Compact spinning chitin/tencel/cotton blended knitted fabric and production method thereof

A knitted fabric and compact spinning technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of difficult to achieve large-scale industrialization, high cost and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

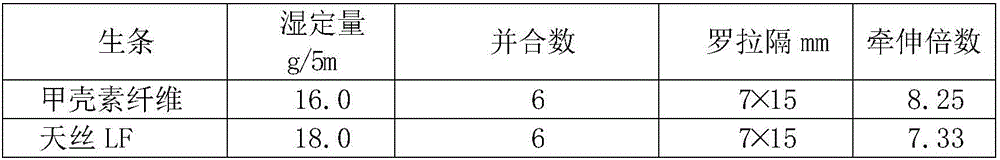

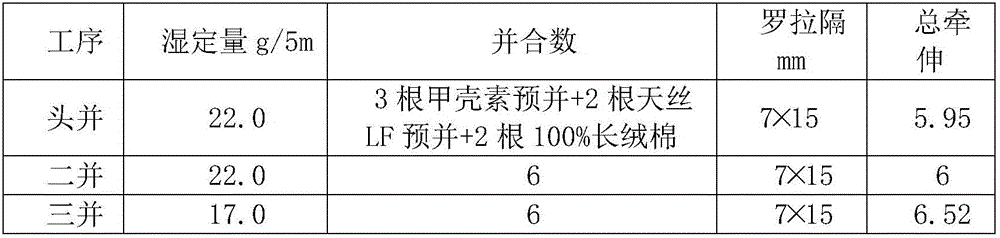

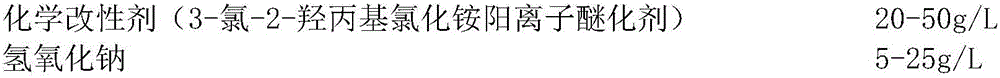

[0074] The compact-spun chitin / tencel / cotton blended knitted fabric is made of chitin fiber, tencel (LF) and long-staple cotton blended, spun with compact spinning technology, and processed by large circular machine weaving, dyeing and finishing. .

[0075] Compact spinning is a new spinning technology for spinning on an improved new ring spinning frame. A fiber aggregation zone is added before the traction device of the ring spinning frame, which basically eliminates the spinning between the front roller and the twisting point. In the yarn-twisting triangle area, after being output from the jaws of the front roller, the fiber strands pass through the special-shaped suction tube to coat the mesh ring. The strands are attached to the mesh ring and move together with the mesh ring due to the contraction and aggregation of the airflow. , Through the suction groove of the special-shaped tube, the whiskers are gathered and rotated, gradually turning from a flat ribbon to a cylinder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com