Wear-resistant cable bridge frame

A cable tray, wear-resistant technology, applied in the direction of pipeline supports, electrical components, pipes/pipe joints/fittings, etc., can solve the problems of reducing the current carrying capacity of the cable, the heat of the cable cannot be dissipated in time, and the fire is easy to occur, so as to ensure emergency Requirement, loss reduction, long working time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

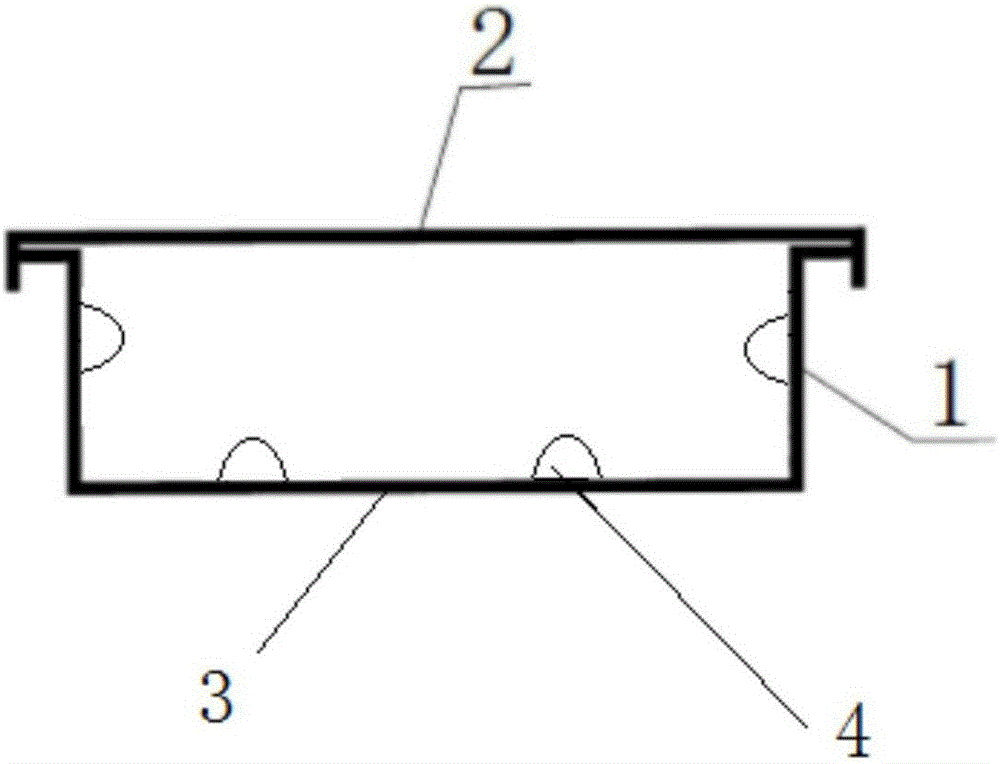

[0014] Such as figure 1 As shown, a wear-resistant cable tray is characterized in that it includes a bridge main body and a bridge cover plate 2, the bridge main body and the bridge cover plate 2 are inserted into each other, and the bridge main body includes a bridge bottom plate 3 and a bridge side plate 1. Both the bridge bottom plate 3 and the bridge side plate 1 are provided with reinforcing ribs 4. The bridge bottom plate is provided with multiple sets of brackets, and the brackets are covered with wear-resistant rubber sleeves. The cross-section of the reinforcing ribs is trapezoidal or elliptical. shape, all protruding to the inside, through the setting of reinforcing ribs, the strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com