A high-efficiency steel bar cutting machine

A cutting machine and steel bar technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of enlarged cross-sectional surface area of steel bars, difficult to cut, etc., to avoid the lateral area Amplify, enhance the effect, prevent damage to the effect too quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] like Figure 1-Figure 5 Shown:

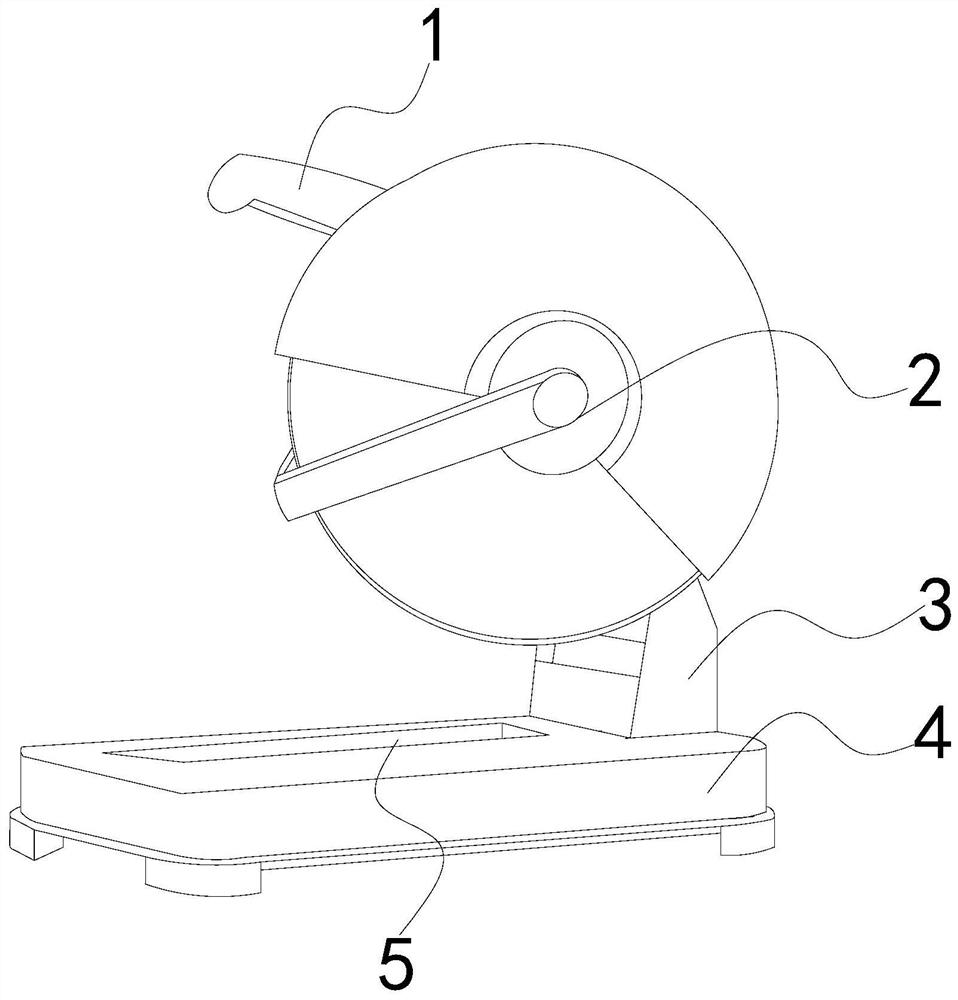

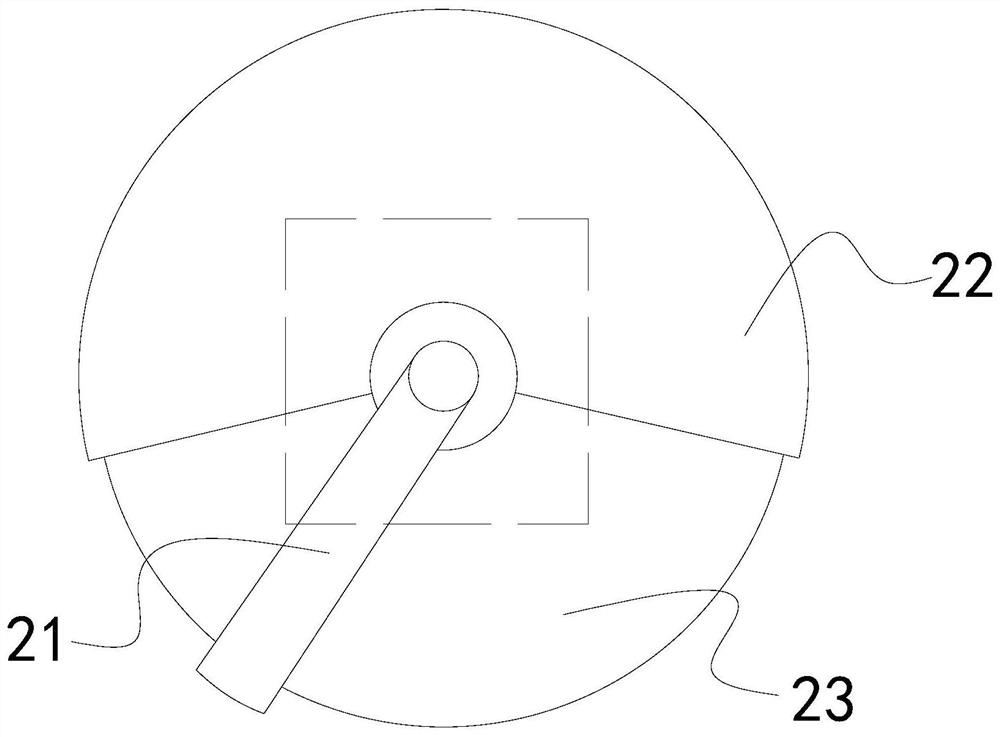

[0024] A high-efficiency steel bar cutting machine of the present invention, its structure includes pressing handle 1, rotating mechanism 2, fixing base 3, placing plate 4, cutting hole 5, described rotating mechanism 2 is installed on the right side of fixing base 3, described pressing handle 1 is located on the upper end of the fixing seat 3, the fixing seat 3 is welded on the surface of the placing plate 4, the cutting hole 5 is located in the middle of the placing plate 4, the pressing handle 1 is installed on the left side of the rotating mechanism 2, the rotating Mechanism 2 is provided with cleaning device 21, protective shell 22, cutting blade 23, and the upper end of described cleaning device 21 is embedded in the central point of cutting blade 23, and described protective shell 22 and cutting blade 23 are located on the same central axis, and described Protective shell 22 is installed in the middle of fixed seat 3, and describ...