Inter-pressure counter-rotating impeller mechanism

An impeller, forward rotation technology, applied in the field of inter-pressure and counter-rotating impeller mechanisms, can solve problems such as shock waves and limited application, and achieve the effects of high efficiency, reduction of stages, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

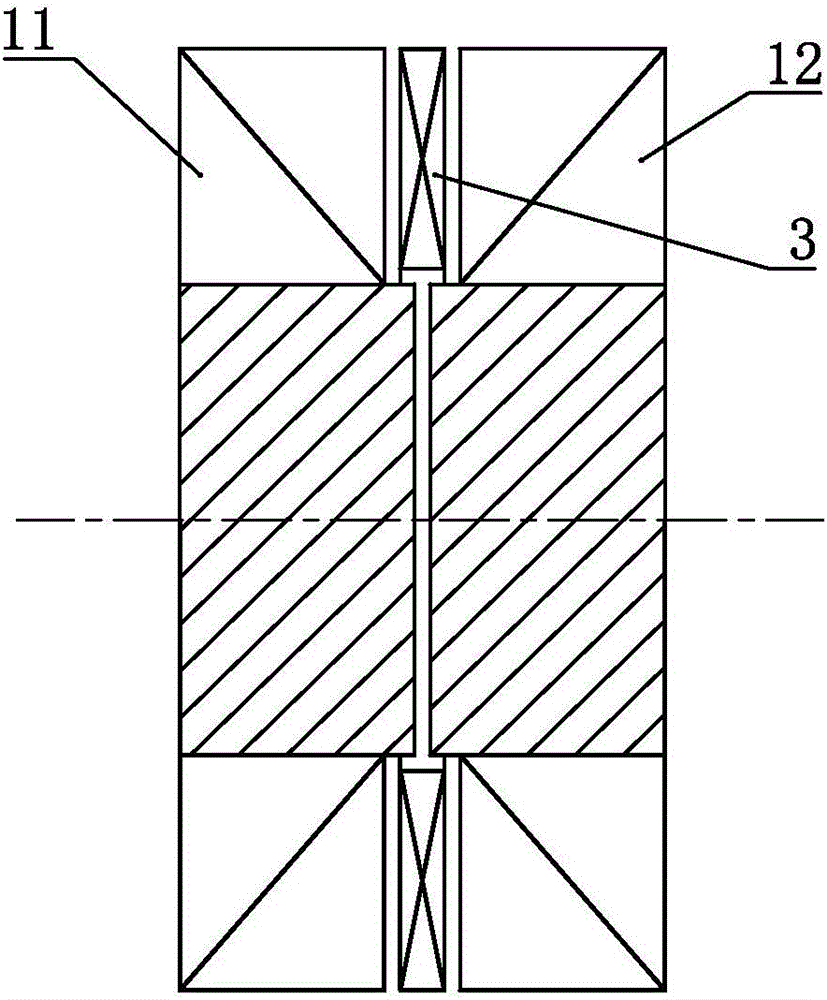

[0031] like figure 1 The shown inter-pressure counter-rotating impeller mechanism includes a forward-rotating impeller 11 and a counter-rotating impeller 12, and the forward-rotating impeller 11 and the counter-rotating impeller 12 are arranged correspondingly. A booster channel 3 is provided between 12.

[0032] In this embodiment, both the forward-rotating impeller 11 and the counter-rotating impeller 12 are of axial flow type.

