Drainage device for shallow silt foundation treatment and laying method

A technology of silt foundation and drainage device, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long detection time, breakage, silting, etc., to improve sensitivity and accuracy, increase strength and stability, Not easy to deform and break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

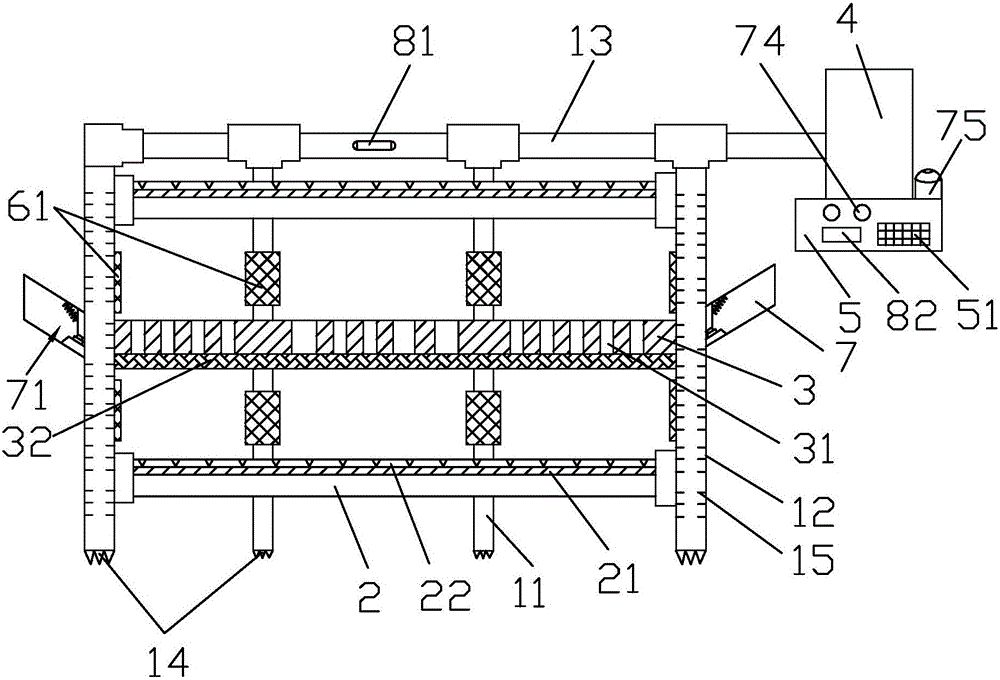

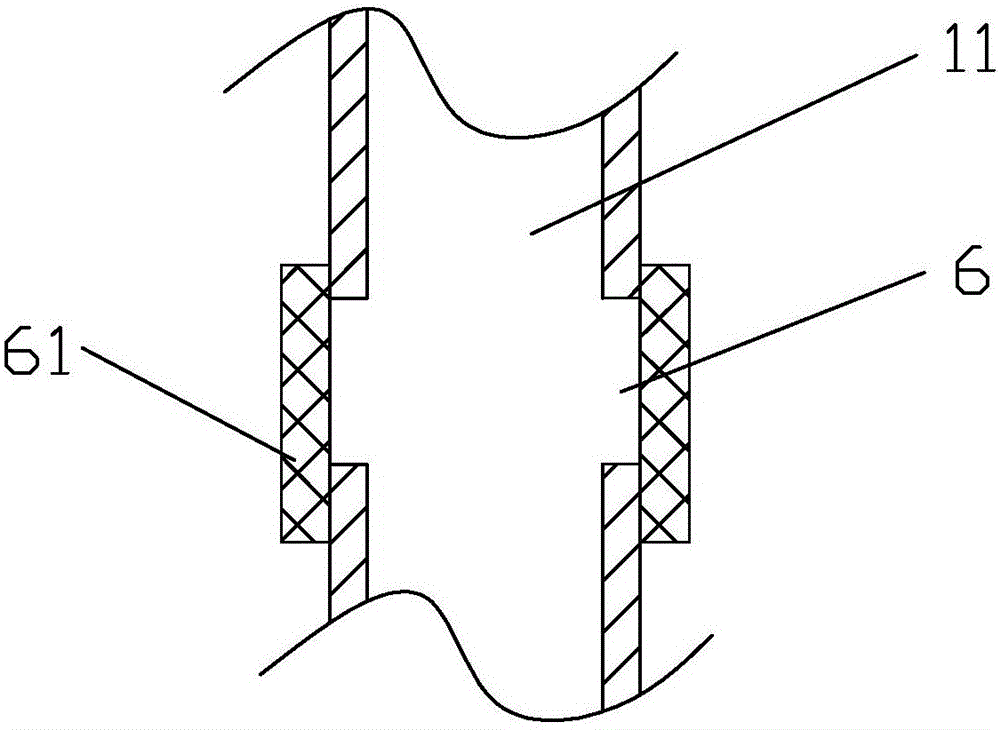

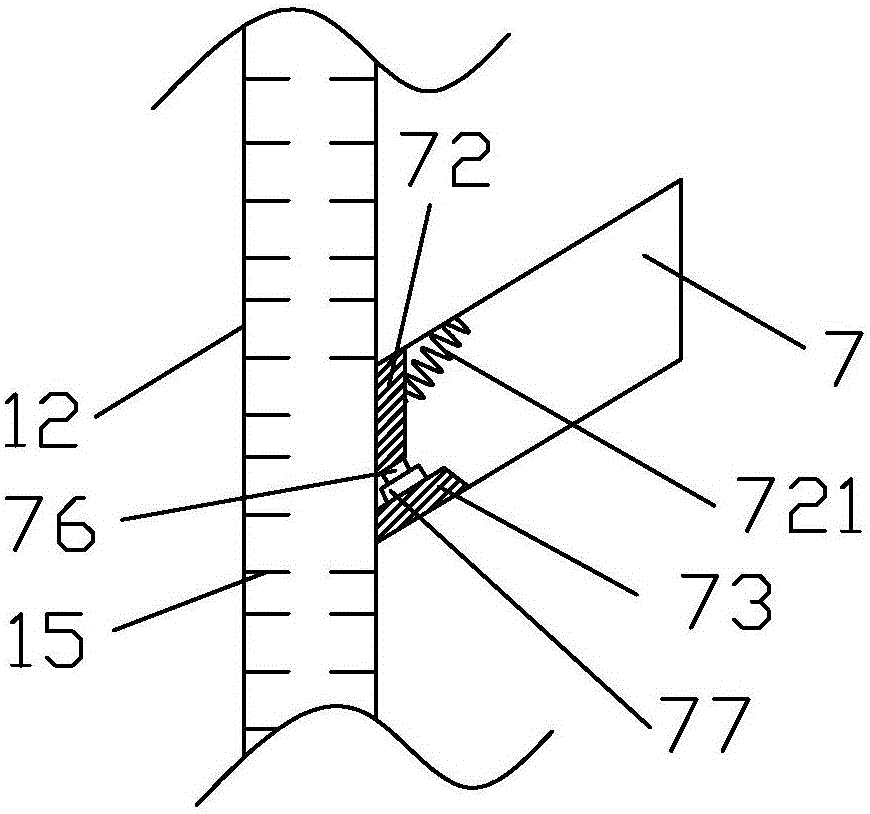

[0049] Such as Figure 1-4 Shown here is a drainage device for shallow silt foundation treatment of the present invention, including drainage pipes, drainage plates 2, mesh screens 3, vacuum equipment 4 and console 5, and the drainage pipes include main drainage pipe 11, auxiliary The drainage pipe 12 and the connecting pipe 13, the drainage plate 2 and the grid screen 3 are spaced from bottom to top, and multiple drainage plates 2 and grid screens 3 are arranged to improve drainage efficiency, increase the strength of the foundation, and reduce the clogging of silt during drainage. . A geotextile 21 and a woven fabric 22 are laid on the top of the drainage plate 2. The geotextile 21 is located on the upper side of the drainage plate 2, and the woven fabric 22 is located on the upper side of the geotextile 21. A layer of filter geotextile 21 is laid on the top surface of the drainage board 2 to prevent the passage of soil particles, so as to prevent the drainage channel from be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com