Homocentric-squares-shaped imbedding composite hammer made of abrasion-resisting materials

A wear-resistant material and composite hammer technology, applied in grain processing and other directions, can solve problems such as affecting the crushing effect of the hammer, and achieve the effects of large kinetic energy, high crushing efficiency, and long service time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

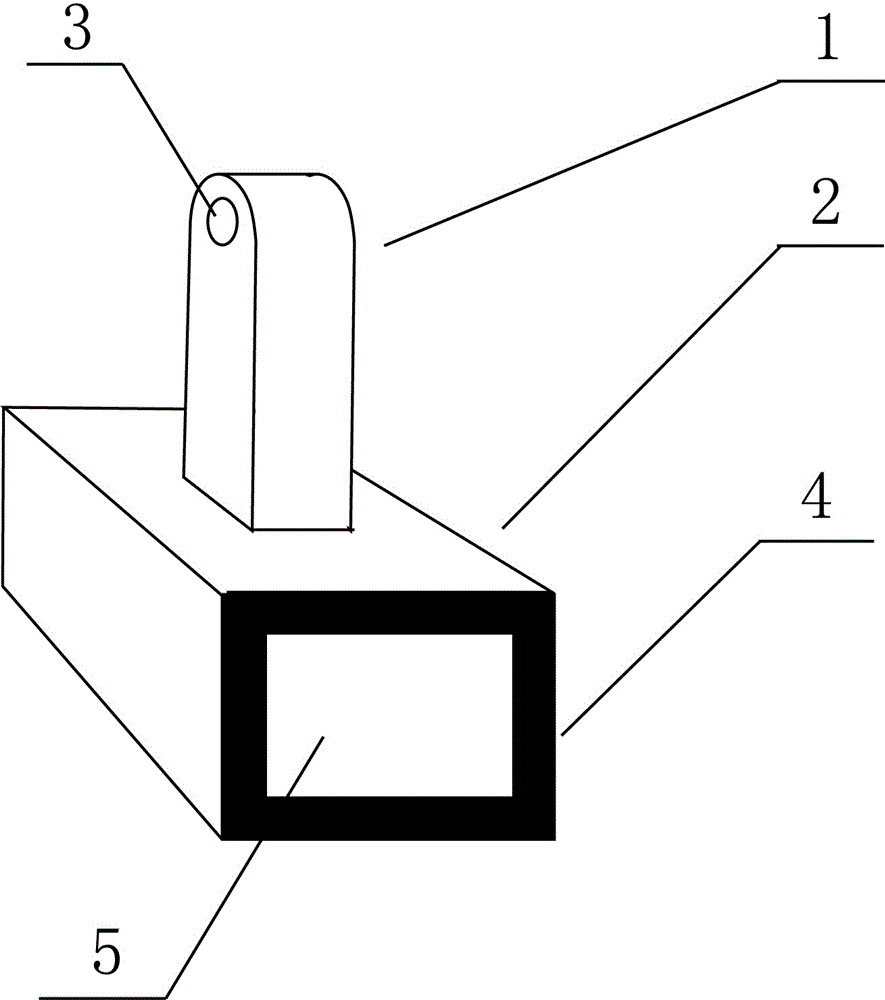

[0025] Embodiment 1: as figure 1 As shown, the composite hammer head of a wear-resistant material back-shaped casting is composed of a hammer handle (1), a hammer end (2), and a back-shaped casting body (4); the hammer handle (1) Combined with the hammer end (2); the inlay casting body (4) is wrapped outside the hammer end (2), and the back-shaped inlay casting body (4) includes four sides of left, right, upper and lower wear-resistant material casting; the back-shaped inlaid casting body (4) is wrapped around the periphery of the crushing surface (5) of the hammer end (2), and together constitutes the wear-resistant crushing surface (5) of the hammer end (2); the The back-shaped casting body (4) is made of high chromium cast iron, and the material of the hammer handle (1) and hammer end (2) is made of high manganese steel.

[0026] A wear-resistant material back-shaped casting composite hammer head, the manufacturing process includes the following steps:

[0027] Step 1: Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com