A kind of drilling tool assembly and drilling technology for l-shaped ground pre-grouting drilling with a depth of one thousand meters

A drilling tool assembly and pre-grouting technology, which is applied in the field of mining machinery, can solve the problems of high rock powder up-return resistance, difficult tripping and drilling, and sticking, so as to improve drilling efficiency, improve construction quality, and improve drilling efficiency. Smooth track effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

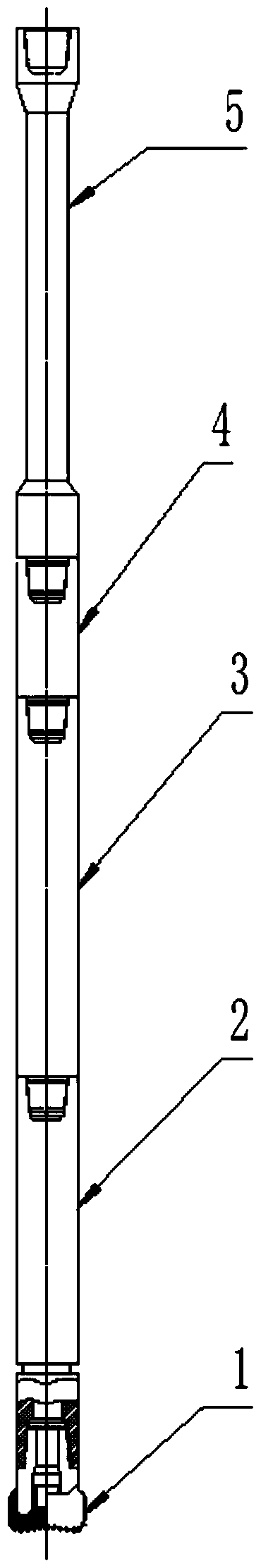

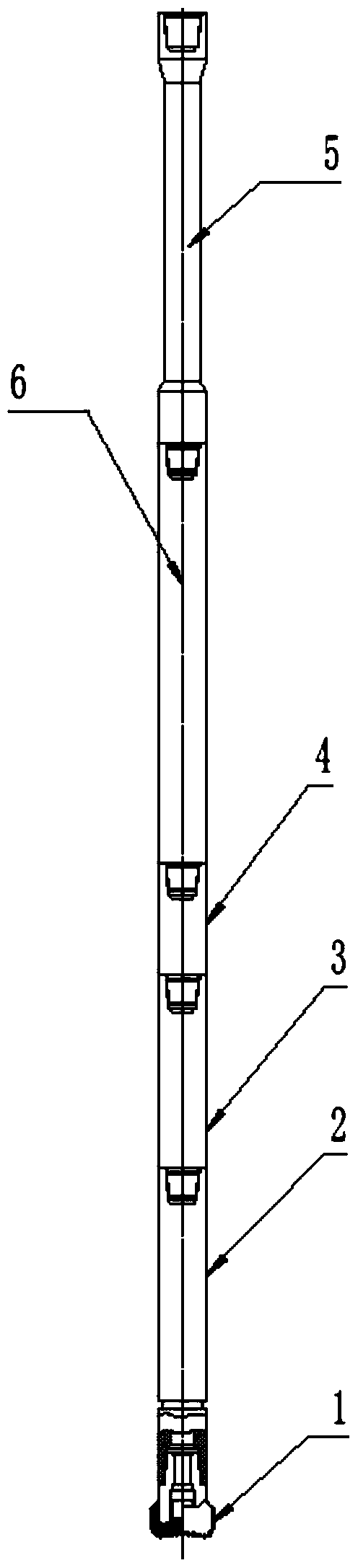

[0026] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0027] Take the L-shaped hole ground pre-grouting reinforcement project of the underground roadway in Xinhu Coal Mine, Guoyang County, Anhui Province as an example.

[0028] In this embodiment, a total of 3606m is drilled, including a total of 1806m in the deflection section and a total of 600m in the horizontal section. in:

[0029] (1) Drilling in straight hole section

[0030] When drilling open holes, the drilling tool assembly used includes Ф215.9mm roller cone bit, Ф159mm drill collar and Ф73mm short drill pipe; the drilling parameters are: drilling pressure 0.3~0.5t; drilling speed: 30~40r / min; Volume: 990L / min; when drilling, the drilling rig rotates slowly at low pressure, and circulates mud with a large displacement to ensure the verticality of the drilling hole.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com