Floating carrier

A carrier and overall technology, applied in the field of mechanical parts, can solve the problems of poor light transmission and air permeability of water bodies, unfavorable application of solar modules, unfavorable transportation and installation, etc., and achieve high environmental friendliness, enhanced anti-destructive performance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

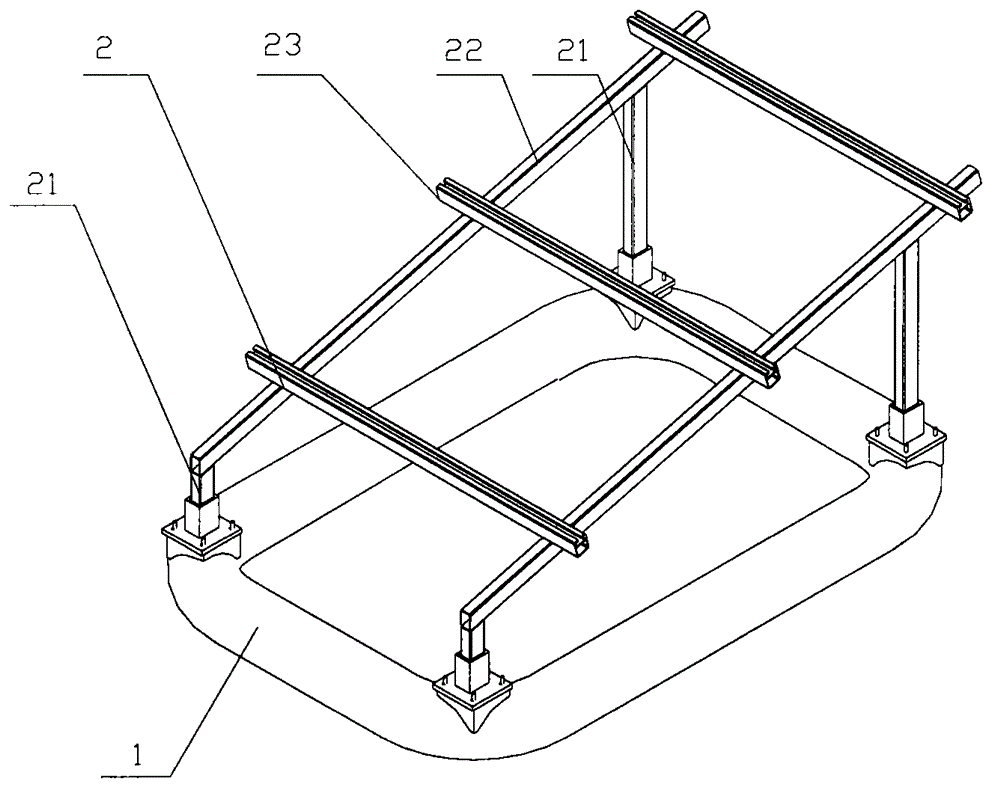

[0028] Such as figure 1 The floating carrier shown includes a floating piece 1 and a mounting bracket 2 that are fixed to each other. The floating piece 1 is a frame structure, wherein the floating piece 1 is an integrally formed rectangular frame structure, and the floating piece 1 and the mounting bracket 2 are made of FRP in non-metal-non-metal composite materials. In order to meet the installation needs of solar cells, the angle between the installation surface of the installation bracket 2 and the horizontal plane is 15°, and the installation bracket 2 specifically includes four uprights 21 fixedly connected to the four corners of the floating member 1 , and the columns 21 are divided into two groups of different heights, wherein the two heights at the diagonal positions are different; the tops of the two adjacent columns 21 with different heights are connected by a support beam 22, and the two parallel columns Three position-adjustable installation beams 23 are arranged...

