Boiler cold state aerodynamic field out-of-furnace remote control measurement system

An aerodynamic field and measurement system technology, which is applied in aerodynamic tests, measurement devices, and machine/structural component testing, can solve problems affecting the accuracy of test results, interfering with air flow fields, and low work efficiency. The effect of improving occupational health, reducing disturbance, and making the device easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: It should be emphasized that the embodiments of the present invention are illustrative rather than restrictive, so the present invention is not limited to the implementation described in the specific embodiments. For example, all other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

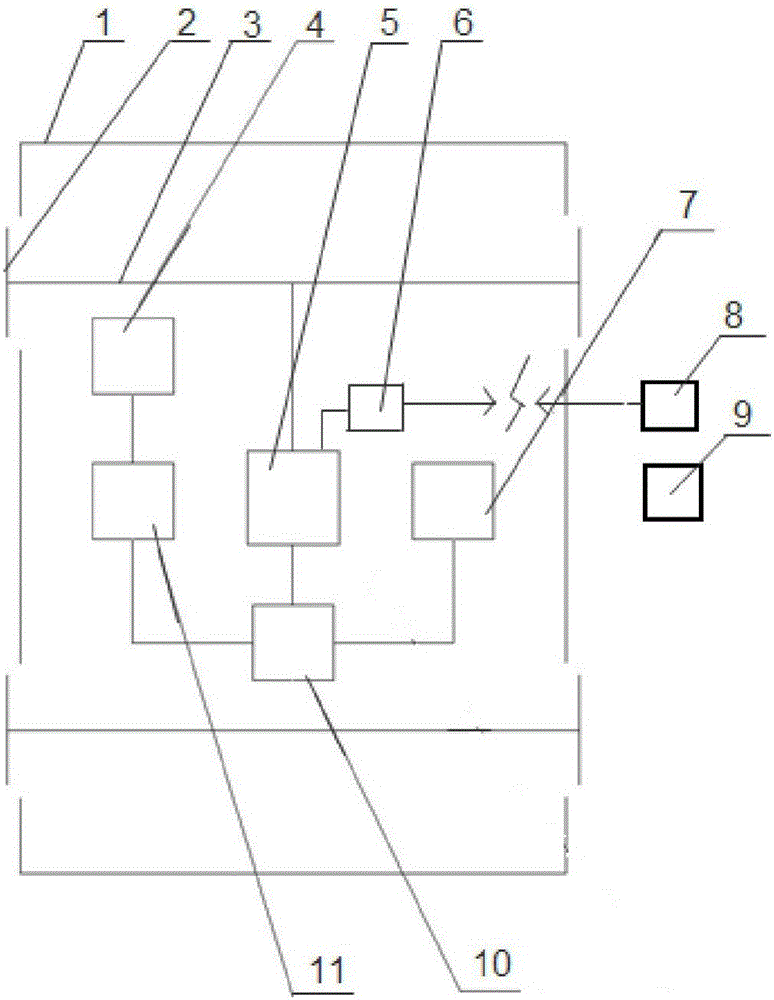

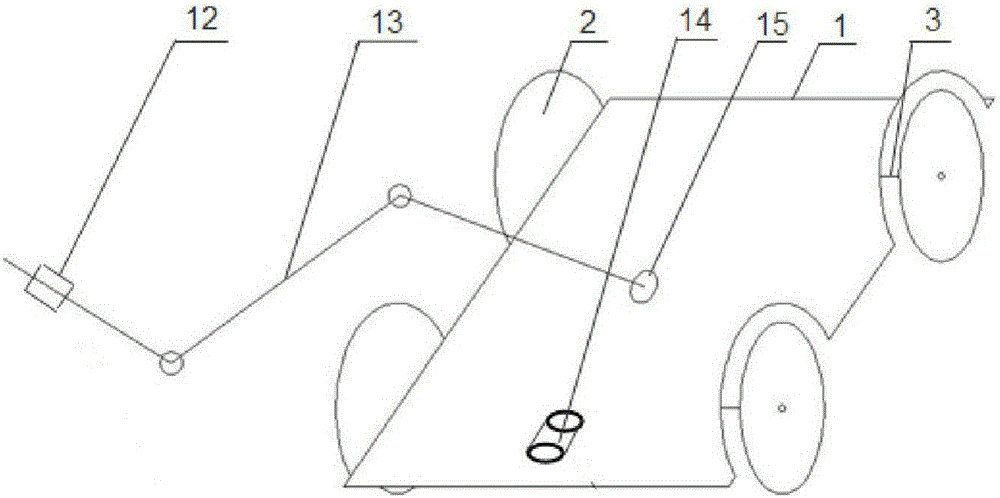

[0020] A remote control measurement system outside the boiler cold aerodynamic field, such as figure 1 As shown in or 2, the measurement system is composed of the test robot part in the furnace, the remote control part and the data processing part outside the furnace.

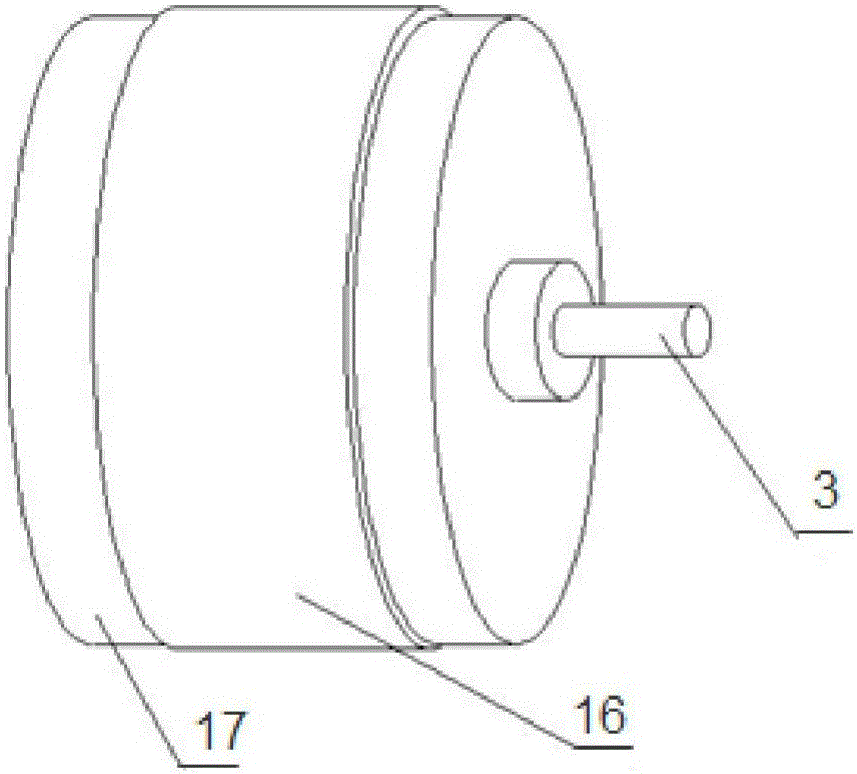

[0021] Among them, the test robot part includes a load-carrying frame 1, two front and rear axles 2 are installed at the bottom of the load-bearing frame, rollers 3 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com