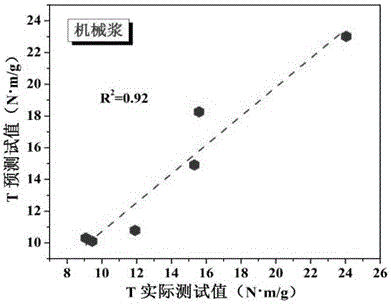

Method for predicting paper tensile strength based on mechanical pulp fiber properties

A technology of tensile strength and fiber characteristics, applied in paper testing, measuring devices, special data processing applications, etc., can solve problems such as acquisition and difficult parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Weigh 75g of mechanical pulp board (dry: 80%), use a thermal deflagging machine for thermal deflaking, and then perform PFI refining, and the refining speed is 1000R, 1500R, 3500R. Determine the water retention value of the slurry. Cut a sample with a width of 15 mm, and after 24 hours of constant temperature and humidity treatment, use the L&W tensile strength tester to test the tensile strength, and then use the formula to calculate the tensile index T of the paper sheet, and use the TMI interlayer bonding instrument to measure the bond strength between the paper sheets. test. The fiber quality analyzer is used to test the fiber shape, the weight-average length of the fiber is measured, and the fiber crimp index C calculated based on the weight-average fiber length w . Substitute the sheet tensile index, the shear bonding strength between fibers, the water retention value of the pulp, the weight-average length of the fibers, and the curl index of the fibers into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com