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

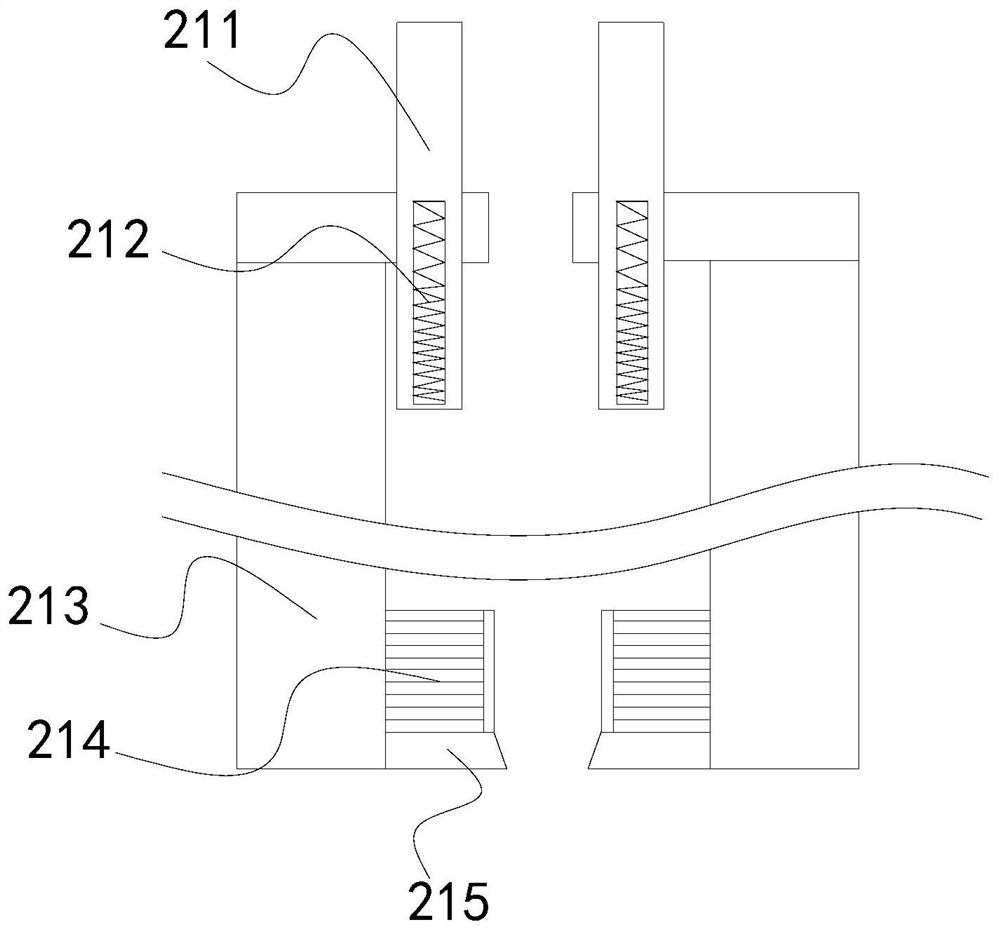

[0032]Wherein, the cleaning mechanism 215 is composed of a cleaning plate e1, a balance bar e2, a first elastic bar e3, a fixed bar e4, a second elastic bar e5, a fixed block e6, and a stressed bar e7. Fixed in the middle of the cleaning plate e1, the left side of the balance bar e2 is attached to the upper and lower ends of the cleaning plate e1, the first elastic rod e3 is installed on the right side of the balance bar e2, and the first elastic bar e3 The right end of the fixed rod e6 is installed on the left side of the fixed block e6, the middle of the first elastic rod e3 is embedded in the upper and lower ends of the force rod e7, and the right end of the fixed rod e4 is attached to the left side of the second elastic rod e5 , the upper end of the fixed block e6 is attached to the lower end of the scraping mechanism 214, the cleaning plate e1 is in an inclined shape, which makes the cut of the cutting blade rub and makes it sharpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com