Molding preparation method for tackified preform of fiber layered-connection structure

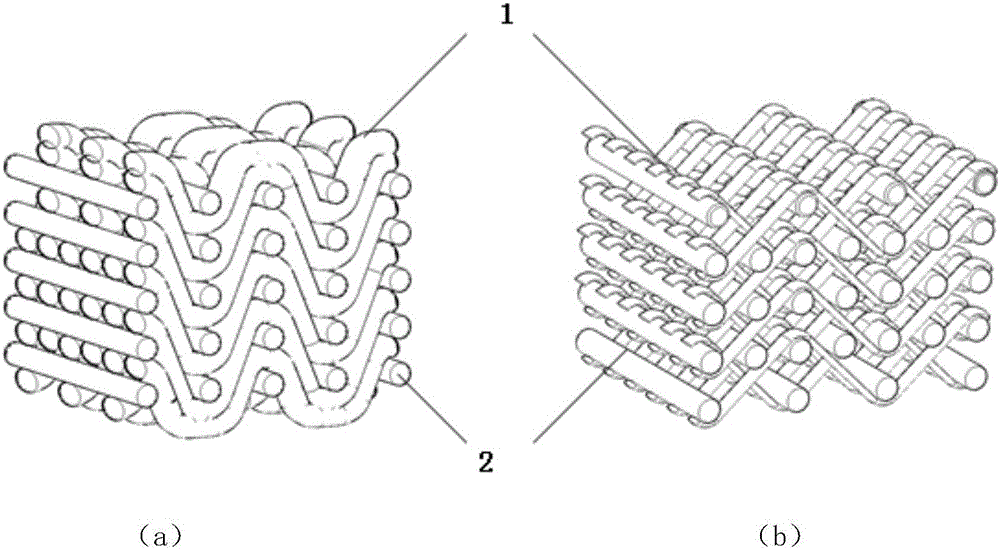

A preform and fiber layer technology, which is applied in the directions of woven fabrics, textiles and papermaking, can solve the problems of unsatisfactory homogeneity and mechanical properties, difficult preparation of preforms, etc., and achieves stable and controllable dimensions and structure. The effect of strong design and complete unit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

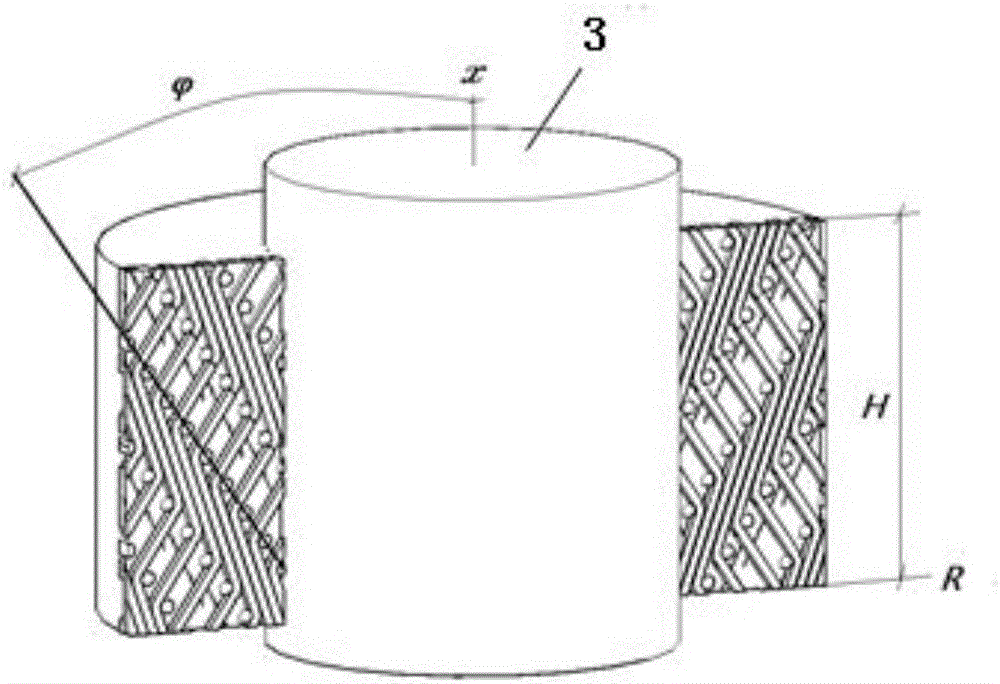

[0050] Tubular fiber layered preforms (such as figure 2 ) as an example, the inner diameter is 500mm, and the thickness of the preform is 28mm. Both the laminated yarn and the laminated yarn are made of quartz glass fiber, which adopts a shallow cross-bending fiber layered structure. The specification of the laminated yarn is 190Tex×4 strands, and the density is 9 strands / cm; the specification of the laminated yarn is 190Tex×7 strands, and the density 2 roots / cm.