Embodiment 2

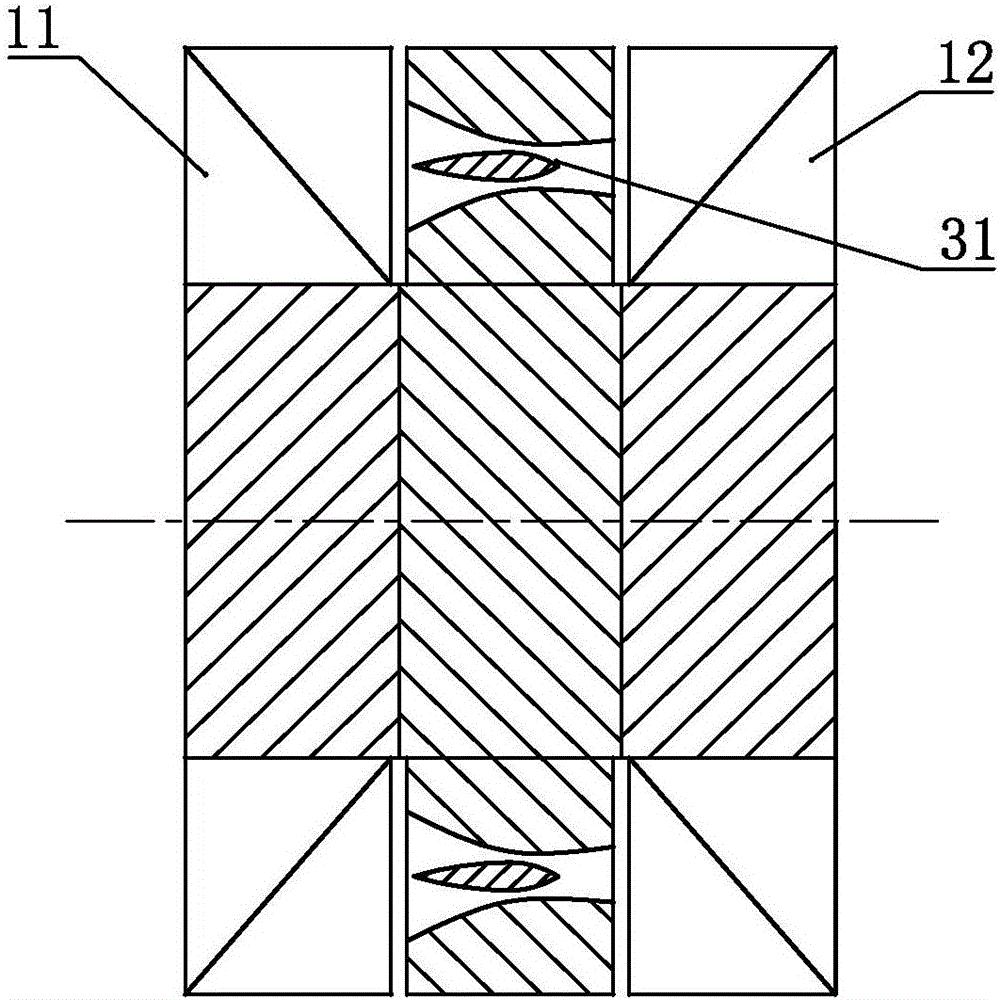

[0034] like figure 2 In the shown inter-pressure counter-rotating impeller mechanism, on the basis of Embodiment 1, the boosting channel 3 is set as a punching channel 31 .

Embodiment 3

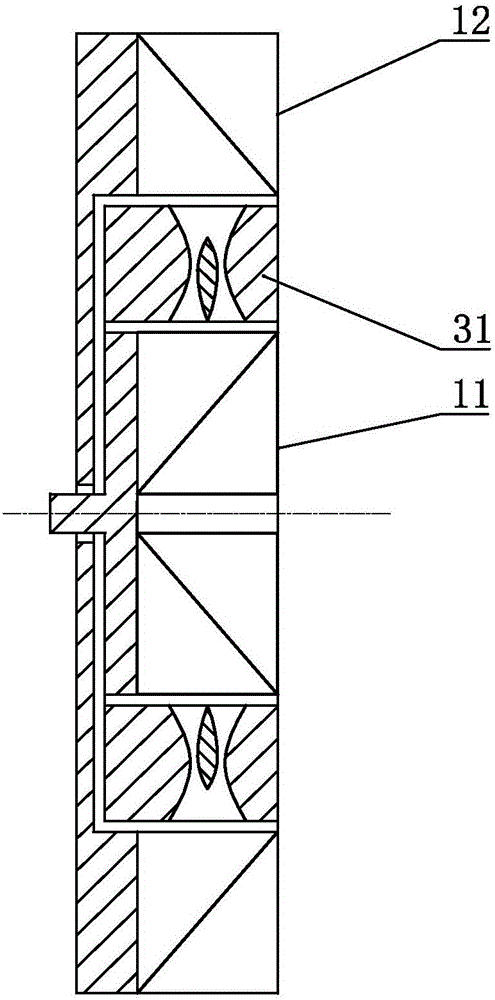

[0036] like image 3 The difference between the shown inter-pressure counter-rotating impeller mechanism and Embodiment 1 is that the forward-rotating impeller 11 and the counter-rotating impeller 12 are set as radial flow, and the boosting channel 3 is set as a stamping Channel 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com