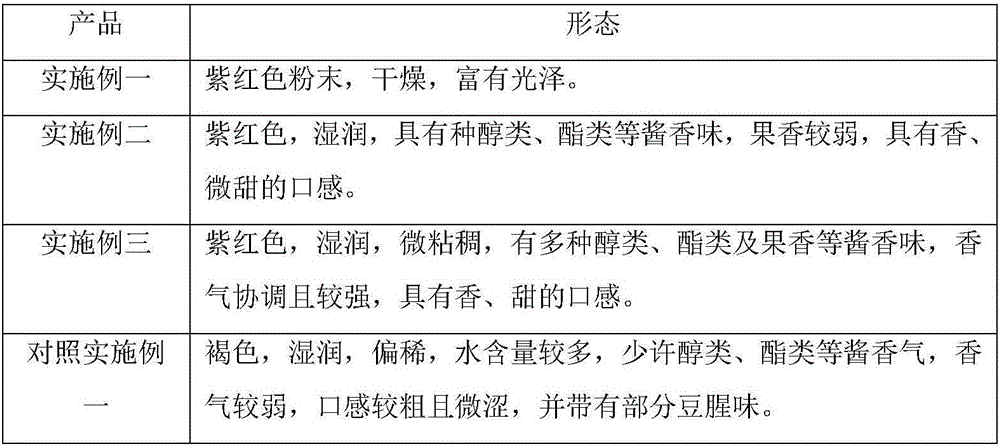

Examples

Embodiment 1

[0046] Embodiment one: the extraction method of blueberry pigment

[0047] 200 kg of non-rotten blueberry raw materials are selected, washed, air-dried at 45-55° C. to control the water content of the blueberries at 30-40 percent, and the blueberries are mashed and beaten to obtain blueberry pulp. Take 150L of blueberry pulp, add 300L of 70% ethanol aqueous solution, adjust the pH value to 4 with 0.1mol / L hydrochloric acid, ultrasonically extract for 35 hours, filter with 2 layers of gauze, repeat twice, combine the filtrates, and extinguish the filter residue at 100-110°C Bacteria for 10-30 minutes for later use, the resulting filtrate was concentrated under reduced pressure below 50°C to 1 / 30 of the original volume, adsorbed on XDA-8 macroporous resin, and gradient eluted with 12BV of 40-80% ethanol aqueous solution, collected The eluate was obtained, and the eluate was concentrated to dryness under reduced pressure below 50° C. to obtain blueberry pigment.

Embodiment 2

[0048] Embodiment 2: a kind of blueberry jam condiment

[0049] Rinse 1000kg of fresh soybeans with water for 10 minutes to remove impurities, then soak them in 8000L of water at a temperature of 45-50°C for 130 minutes, so that the absorption rate of soybeans is 80%, and the volume expansion rate of soybeans is 120-130 %, and then put it into a pot for steaming. After boiling the water, steam it with steam for 60 minutes, then steam it with small steam for 120 minutes until it is fully cooked. Add 400L of cooled boiled water to the boiled soybeans, crush, beat, stir evenly, sterilize, heat to 100°C, and keep for 20 minutes to obtain cooked soybeans after beating, take 1000kg of cooked soybeans after beating, and cool them To normal temperature, inoculate with 100L mucor spore suspension, put it into a culture room at 18-20°C, and ferment aerobically for 5 days to obtain fermented mold base. Take 100kg of fermented mold germ, filter it once with a ceramic membrane to obtain ...

Embodiment 3

[0051] Embodiment three: a kind of preparation method of blueberry jam condiment

[0052] Rinse 1000kg of fresh soybeans with water for 10 minutes to remove impurities, then soak them in 8000L of water at a temperature of 45-50°C for 120 minutes, so that the absorption rate of soybeans is 80%, and the volume expansion rate of soybeans is 120-130 %, and then put it into a pot for steaming. After boiling the water, steam it with steam for 60 minutes, then steam it with small steam for 120 minutes until it is fully cooked. Add 400L of cooled boiled water to the boiled soybeans, crush, beat, stir evenly, sterilize, heat to 100°C, and keep for 20 minutes to obtain cooked soybeans after beating, take 1000kg of cooked soybeans after beating, and cool them To normal temperature, inoculate with 100L mucor spore suspension, put into a culture room at 18-20°C, and ferment aerobically for 6 days to obtain fermented mold base. Take 100kg of fermented mold germ, filter it once with a cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com