Method for producing transparent resin composition

A technology for transparent resins and manufacturing methods, applied in the field of manufacturing transparent resin compositions, capable of solving problems such as poor surface hardness or UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

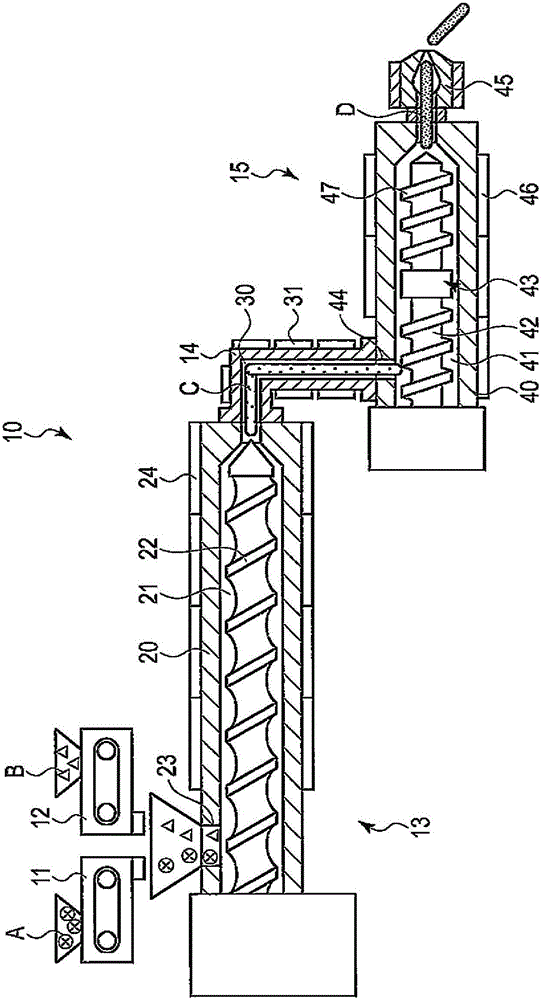

[0056] At first, when implementing the manufacturing method of the present invention, prepare the twin-screw extruder, model TEM-18SS manufactured by Toshiba Machinery Co., Ltd. (Toshiba Machinery Co., Ltd.) whose nominal diameter of the outer diameter of the first screw rod 22 is regulated as 18mm. The twin-screw extruder 13 in the front stage of the manufacturing device 10 . A single-screw extruder, model SE-36SP manufactured by Toshiba Machine Co., Ltd. with a nominal diameter of the outer diameter of the second screw 42 specified as 36 mm was prepared as the single-screw extruder responsible for the post-process of the manufacturing device 10 . In addition, a twin-screw extruder model TEM-18SS and a single-screw extruder model SE-36SP were connected through a single pipe 14 .

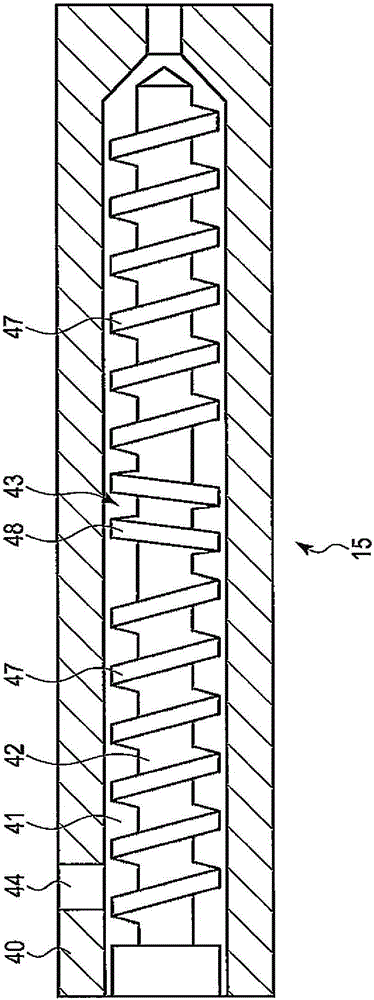

[0057] In the first screw 22 of the twin-screw extruder 13 , the length (effective length) of the first screw 22 with respect to the outer diameter of the first screw 22 is 48 . In the second screw...

Embodiment 2

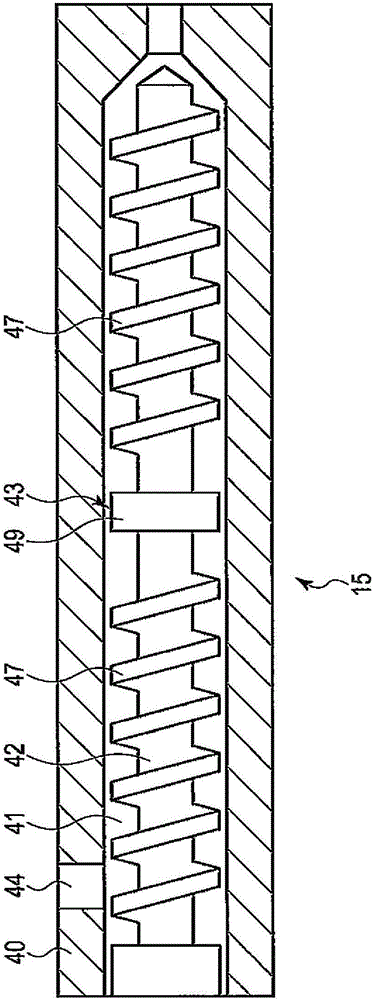

[0061] In Example 2, the melt-mixed resin C was kneaded using the single-screw extruder 15 having the second screw 42 having a different form of the shear processing part 43 . The shear processing part 43 has annular protrusions 49 at two places spaced apart in the longitudinal direction of the second screw 42 . The configuration of the manufacturing apparatus 10 is the same as that of the embodiment except for the single-screw extruder 15 .

[0062] In Example 2, the polycarbonate resin A was supplied to the barrel 21 of the twin-screw extruder 13 from the first raw material supply device 11 at 8 kg per hour, and the acrylic resin B was supplied to the second raw material at 2 kg per hour. The feeding device 12 feeds into the barrel 21 of the twin-screw extruder 13 . In this state, the polycarbonate resin A and the acrylic resin B were melted and mixed at the rotational speed of the first screw 22 at 200 rpm, and the melt-mixed resin C was produced.

[0063] Then make the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com