A main girder bottom plate structure of a wide box girder bridge and its construction method

A technology of main girder web and bottom plate, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of insufficient stiffness of the bottom plate, difficult to play a role, and it is difficult to fully buckle the anti-collapsing steel bars, so as to prevent the bottom plate from cracking and enhance the rigidity. , the effect of less conflict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

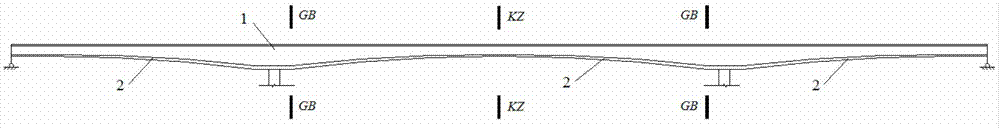

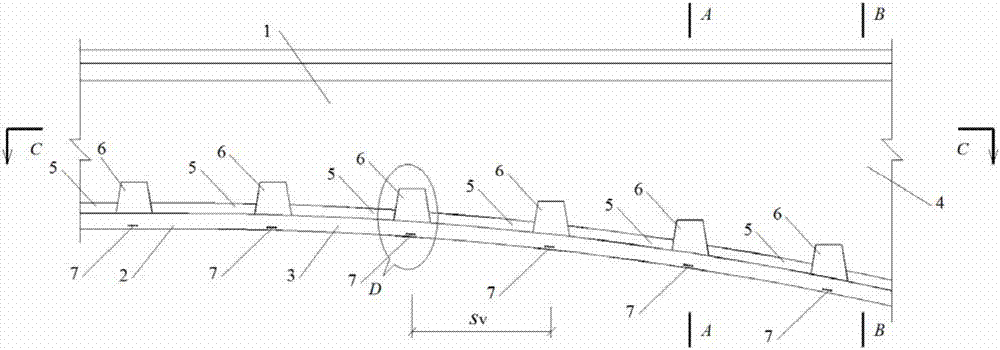

[0045] Such as figure 1 As shown, the main girder bottom plate structure of the wide box girder bridge in this embodiment is a prestressed concrete continuous rigid frame bridge, the bottom plate 2 is a curved surface, and the bottom plate prestressed steel bar 3 placed in the bottom plate 2 is also curved. . The span of the main girder 1 of the wide box girder bridge is 180m, the height of the mid-span girder is 4.5m, the girder height at the mid-fulcrum is 10.8m, and the width of the bottom plate is K=1140cm; The GB of the beam root is 72cm, and the average thickness of the bottom plate is d j = 50.0cm, which is 1 / 24 of the width of the bottom plate, and belongs to wide box girder bridge.

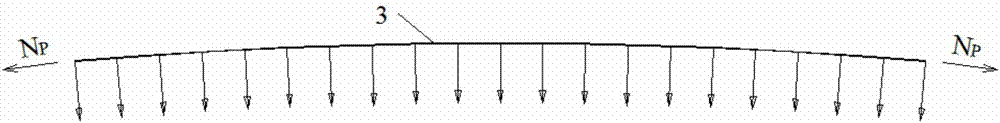

[0046] Such as image 3 As shown, the chord length of the mid-span bottom slab curve l=174.0m, the height f=10.8-4.5=6.3m can be obtained from the beam height at the mid-span a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com