Halftone mask plate and fabrication method of thin film transistor (TFT) substrate

A half-tone mask and substrate technology, which is applied in the photoengraving process of the pattern surface, the manufacture of semiconductor/solid-state devices, the originals for optical mechanical processing, etc. problems such as low rate, to avoid over-display and over-engraving, and eliminate insufficient yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

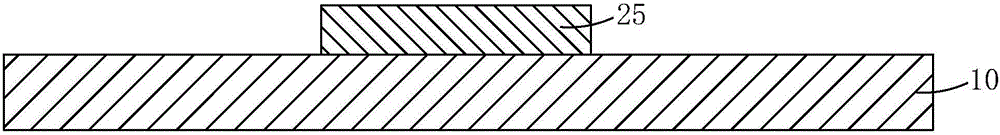

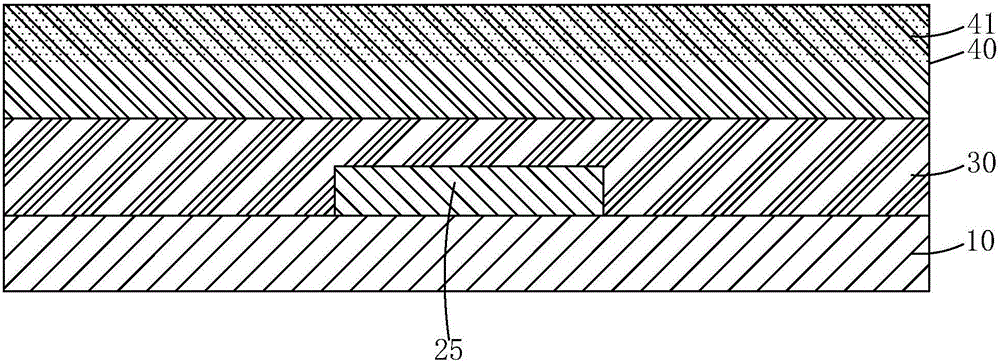

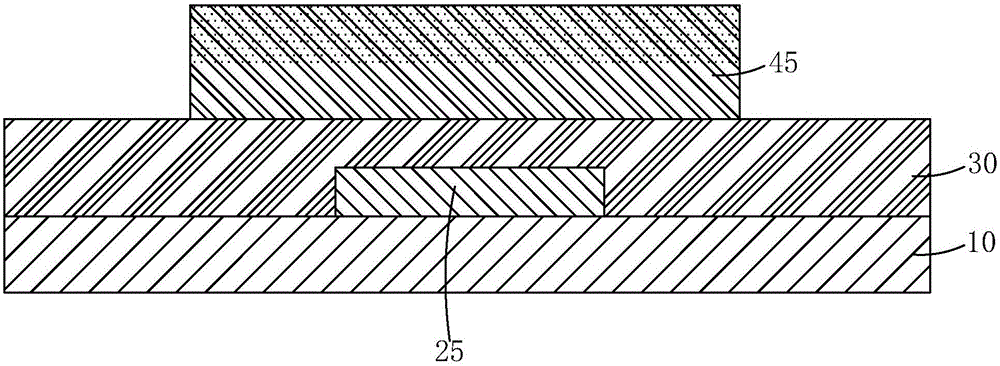

[0058] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0059] see Figure 9 , the present invention firstly provides a half-tone mask, including first and second opaque regions 910, 920 corresponding to the positions of the source and drain of the thin film transistor, and used for the active area of the thin film transistor. The U-shaped semi-transparent region 930 corresponding to the position of the U-shaped channel region of the layer, the two semi-transparent extension regions 940 located at the opening of the U-shaped semi-transparent region 930 and extending out of the opening, and the remaining full Light-transmitting region 950 .

[0060] Specifically, the first opaque area 910 includes a bar-shaped portion 911, the second opaque area 920 includes a U-shaped portion 921, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com