[0051] Assuming that the outer diameter of the mandrel (model) of the tubular fiber layered structure preform is R, the thickness of the innermost unit is determined by the number of arrays of double-layered yarns, and the number of weekly units is M, which is the same as the number of arrays of double-layered yarns. The tubular fan-shaped unit (dividing the tubular fiber layered structure preform into equal-sized n equal parts, the smallest unit among them) changes in both the circumferential and radial thickness...

Embodiment 2

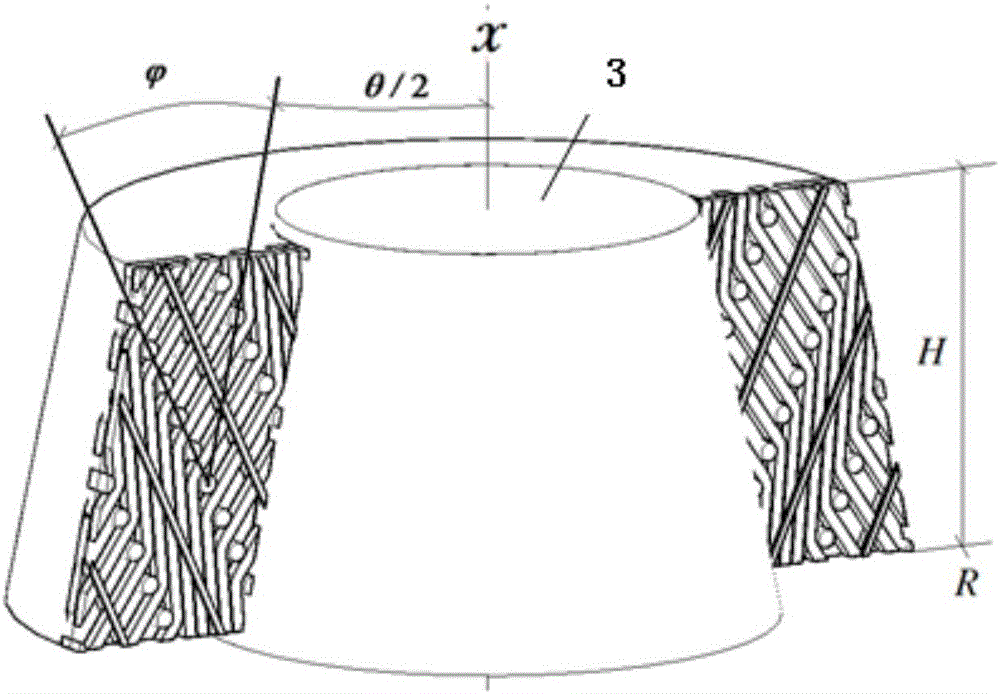

[0061] The preform is connected with tapered fiber layers (such as image 3 ) as an example, the inner diameter of the preform is 500mm, the cone angle (the angle between the busbar and the central axis) is 16 degrees, and the height of the cone section is 500mm. The thickness of the preform is 28mm. The designed double-layered yarn and laminated yarn are all quartz glass fibers, and adopt a shallow cross-bending fiber layered structure. The specification of the double-layered yarn is 190Tex×4 strands, and the density is 9 strands / cm; the specification of the laminated yarn is 190Tex×7 strands. Density 2 / cm.

[0062] The thickness of the innermost unit of the preform determines the number of continuous-layer yarn arrays, and the number of units per week is the same as the number of arrays of continuous-layer yarn bundles. Equally divided, the smallest unit in it) changes with the change of radius and axial size. When the fan-shaped unit is equivalent to a parallelepiped un...

Embodiment 3

[0074] It is basically the same as Example 1, except that the thickness of the preform is 12mm.

[0075] The difference between Example 3 and the Comparative Example is that Example 3 is manufactured according to the mold and integrally formed, while the Comparative Example is offline unfolding and profiling. The epoxy resin of model GT-807A was used to compound the fabrics obtained in Example 3 and Comparative Example, and the mechanical properties of the composited fabrics are shown in Table 1.

[0076] Table 1 Composite performance comparison table

[0077]

[0078] Table 2 Preform Product Accuracy Table

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com