Novel low-nitrogen pulverized coal combustor

A pulverized coal burner and pulverized coal technology are applied in the direction of burners, burners for burning powder fuel, and combustion methods. Concentrated grading effect and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

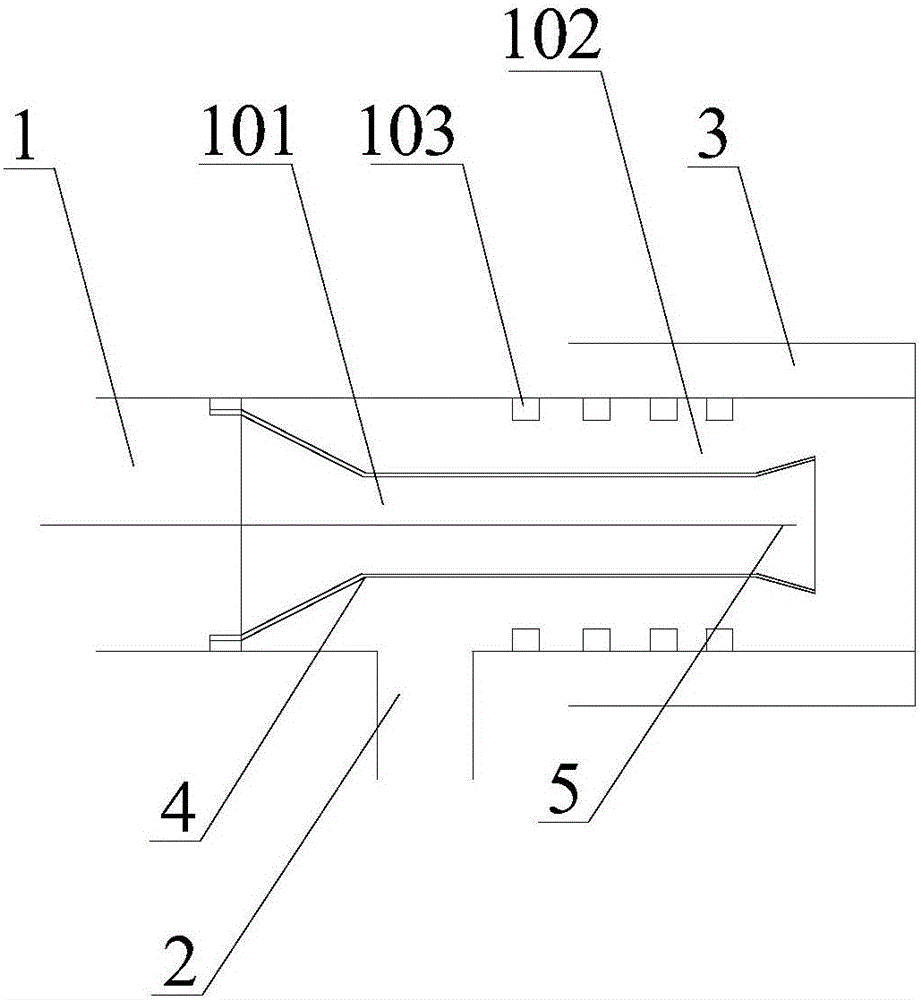

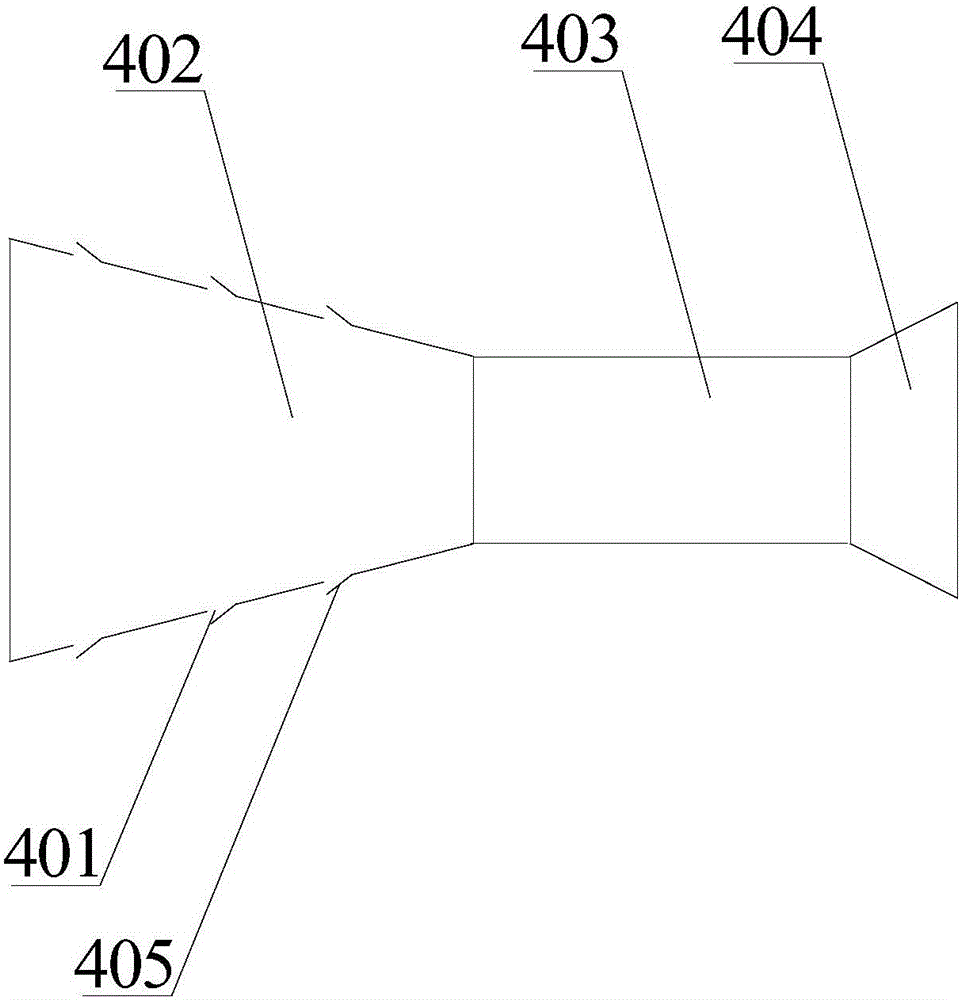

[0015] The main structure of the new low-nitrogen pulverized coal burner involved in this embodiment includes a primary air duct 1, a thick pulverized coal channel 101, a light pulverized coal channel 102, swirl blades 103, a secondary air duct 2, a tertiary air duct 3, coal Powder concentration separator 4, separation part opening 401, separation part 402, flow stabilization part 403, flow diversion part 404, deflector 405 and ignition device 5; secondary air duct 2 is provided at the center of the lower part of the primary air duct 1, A tertiary air duct 3 is provided on the outside of the tail of the primary air duct 1, and a pulverized coal concentration separator 4 threadedly connected with the primary air duct 1 is provided on the inner side of the primary air duct 1. Fire device 5, the central axis of the primary air duct 1 coincides with the central axis of the pulverized coal concentration separator 4, the channel in the pulverized coal concentration separator 4 is the...

