Floating two-stage buffer anti-collision system

A kind of anti-collision system and floating technology, which is applied in the direction of roads, road safety devices, roads, etc., can solve the problems of affecting the durability of bridge piers, the limited deformation of materials, and increasing the wave force of bridge piers, so as to facilitate installation and maintenance , reduce the maximum force, reduce the effect of the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

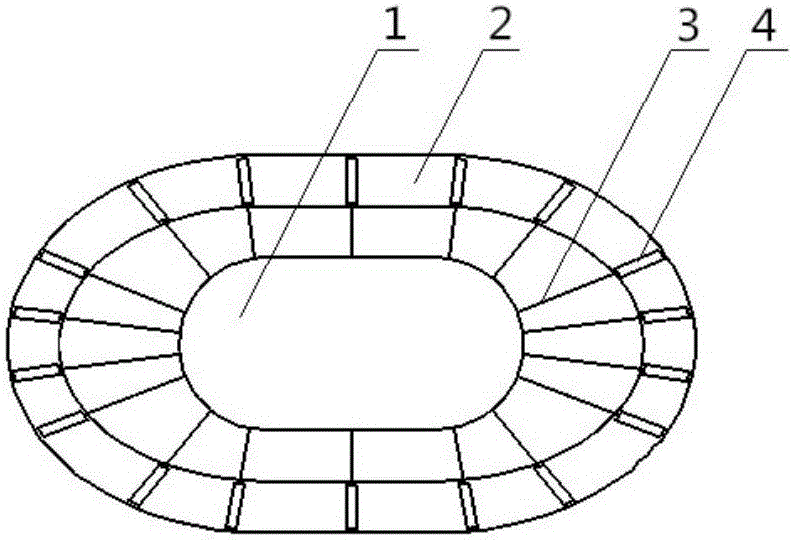

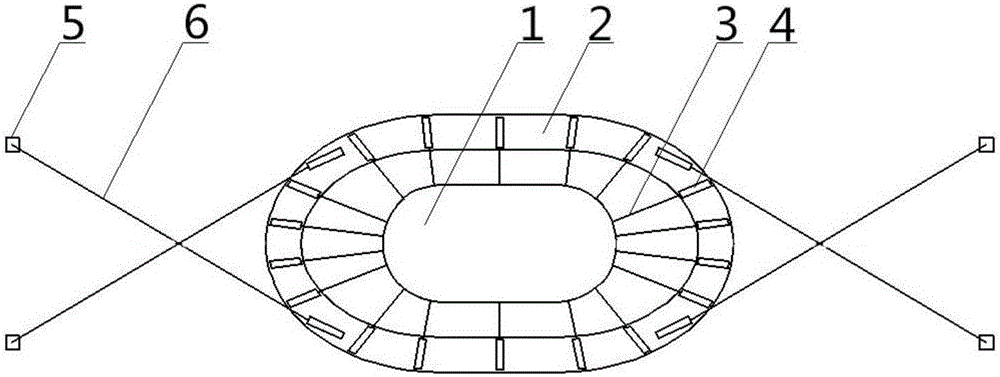

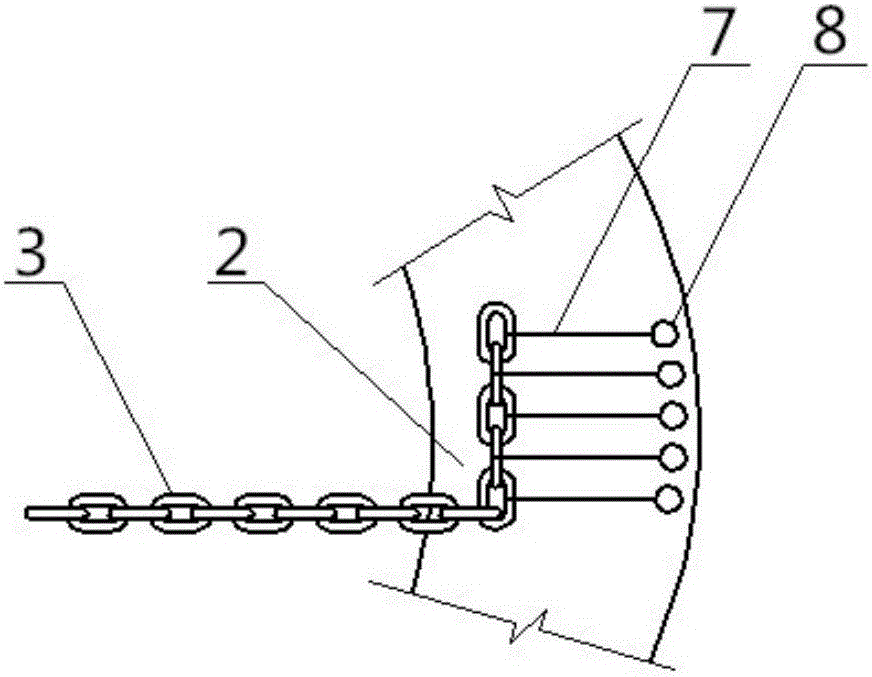

[0026] The floating two-stage buffer collision avoidance system includes a floating body 2, a connecting piece 3, a damper 4, an anchor 5, a cable chain 6, an energy-dissipating cable installation seat 8, a pultruded hole seat 10, a skeleton member 11, and a ring member 13 . The connector 3 is selected from rods, anchor chains and ropes; the energy dissipation material of the damper 4 is selected from energy dissipation cables 7 , metal strips 9 and metal connection materials 12 .

[0027] Such as figure 1 As shown, the floating body 2 is arranged around the pier 1, the dampers 4 are dispersedly installed on the floating body 2, and several connecting pieces 3 are arranged around the pier 1, one end of the connecting piece 3 is directly or indirectly connected to the pier 1, and the other end is connected to the damper 4. When the ship hits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com