Visualized testing device for cavitation-cavitation erosion relation measurement

A technology of cavitation cavitation and test equipment, which is applied in the direction of measuring equipment, testing wear resistance, instruments, etc., can solve the problem that cavitation cannot be measured visually and quantitatively, and it is difficult to observe the generation area and dynamic characteristics of cavitation groups etc. to achieve the effects of easy processing and acquisition, change of saturated vapor pressure, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

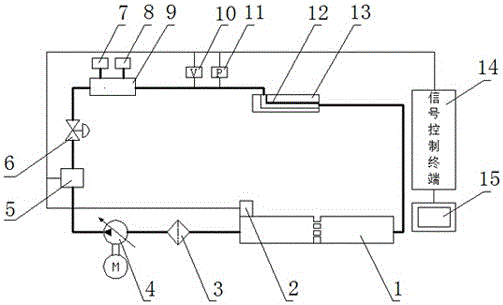

[0028] The invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] The structure of a visual test device for cavitation cavitation relationship measurement of the present invention is as follows: figure 1 As shown in the figure, P represents the pressure transmission unit, that is, the pressure sensor 11, V represents the flow transmission unit, that is, the flow sensor 10, and the thick solid line represents the pipeline. The test device includes fuel supply system, reaction system and measurement system.

[0030] The fuel supply system is used to ensure the self-circulation flow of fuel. The fuel supply system includes fuel tank 1, diesel filter 3, pump station 4, oil pressure regulating valve 5, adjustable butterfly valve 6, compressor 7, vacuum pump 8 and buffer section 9 The fuel tank 1 is provided with a heating tile 2 for opening and closing according to the test requirements, and the fuel is extracted from the fuel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com