Automobile engine air valve clamp

A technology for automobile engines and valves, applied in pliers, hand-held tools, manufacturing tools, etc., can solve time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

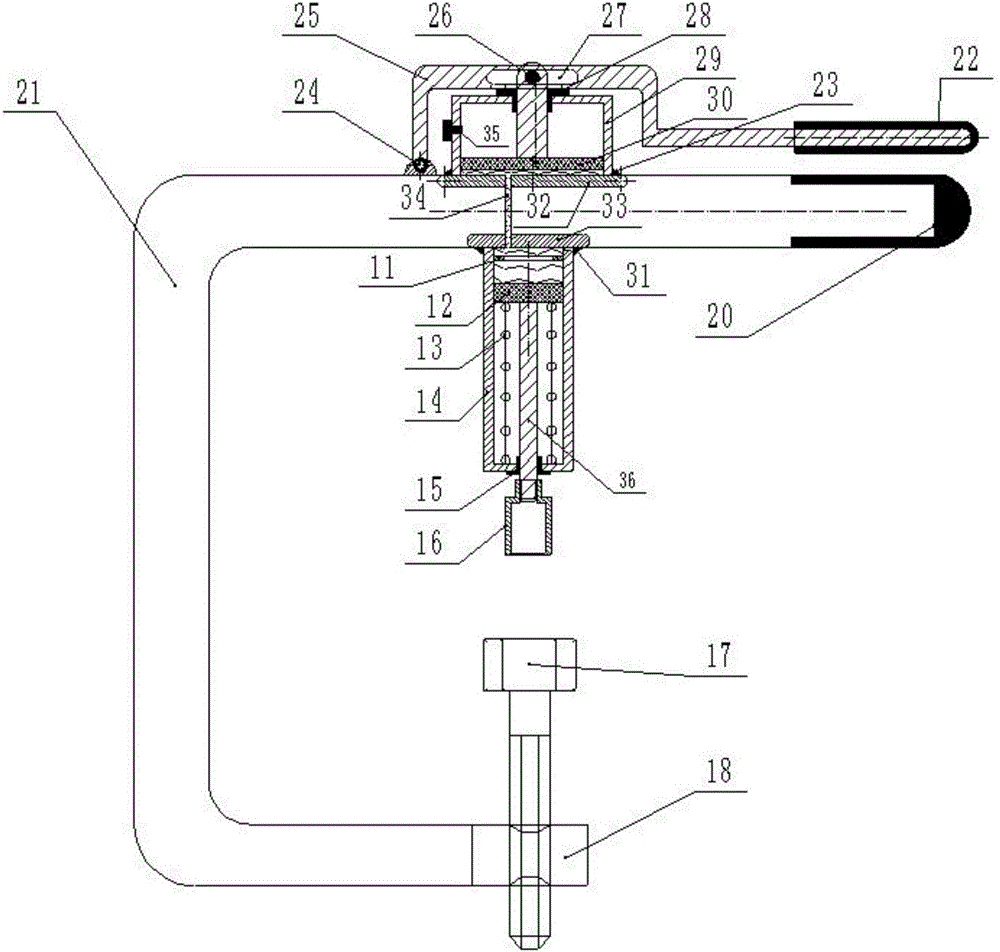

[0009] Combine below Attached drawing To this invention Automobile engine valve clamp Give further details;

[0010] by Figure 1 It can be seen that this implementation is Automobile engine valve clamp , By the limit stop ring (11), auxiliary hydraulic cylinder piston (12), return spring (13), auxiliary hydraulic cylinder (14), seal ring A (15), sleeve (16), adjusting bolt (17), Adjusting nut (18), main handle (20), valve clamp body (21), afterburner lever operating handle (22), master cylinder welding (23), hinge (24), afterburner (25), turn to Cancellation (26), waist hole (27), sealing ring B (28), main hydraulic cylinder (29), main hydraulic cylinder piston (30), auxiliary cylinder welding part (31), main cylinder backing plate (32), auxiliary Cylinder backing plate (33), communication hole (34), liquid injection hole (35), piston rod (36) constituted, said Automobile engine valve clamp It is characterized in that: a screw hole with internal teeth is drilled at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com