Embodiment 2

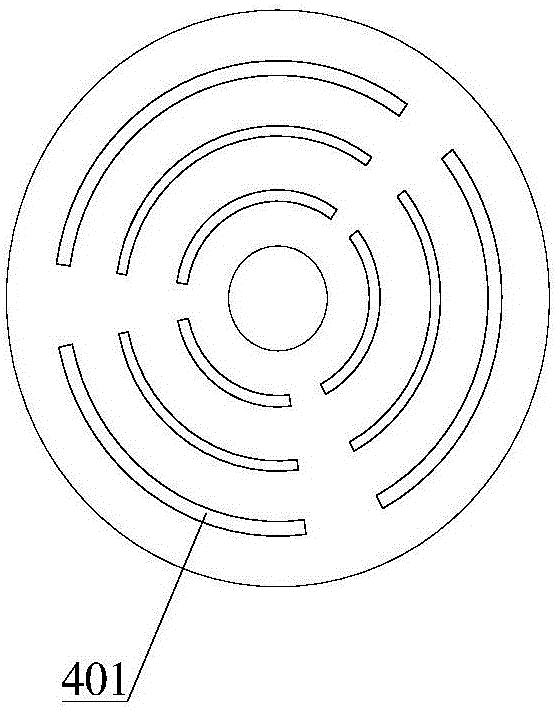

[0019] The main structure of the new low-nitrogen pulverized coal burner involved in this embodiment is the same as that of Embodiment 1, the difference is that the opening 401 of the separation part is helical, so that the pulverized coal entering the light pulverized coal channel 102 is more evenly distributed; the primary air duct 1 The angle between the central axis of the secondary air duct 2 and the central axis of the secondary air duct 2 is equal to 90 degrees.

Embodiment 3

[0021] The main structure of the new low-nitrogen pulverized coal burner involved in this embodiment is the same as that of Embodiment 1, the difference is that the opening 401 of the separation part is in the shape of a dot matrix, so that the pulverized coal entering the light pulverized coal passage 102 is more evenly distributed; the primary air duct The acute angle between the central axis of 1 and the central axis of the secondary air duct 2 is greater than the acute angle between the swirl vanes 103 and the central axis of the primary air duct 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com