A kind of preparation method of perylene diimide functionalized copper oxide nanocomposite material

A nanocomposite material, perylene diimide technology, applied in the field of preparation of nanocomposite materials, to achieve the effect of strong selectivity, small size and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ① Add 0.171 g copper chloride (CuCl 2 ∙ H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100 °C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60° C. for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

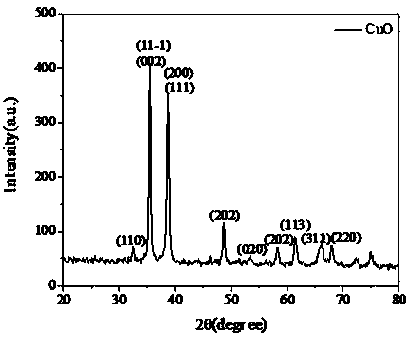

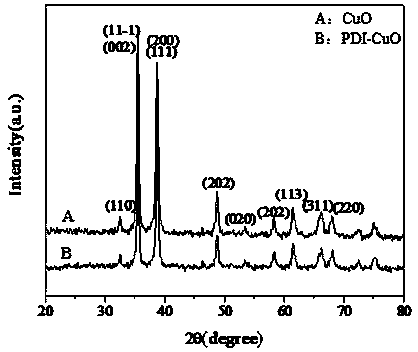

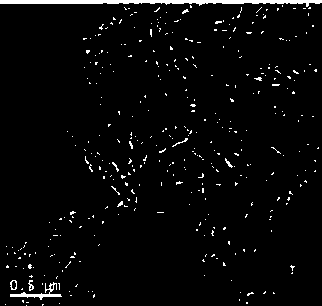

[0027] The resulting product was tested and the results were as follows: figure 1 , figure 2 , image 3 shown. from figure...

Embodiment 2

[0029] ① Add 0.1425 g copper chloride (CuCl 2 ∙ H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100 °C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60 °C for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

Embodiment 3

[0031] ① 0.21375 g copper chloride (CuCl 2 ∙H 2 O) Dissolve 0.348 g of sodium dodecylbenzenesulfonate into 10 mL of deionized water. Under the condition of stirring, 10 mL of 5M sodium hydroxide solution was added dropwise, and the stirring was continued for 0.5 h; then aged at room temperature for 4 h to obtain a suspension. The system was transferred to a 25 mL reactor and reacted at 100°C for 6 h. After centrifugation, washing, drying and calcination, copper oxide nanobelts are obtained. ②Weigh 2.5 mg of perylene diimide and completely dissolve it in 2.5 mL of N,N-dimethylformamide to form solution A. Add the above-mentioned synthesized copper oxide to A, sonicate for 0.5 h, centrifuge and rinse with deionized water and ethanol for 3 times, and dried at 60 °C for 4 h to obtain perylene diimide functionalized copper oxide nanocomposites.

[0032] On the basis of the above embodiments, the present invention needs to be explained as follows.

[0033] The raw material pery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com