Stuffed multi-purpose wheaten food machine

A pasta machine and stuffing technology, which is applied in application, dough processing, food science, etc., can solve the problems of unreasonable design, inability to wrap the stuffing in the dough, and difficulty in wrapping the stuffing without revealing the stuffing, so as to achieve a simple structure, The effect of low cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

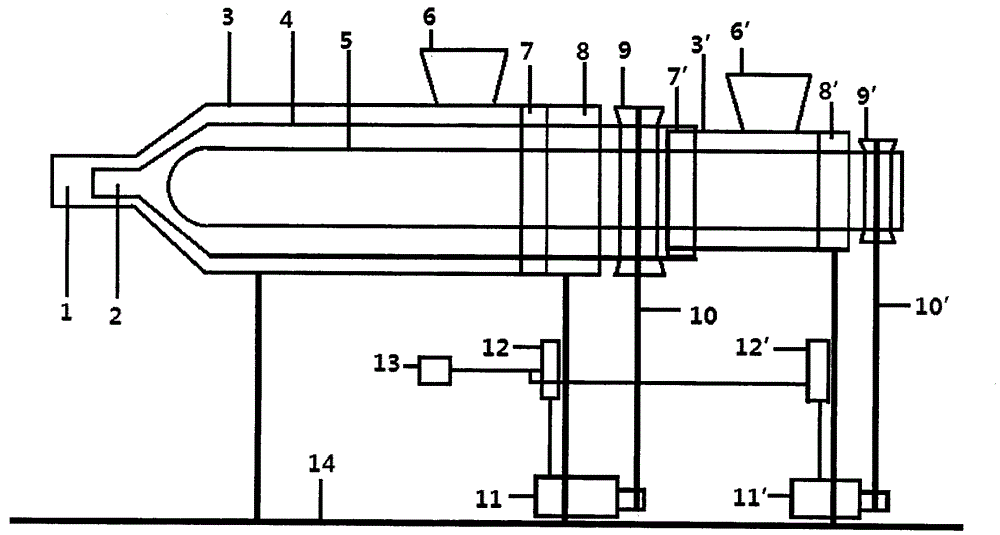

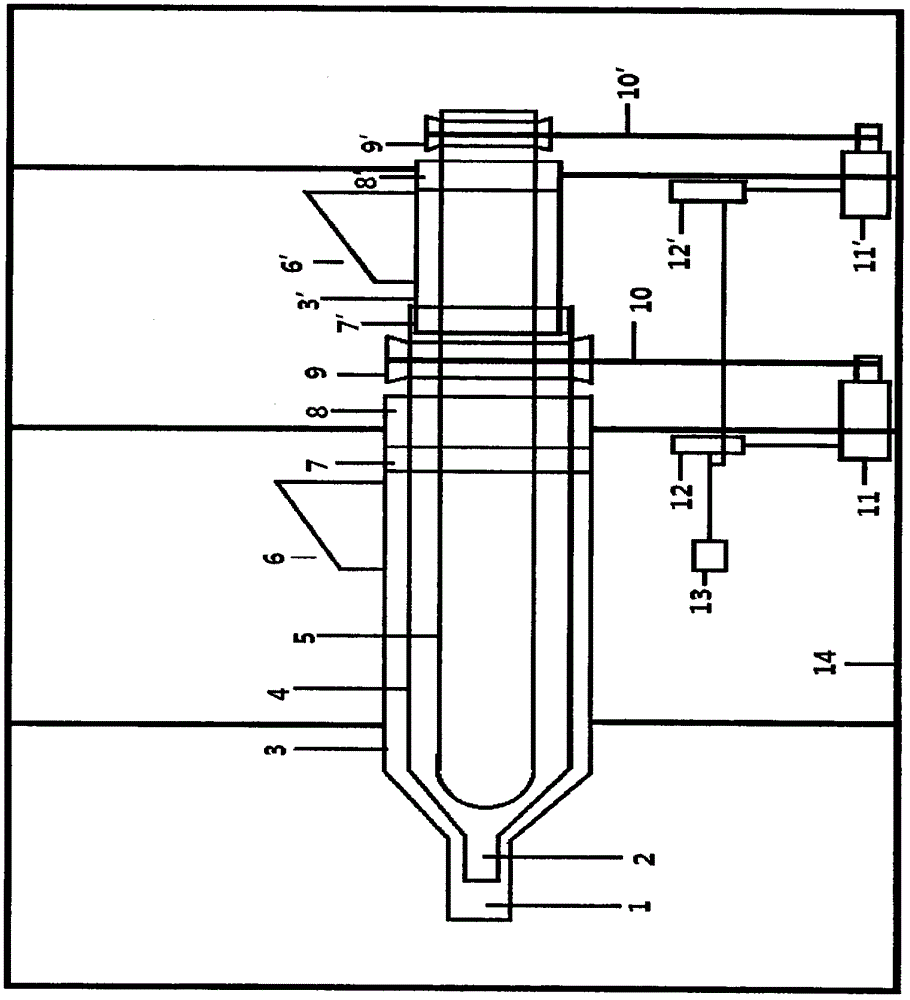

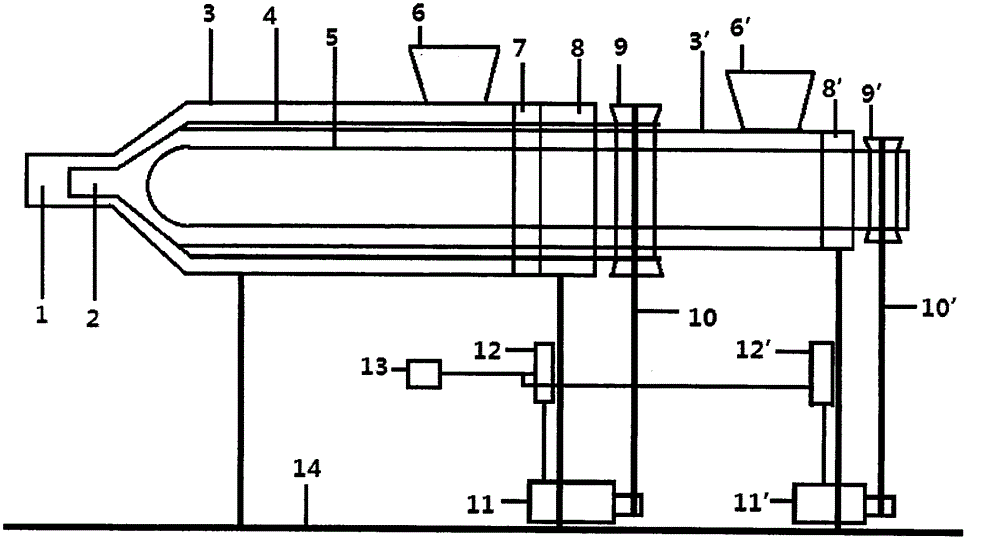

[0029] figure 1 It is a horizontal plan view of the present invention, the fabric enters the fabric cylinder (3) through the fabric feed hopper (6), and the motor (11) drives the pulley (9) on the fabric spiral roller (4) through the belt (10) to drive the fabric spiral The roller (4) rotates, and the fabric helical roller (4) extrudes the fabric in the fabric cylinder (3) through the fabric forming nozzle (1) to form hollow noodles; at the same time, the filling is fed through the filling hopper (6 ') into the stuffing cylinder (3'), the motor (11') drives the stuffing spiral roller (5) via the belt (10'), and the stuffing spiral roller (5) pushes the stuffing from the stuffing cylinder (3' ) into the fabric spiral roller (4), extruded through the filling forming nozzle (2), the fabric and filling are extruded synchronously to form stuffed noodles, and the governor (12, 12') controls the motor (11, 11'), can control the extrusion speed of fabric and stuffing.

[0030] exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com