Fuel rod with high slagging resistance and preparation method thereof

A technology of fuel rods and pulverized materials, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of large ash content, high sulfur content, low combustion heat, etc., achieve complete combustion, reduce slagging rate, and improve the composition of raw materials simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of effective anti-slagging fuel rod, after the tomato vines after harvesting, oil-absorbed hair felt and fennel shells are softened by steam, they are extruded into fuel rods with a moisture content of less than 15% by a flat-film granulator ;

[0019] Among them, the weight ratio of tomato vine: hair felt after oil absorption: fennel shell is 6-7:2-3:1-2.

[0020] A method for preparing an effective slagging-resistant fuel rod, specifically comprising the following steps:

[0021] (1) Squeeze the tomato vines with a press to obtain dried tomato vines and squeezed juice with a moisture content of less than 10%, and crush the dried tomato vines into particles with a particle size of less than 3mm with a pulverizer to obtain crushed tomato vines for later use. Concentrate the squeezed juice to a quarter of its original volume at 35-45°C to obtain concentrated juice for later use;

[0022] (2) Dry the oil-absorbed hair felt at 60-70°C until the water content is le...

Embodiment 2

[0026] A kind of effective anti-slagging fuel rod, which is softened by steam after harvesting tomato vines, oil-absorbed hair felt, and fennel shells, and extruded by a flat-film granulator to form a fuel rod with a moisture content of less than 15%. ;

[0027] Among them, the weight ratio of tomato vine: hair felt after oil absorption: fennel shell is 6-7:2-3:1-2.

[0028] Its preparation method is identical with embodiment 1.

Embodiment 3

[0030] A kind of effective anti-slagging fuel rod, which is softened by steam after harvesting tomato vines, oil-absorbed hair felt, and fennel shells, and extruded by a flat-film granulator to form a fuel rod with a moisture content of less than 15%. ;

[0031] Among them, the weight ratio of tomato vine: hair felt after oil absorption: fennel shell is 6-7:2-3:1-2.

[0032] Its preparation method is identical with embodiment 1.

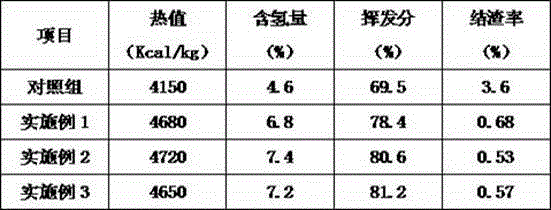

[0033] The control group is set to be mixed according to the raw materials in the present invention, after being dried to water content less than 15%, extruded into fuel rods with the same specifications as the product in the present invention with a flat die granulator, put into an incinerator and burn, and carry out Example to compare the main parameters, where the burning time is the burning time per kg of combustibles, and the following data are obtained:

[0034]

[0035] Table 1

[0036] It can be seen from the data in Table 1 that the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com