A Modular Underground Down-the-hole Drilling Rig Adaptable to Low Environment

A down-the-hole drilling rig, modular technology, applied in the field of mining machinery, can solve the problems of damage to the dust catcher, dust leakage, damage, etc., to achieve the effect of strong drilling ability, light movement, and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

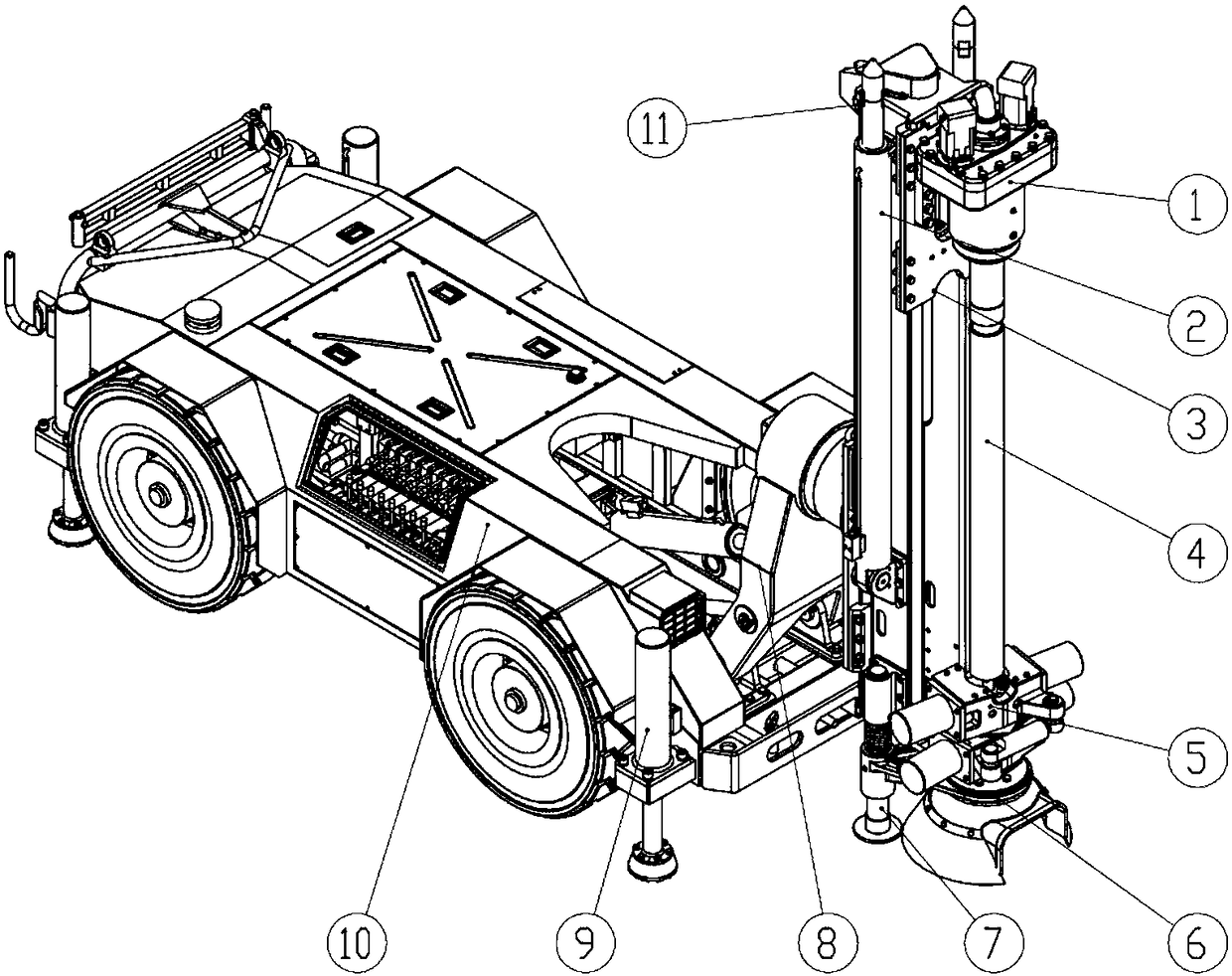

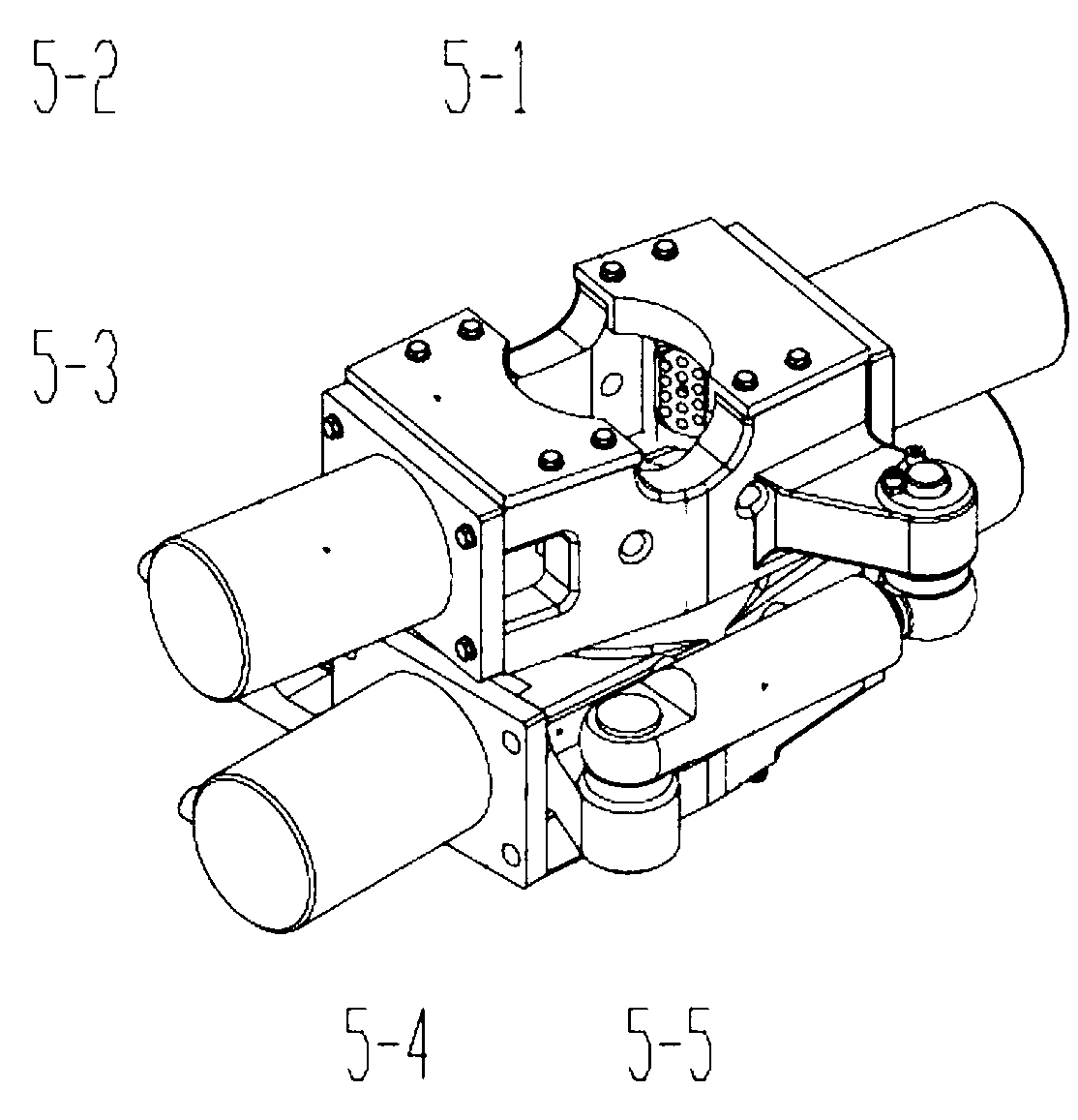

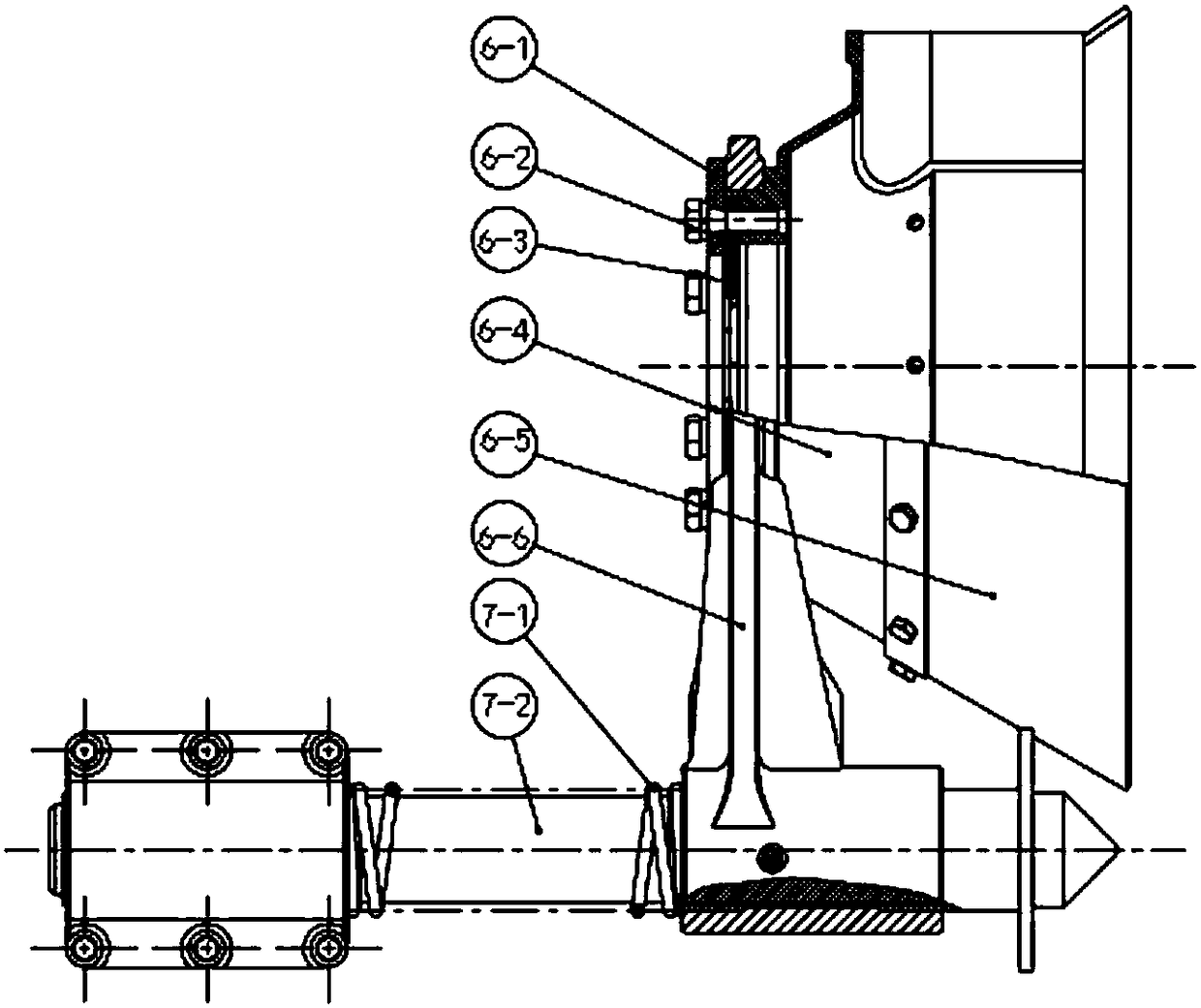

[0047] Such as figure 1 As shown, the present invention provides a modular subterranean down-the-hole drilling rig adaptable to a low environment, including a main engine and a chassis assembly 10, and the chassis assembly 10 is connected to the main engine through a drill arm assembly 8, Outrigger assemblies 9 are installed on the chassis assembly 10, and the main engine includes a slewing head assembly 1, an upper support cylinder 2, a thruster assembly 3, a rod unloader assembly 5, and a dust collection cover assembly 6 , the lower support mechanism 7 and the compensating oil cylinder 11, the slewing head assembly 1 is installed on the top of the front of the propeller assembly 3, the rod unloader assembly 5 is installed on the bottom of the front, the propeller The lower support mechanism 7 is installed below the side of the assembly 3, the lower support mechanism 7 is connected with the dust collection cover assembly 6, and the dust collection cover assembly 6 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com