A fully automatic production line and process for metal surface treatment of pyrotechnics bottom shell

A metal surface treatment and production line technology, applied in the direction of metal material coating process, etc., can solve the problems of many people, the action can not meet the process, the manual work is labor-intensive, etc., and achieve the effect of good mechanical strength and reliable grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

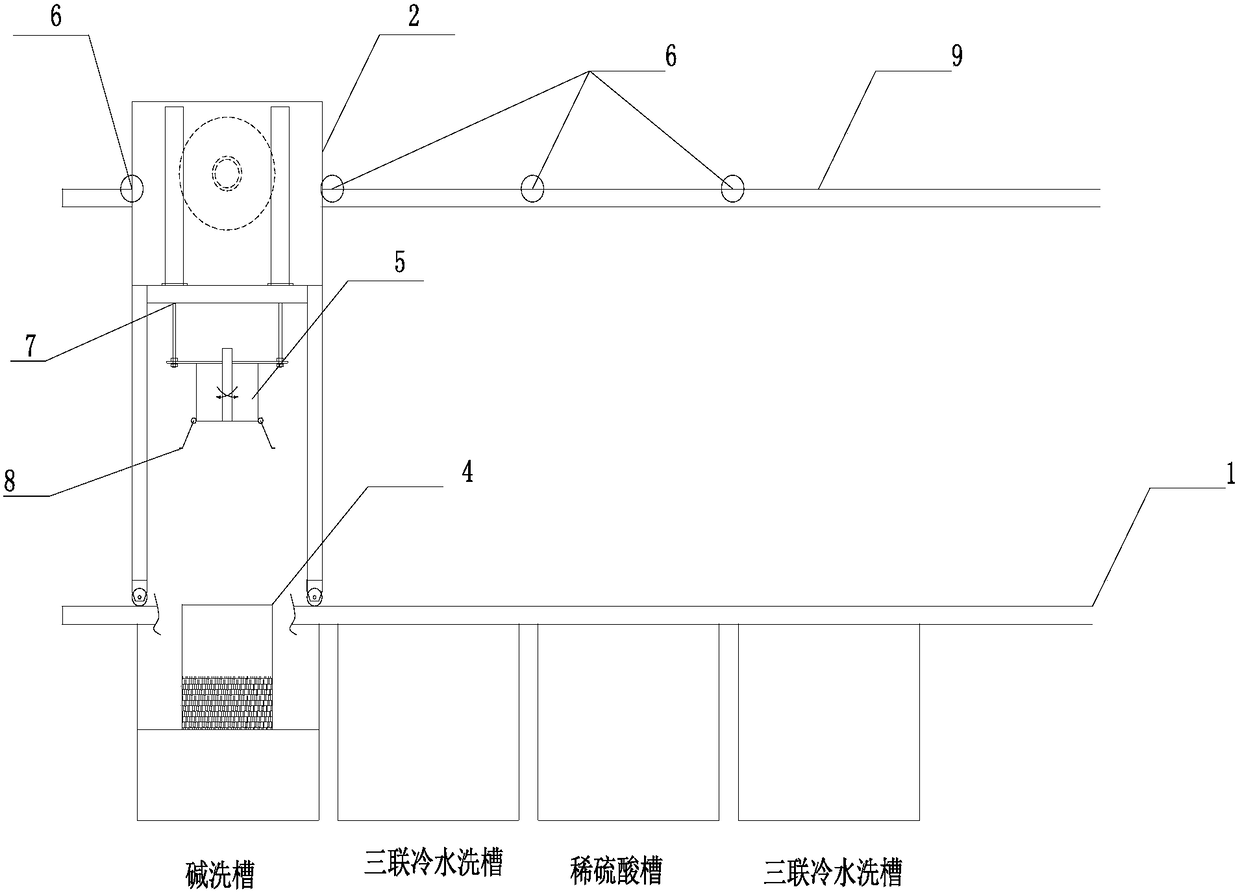

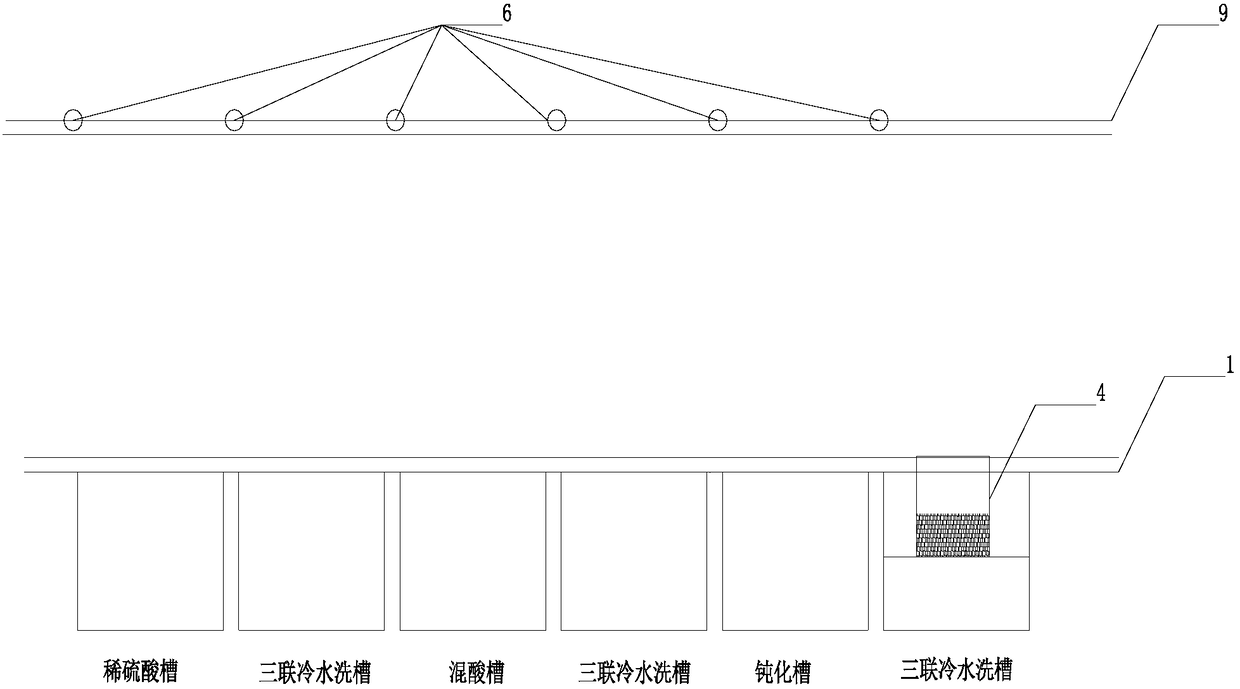

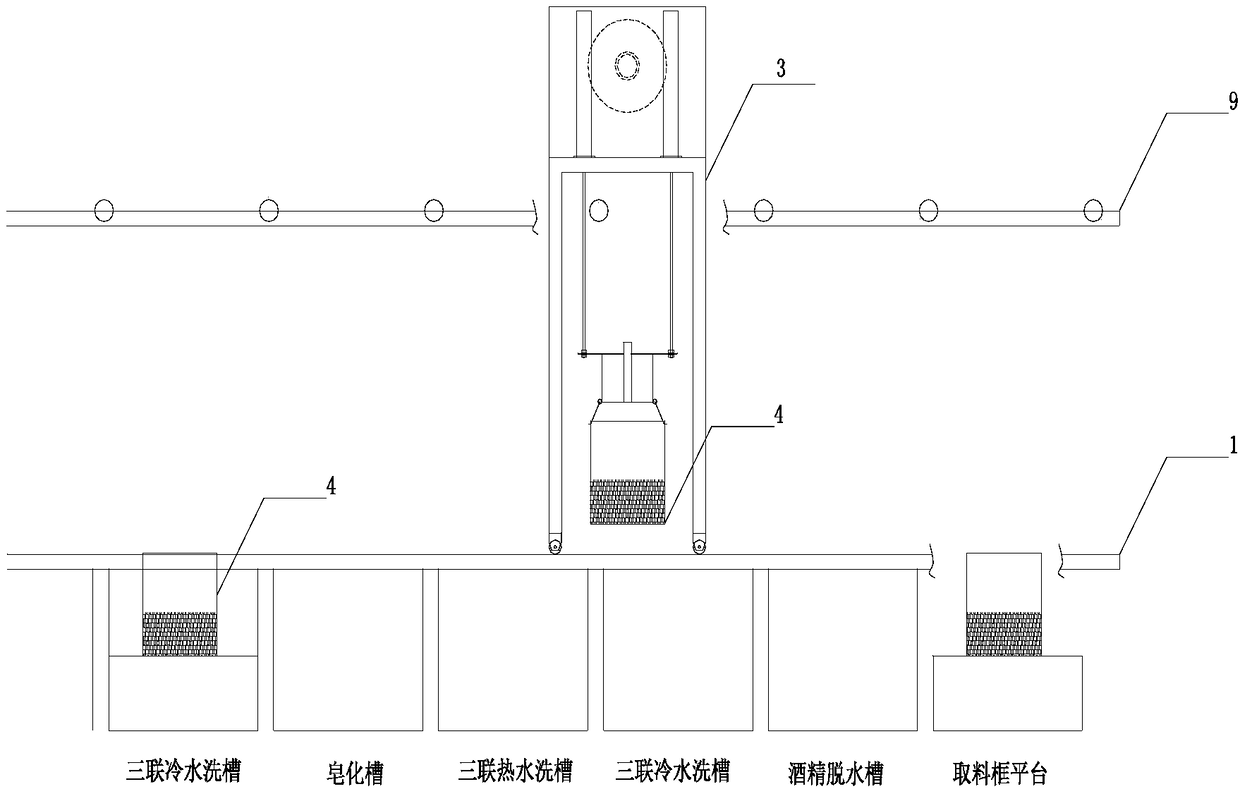

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-4 As shown, the present invention provides a fully automatic production line for the metal surface treatment of pyrotechnics bottom shells. The fully automatic production line includes a driving guide rail 1, a No. 1 driving 2 and a No. 2 driving 3 capable of traveling on the driving guide rail 1, The material frame 4 for placing the primer shell and the metal surface treatment tank unit (comprising a plurality of metal surface treatment tanks) located below the guide rail 1, the No. 1 train 2 and the No. 2 train 3 are respectively provided with The material frame 4 is put into the manipulator 5 for processing in the metal surface treatment tank unit.

[0029] By adopting the above-mentioned automatic production line, the metal surface treatment can be carried out by using the vehicle traveling on the vehicle guide rail 1 to pick and place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com