A detection method of powder equivalent diameter

A technology of equivalent diameter and detection method, applied in measurement devices, particle size analysis, scientific instruments, etc., can solve problems such as the lack of a unified detection method for equivalent particle diameter and the unclear equivalent calculation model, and to overcome the problems of agglomeration and surface Defects, shortened inspection cycle, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

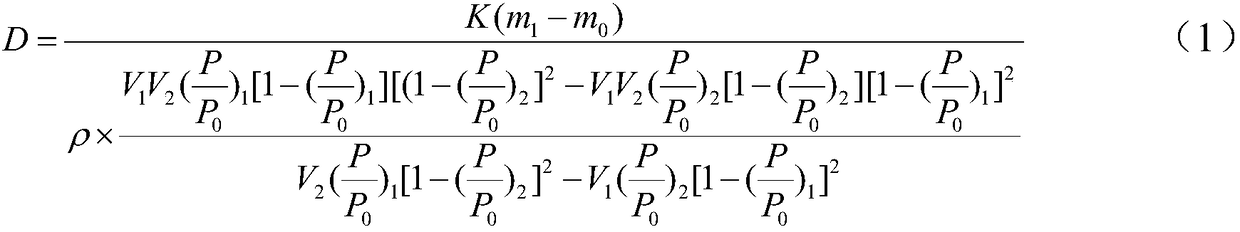

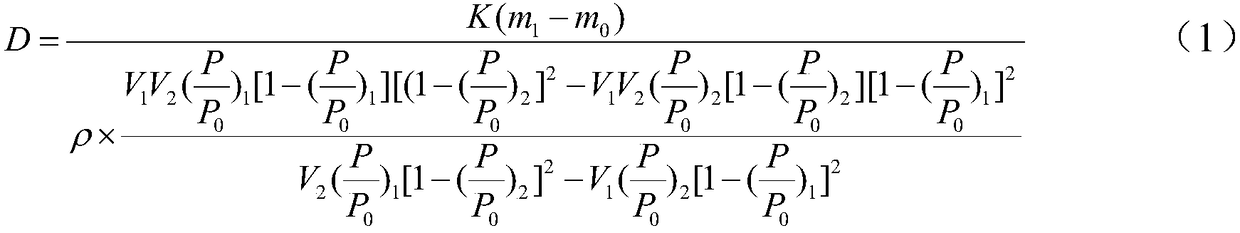

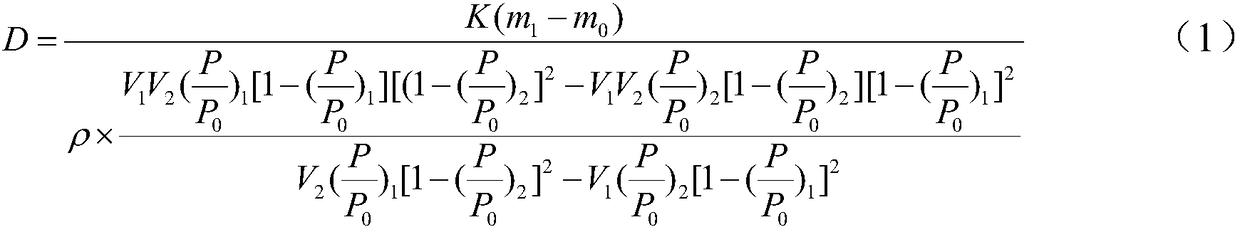

Method used

Image

Examples

Embodiment 1

[0038] A method for detecting the equivalent diameter of powder. The concrete steps of detection method described in the present embodiment are:

[0039] The first step, take a clean and dry sample tube, and measure the mass of the sample tube as m 0 =18.5881g; then take 0.0500-2.0000g of the powder to be tested and put it into the sample tube. The powder to be tested is Al 2 o 3 Powder, Al 2 o 3 The diameter of the powder is <0.1mm.

[0040] In the second step, the Al 2 o 3 The powder sample tube is fixed in the degassing station of the isothermal physical adsorption instrument, and degassed for 14-24 hours under the conditions of a vacuum of 0.05-0.2 Pa and a temperature of 100-200 °C.

[0041] Step 3: Cool the degassed sample tube to 25-35°C, and then backfill the cooled sample tube with high-purity nitrogen to normal pressure.

[0042] Step 4: Remove the sample tube backfilled with high-purity nitrogen from the degassing station of the isothermal physical adsorpti...

Embodiment 2

[0058] A method for detecting the equivalent diameter of powder. The concrete steps of detection method described in the present embodiment are:

[0059] The first step, take a clean and dry sample tube, and measure the mass of the sample tube as m 0 =15.7910g; then take 0.0500-2.0000g of the powder to be tested and put it into the sample tube. The powder to be tested is iron ore powder, and the diameter of the iron ore powder is less than 0.1mm.

[0060] In the second step, the sample tube containing the iron ore powder is fixed in the degassing station of the isothermal physical adsorption instrument, and degassed for 9-19 hours under the conditions of a vacuum degree of 0.05-0.2 Pa and a temperature of 150-250°C.

[0061] Step 3: Cool the degassed sample tube to 25-35°C, and then backfill the cooled sample tube with high-purity nitrogen to normal pressure.

[0062] Step 4: Remove the sample tube backfilled with high-purity nitrogen from the degassing station of the isoth...

Embodiment 3

[0078] A method for detecting the equivalent diameter of powder. The concrete steps of detection method described in the present embodiment are:

[0079] The first step, take a clean and dry sample tube, and measure the mass of the sample tube as m 0 =14.5989g; then take 0.0500-2.0000g of the powder to be tested and put it into the sample tube. The powder to be tested is elemental Al powder, and the diameter of the elemental Al powder is less than 0.1 mm.

[0080] In the second step, the sample tube containing the elemental Al powder is fixed in the degassing station of the isothermal physical adsorption instrument, and degassed for 4-14 hours under the conditions of a vacuum degree of 0.05-0.2Pa and a temperature of 200-300°C.

[0081] Step 3: Cool the degassed sample tube to 25-35°C, and then backfill the cooled sample tube with high-purity nitrogen to normal pressure.

[0082] Step 4: Remove the sample tube backfilled with high-purity nitrogen from the degassing station ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com