Dynamic concrete roadside filling method based on construction waste regeneration

A technology for recycling concrete and construction waste, applied in filling, earthwork drilling, safety devices, etc., can solve the problems of low support capacity, high material consumption, poor sealing performance, etc., achieve efficient recycling, high degree of mechanization, The effect of large support capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

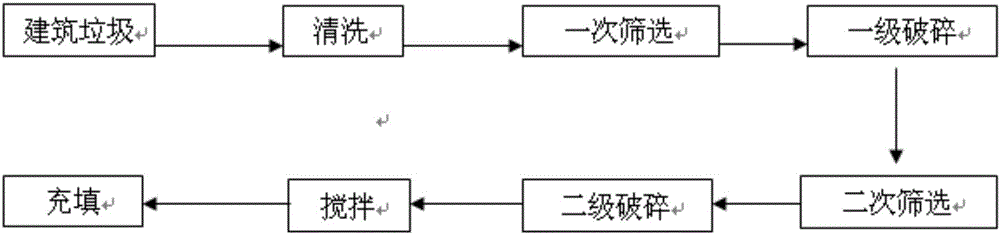

[0031] like Figure 1-2 As shown, a filling method of dynamic concrete roadside based on the recycling of construction waste includes the following steps:

[0032] a. Raw materials, using construction waste to make recycled aggregates;

[0033] B, batching, 50 parts of recycled aggregates obtained in step a, and 10 parts of fly ash, 15 parts of cement, 1 part of sand, and 1 part of quicklime are delivered to the mixer, and the parts are parts by mass;

[0034] c. Stirring. In the mixer described in step b, add water according to the water-solid ratio of 1:2, fully stir the recycled aggregate, fly ash, cement, sand and admixture to obtain recycled concrete;

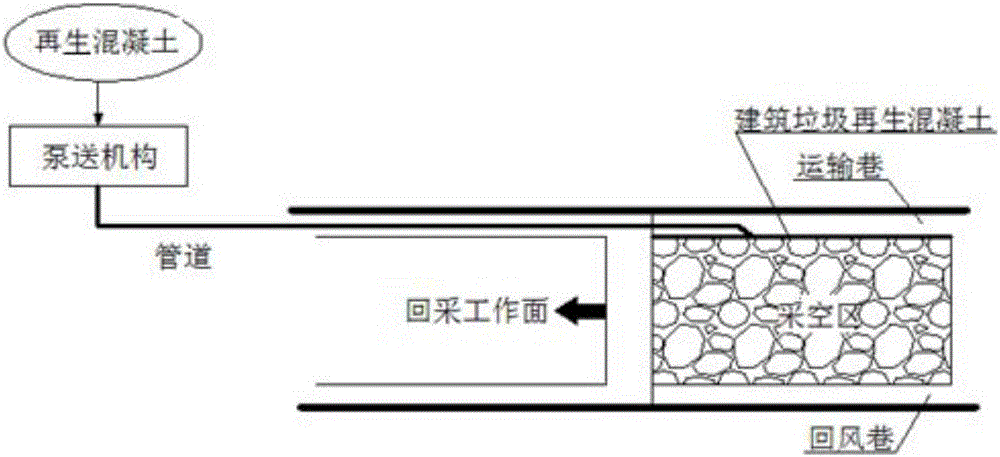

[0035] d, conveying, the regenerated concrete obtained in step c is transported to the filling pipeline beside the goaf in the coal mine through the conveying pipeline; the conveying pipeline is provided with a pumping mechanism, and the power source of the recycled concrete in the conveying pipeline is the pumping mechan...

Embodiment 2

[0047] Basically the same as Example 1, the difference is: b, batching, 54 parts of recycled aggregates obtained in step a, and 12 parts of fly ash, 17 parts of cement, 2 parts of sand, and 3 parts of gypsum are delivered to the mixer, The parts are parts by mass.

Embodiment 3

[0049] It is basically the same as Example 1, the difference is: b, batching, 70 parts of recycled aggregate obtained in step a, and 15 parts of fly ash, 20 parts of cement, 4 parts of sand, 5 parts of the mixture of gypsum and quicklime are transported In the blender, the parts are parts by mass.

[0050] The present invention is based on the construction waste recycling power concrete roadside filling method, by using the construction waste recycled aggregate and fly ash, cement, sand, and admixtures in the mixer to obtain the construction waste recycled concrete after fully mixing, and then using the coal mine pumping mechanism Under the action of the filling pipe, it flows along the filling pipe, discharges and fills into the filling support of the roadside of the goaf; it can achieve efficient recycling of construction waste and realize the effect of "turning waste into treasure"; the roadside filling support of integral pouring The protection has fast resistance increase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com