A spiral atomization jet dust suppression device

A dust suppression device, spiral technology, applied in the direction of safety devices, dust prevention, mining equipment, etc., can solve the problems of high water supply pressure, low droplet atomization efficiency, etc., achieve simple structure, good spray atomization effect, manufacturing and Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

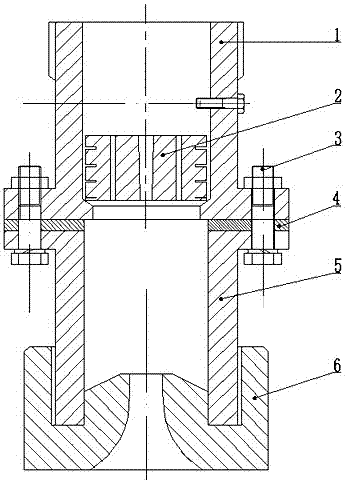

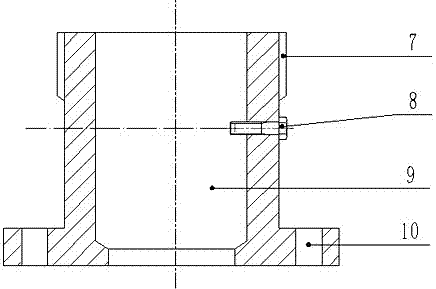

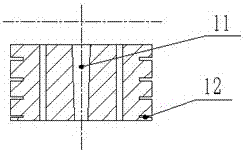

[0024] like Figure 1~6 As shown, a spiral atomization jet dust suppression device includes an upper end cover 1 and a lower end oscillating chamber 5, the upper end cover 1 is a cylindrical structure, the inlet end of the upper end cover is provided with an upper end cover external thread 7, and the upper end cover 1 There is an air intake hole in the horizontal direction in the middle ( figure 1 Bolt 8 is set in the middle, this is under the condition that no air is introduced), the air intake hole is a bolt hole structure, and the center of the upper end cover 1 is provided with a screw valve 2, and the center of the screw valve 2 and the upper end cover 1 are located on the same axis; The inner center of the spiral valve 2 is provided with a tapered hole 11, which is connected with the air intake hole, and through holes 13 are respectively provided at equal distances around the tapered hole 11, which are water inlet holes. The outer edge of the spiral valve 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com