Preparing method for lithium iron phosphate and lithium vanadium phosphate composite anode material precursor

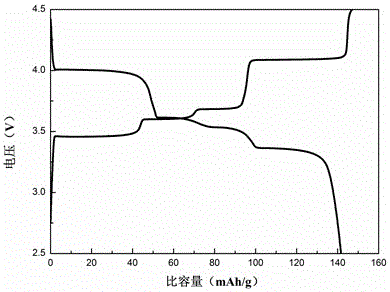

A composite cathode material, lithium vanadium phosphate technology, applied in battery electrodes, electrical components, electrochemical generators and other directions, can solve problems such as the rate performance to be improved, poor ionic conductivity, etc., to achieve good physical processing performance, low cost, diffusion The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Take 4.82g (0.01mol) of ferrous gluconate and 2.44g (0.02mol) of sodium metavanadate and dissolve them in 500ml of deionized water respectively to obtain ferrous gluconate solution (concentration of ferrous ions is 0.02mol / L ) and sodium metavanadate solution, and then the obtained ferrous gluconate solution is mixed with sodium metavanadate solution to react to obtain a reaction solution, and then add PVP (0.013g ), stirring, adding ammonia water to adjust the pH to 6;

[0022] (2) The solution obtained in step (1) was ultrasonically stirred in a water bath at 60°C for 4 hours, and the frequency of ultrasonic stirring was 30KHz to obtain a homogeneous solution, which was then placed in a lined reaction kettle at a temperature of 180°C Reaction 20h;

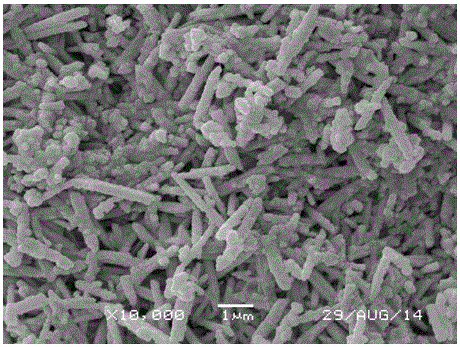

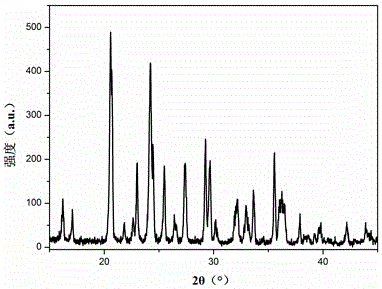

[0023] (3) The reaction solution after the reaction in step (2) was filtered, washed, and vacuum-dried at -0.1 MPa at 90° C. for 8 hours to obtain iron metavanad...

Embodiment 2

[0029] This embodiment includes the following steps:

[0030] (1) Take 9.64g (0.02mol) of ferrous gluconate and 4.88g (0.04mol) of sodium metavanadate and dissolve them in 400ml of deionized water respectively to obtain ferrous gluconate solution (concentration of ferrous ions is 0.05mol / L ) and sodium metavanadate solution, then the obtained ferrous gluconate solution is mixed with sodium metavanadate solution to react to obtain a reaction solution, and then add PVP (0.005g ), stirring, adding ammonia water to adjust the pH to 8;

[0031] (2) The solution obtained in step (1) was ultrasonically stirred in a water bath at 75°C for 2 hours. Under reaction 15h;

[0032] (3) The reaction solution after the reaction in step (2) was filtered, washed, and vacuum-dried at -0.1 MPa at 80° C. for 10 hours to obtain ferrous metavanadate, a precursor of lithium iron phosphate-lithium vanadium phosphate composite positive electrode material.

[0033] Sample test: with 2.54g ferrous met...

Embodiment 3

[0036] This embodiment includes the following steps:

[0037] (1) Take 9.64g (0.02mol) of ferrous gluconate and 4.88g (0.04mol) of sodium metavanadate and dissolve them in 200ml of deionized water respectively to obtain ferrous gluconate solution (concentration of ferrous ions is 0.1mol / L ) and sodium metavanadate solution, then mixed the obtained ferrous gluconate solution with sodium metavanadate solution to react to obtain the reaction solution, then add PVP (0.05g ), stirring, adding ammonia water to adjust the pH to 4;

[0038](2) The solution obtained in step (1) was ultrasonically stirred in a water bath at 90°C for 4 hours, and the frequency of ultrasonic stirring was 20KHz to obtain a homogeneous solution, which was then placed in a lined reaction kettle at a temperature of 250°C Under reaction 10h;

[0039] (3) The reaction solution after the reaction in step (2) was filtered, washed, and vacuum-dried at -0.1 MPa at 120° C. for 5 hours to obtain ferrous metavanadat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com