Embodiment 2

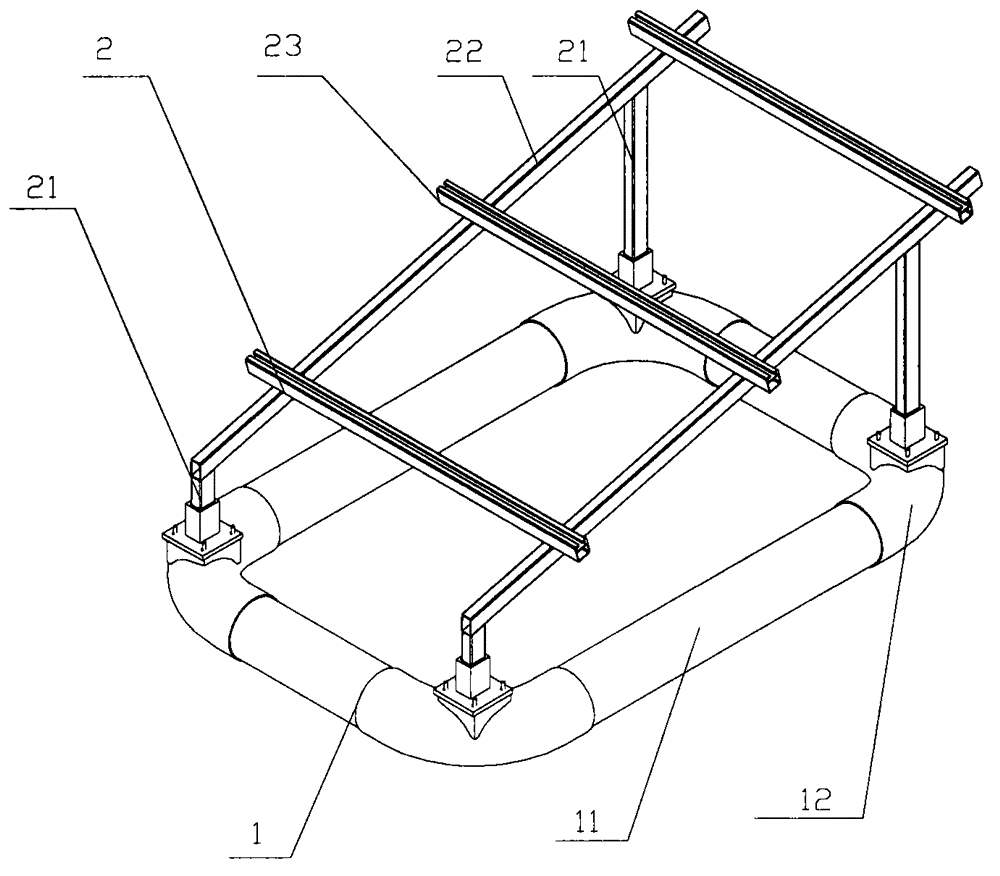

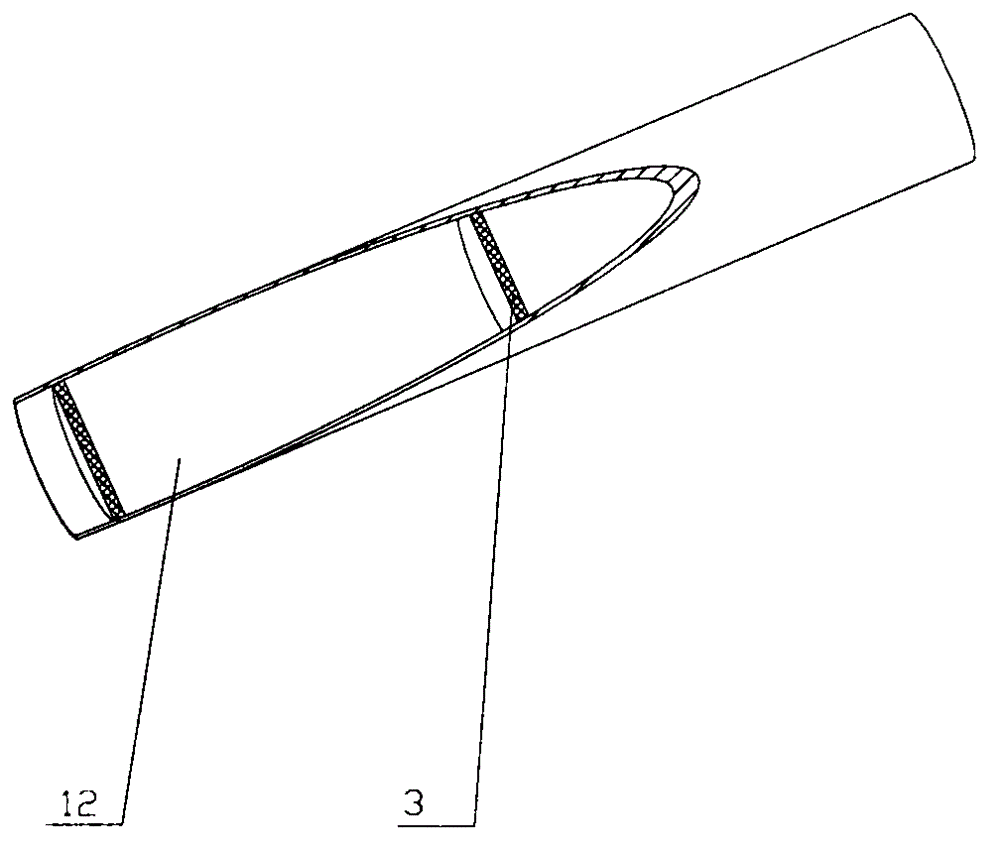

[0030] Such as figure 2 , image 3 The floating carrier shown includes a floating part 1 and a mounting bracket 2 fixedly connected to each other. The floating part 1 is a frame structure, wherein the floating part 1 is a split frame structure with rounded corners, and the material is glass fiber reinforced plastic. Specifically, the floating member 11 of the hollow straight pipe structure and the connecting member 12 of the hollow rounded elbow structure are glued to form an airtight hollow structure, and the floating member 11 of the hollow straight pipe and the hollow rounded elbow structure Baffles 13 are provided in the connecting members 12, so as to separate each of the floating members 11 and the connecting members 12 into a plurality of airtight hollow sections, so as to further enhance the safety performance of the floating carrier. The specific structure of the mounting bracket 2 is the same as the structure and material described in Embodiment 1, except that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com