A graphite mold casting method for large thin-walled titanium alloy castings

A titanium alloy and graphite type technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of insufficient pouring of thin-walled parts, achieve the effects of improving surface quality, reducing cracks and other defects, and simplifying the operation of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A graphite type casting method of a large thin-walled titanium alloy casting, the method comprises the following steps: preparation of a graphite mold, assembly and casting of a graphite mold, wherein the graphite mold is assembled from the prepared graphite mold The graphite mold used for casting the air inlet casting is composed of 42 graphite moulds. Before the graphite mold is used to assemble the graphite mold, 33 of the graphite molds need to be coated. The coating treatment includes the following steps:

[0025] (1) Mix yttrium oxide and zirconia into a mixed powder according to a weight ratio of 95:5, then mix the mixed powder and silica sol according to a weight ratio of 4.5:1 to prepare a paint paste, and then add 1 drop to the paint paste defoamer, and stir until the paint paste appears fluidity, pour the diluent into it and stir until the viscosity of the paint reaches 15 g / min, to obtain the paint for brushing;

[0026] (2) Mix the mixed powde...

Embodiment 2

[0033] Embodiment 2: a graphite type casting method of a large thin-walled titanium alloy casting, the method comprises the following steps: preparation of a graphite mold, assembly and casting of a graphite mold, wherein the graphite mold is assembled from the prepared graphite mold The graphite mold used for casting the air inlet casting is composed of 42 graphite moulds. Before the graphite mold is used to assemble the graphite mold, 33 of the graphite molds need to be coated. The coating treatment includes the following steps:

[0034] (1) Mix yttrium oxide and zirconia into a mixed powder according to a weight ratio of 90:10, then mix the mixed powder and silica sol according to a weight ratio of 3:1 to prepare a paint paste, and then add 2 drops to the paint paste defoaming agent, and stir until the paint paste appears fluidity, pour the diluent into it and stir until the paint viscosity reaches 25 g / min, to obtain the paint for brushing;

[0035] (2) Mix the mixed powde...

Embodiment 3

[0042]Embodiment 3: a graphite type casting method of a large thin-walled titanium alloy casting, the method comprises the following steps: preparation of a graphite mold, assembly and casting of a graphite mold, wherein the graphite mold is assembled from the prepared graphite mold The graphite mold used for casting the air inlet casting is composed of 42 graphite moulds. Before the graphite mold is used to assemble the graphite mold, 33 of the graphite molds need to be coated. The coating treatment includes the following steps:

[0043] (1) Mix yttrium oxide and zirconia into a mixed powder according to a weight ratio of 92:8, then mix the mixed powder and silica sol according to a weight ratio of 6:1 to prepare a paint paste, and then add 1 drop to the paint paste defoamer, and stir until the paint paste appears fluidity, pour the diluent into it and stir until the viscosity of the paint reaches 20 g / min, to obtain the paint for brushing;

[0044] (2) Mix the mixed powder a...

PUM

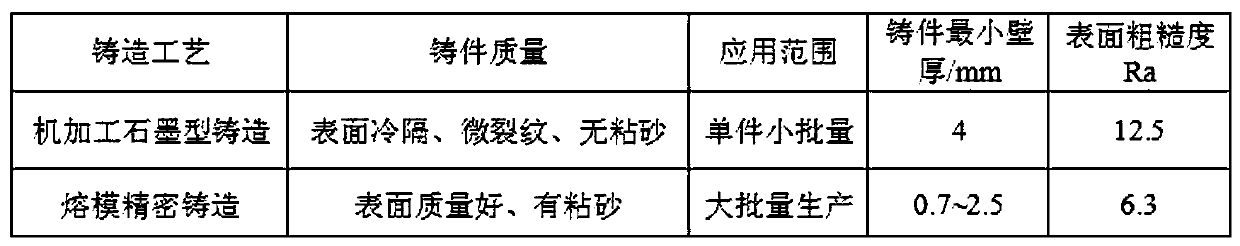

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com