Absorbent core production equipment for CNC adult diaper production line

A technology of adult diapers and production equipment, which is applied in the field of sanitary products production, can solve problems such as agglomeration, looseness, loss, and poor absorption performance, and achieve the effects of ensuring stability, ensuring mixing and adhesion, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

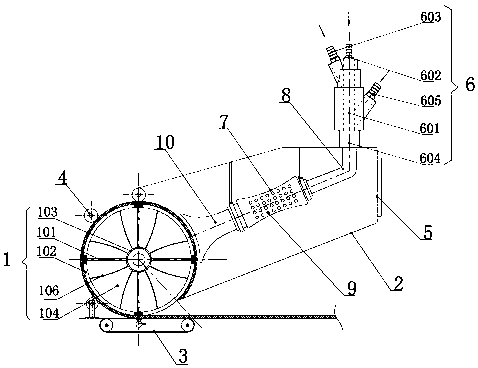

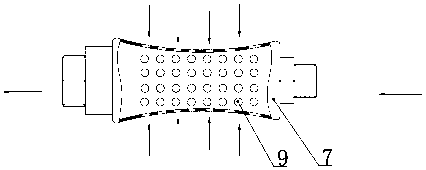

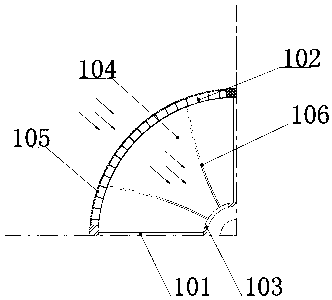

[0026] see Figure 1-Figure 5 , a kind of absorbent core production equipment of the numerical control adult diaper production line of the present invention, comprises adsorption mold wheel 1, the forming bin 2 that is sealed and arranged on the side of adsorption mold wheel 1, and the unloading conveying device 3 that is arranged at the lower part of adsorption mold wheel 1 , a plurality of pressing rollers 4 are arranged on the outside of the adsorption mold wheel 1, a wood pulp feeding port 5 is arranged at the outer end of the molding bin, and a polymer water-absorbing resin feeding material is also arranged on the molding bin 2 Mixing device, wherein the adsorption mold wheel 1 includes a wheel skeleton 101, a grid-shaped mold cavity 102 that is circumferentially arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com