Measuring method for use in high-temperature thermal buckling transient full-field deformation process of porous sandwich panel

A process measurement and sandwich panel technology, applied in the direction of measuring devices, material thermal analysis, instruments, etc., can solve problems such as poor light conditions, inability to collect speckle images, and affect the quality of image collection, so as to improve correlation and improve experimental results. Accuracy, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

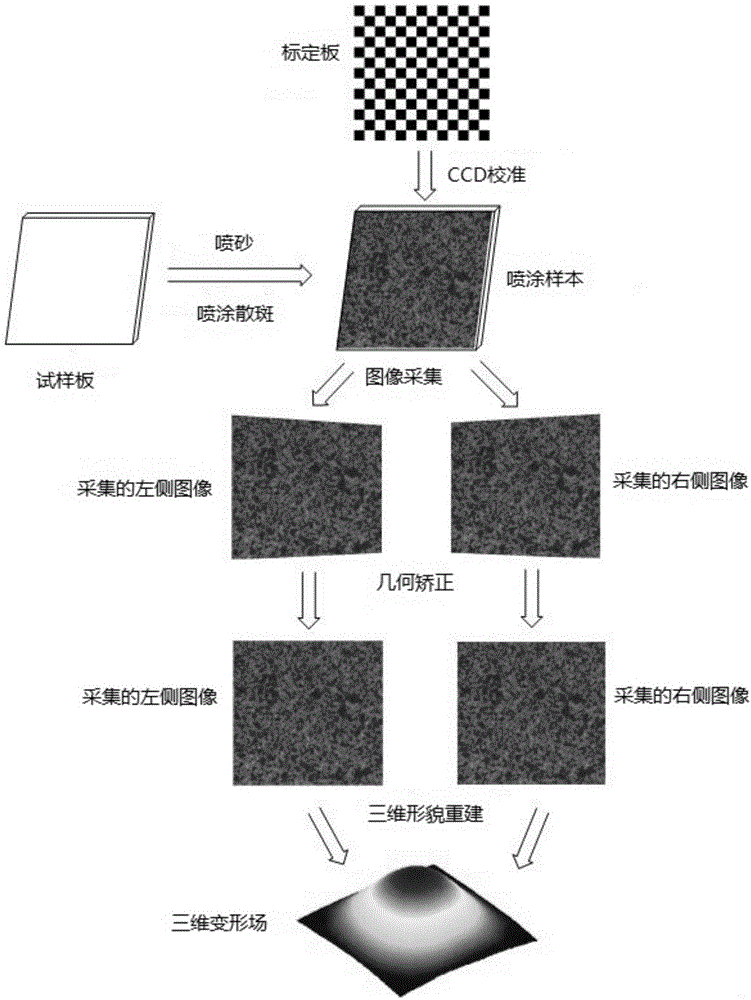

[0037] Such as figure 1 As shown, a method for measuring the transient full-field deformation process of porous sandwich panels under high temperature thermal buckling:

[0038] 1) For speckle production, the surface of the sample plate is sandblasted first, and then the speckle is sprayed on the sample plate with a high-temperature paint that can withstand 800°C high temperature and mixed with an adhesive, and finally the sprayed speckle The panels were left at room temperature for 48 hours.

[0039] For 3D-DIC measurement in high temperature environment, the preparation of high temperature speckle is one of the most important factors affecting the accuracy of the experiment. If the surface of the specimen has no natural texture features, it is necessary to spray a layer of random-sized spots on the surface as speckles for matching. In the high temperature e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com