Lead core tenon limiting damper system

A damper and lead card technology, applied in construction, bridge construction, bridges, etc., can solve the problems of easy oil leakage, failure to popularize and apply, and no damping effect, etc., and achieve a good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

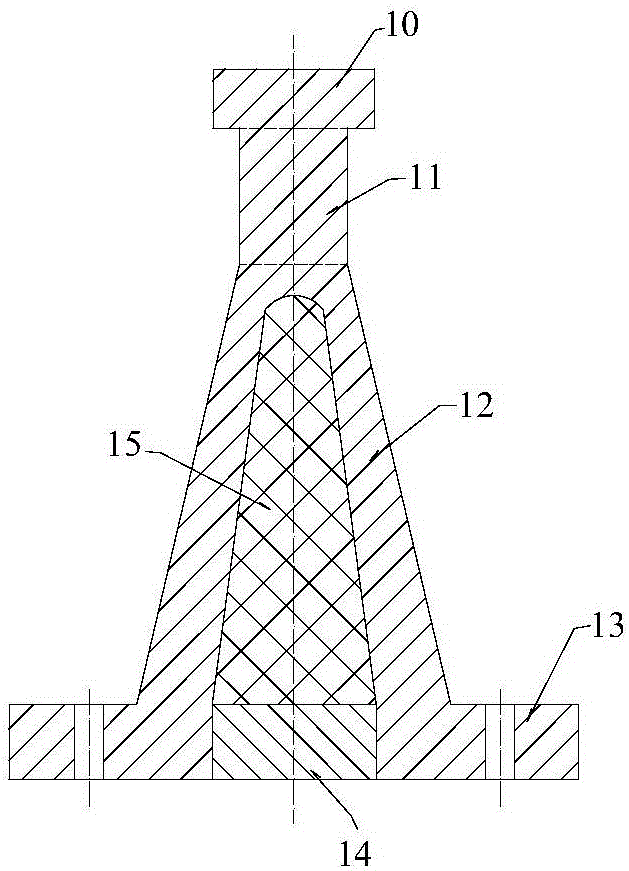

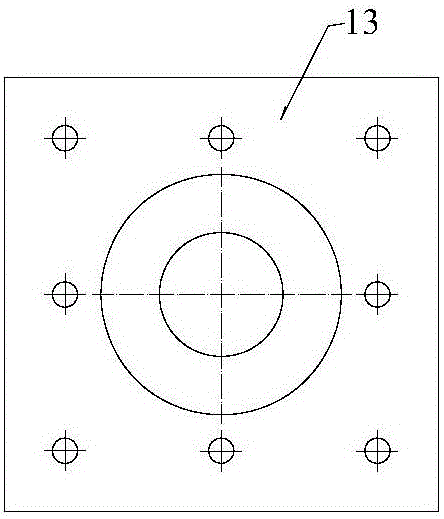

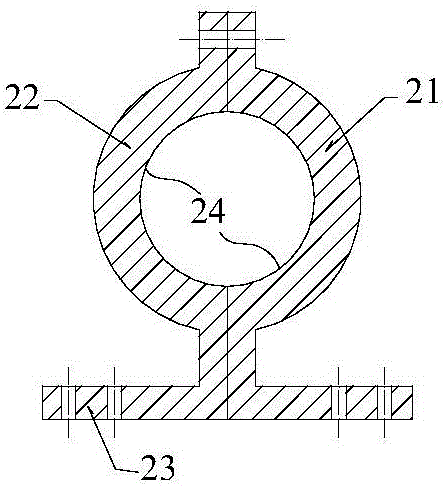

[0016] refer to figure 1 , figure 2 and image 3 , The lead core tenon limit damper system of the present invention includes a steel tenon and a steel buckle. The steel tenon includes a head 10, a buckle fixing section 11, a conical section 12 and an anchor plate 13 from top to bottom, wherein the conical section 12 has a conical cavity, and the conical cavity is filled with With lead core 15. The outer end of the steel tenon is engaged with the buckle fixing section 11 , and the inner end thereof is the bottom plate 23 . refer to Figure 4 and Figure 5 , the steel tenon and the steel buckle are arranged on the outside of the pad stone 32 in the direction of the bridge, and the steel tenon is fixed on the top of the pier body 31 through the high-strength bolt assembly passing through the mounting hole on the anchor plate 13 , the steel buckle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com